Development of a Non-circulating Ball Screw for Electro Mechanical Brakes

- Automotive Aftermarket

- Products&Technology

JTEKT Corporation (hereinafter JTEKT) has developed a "Non-circulating Ball Screw" assuming application on electro mechanical brakes (EMB). EMB is a braking method that uses an electric motor for the drive source pressing the disc brake piston instead of hydraulics. EMB is used on electric vehicles (EV), hybrid electric vehicles (HEV), etc. and helps to reduce vehicle weight, lower CO2 emissions, and enhance comfort.

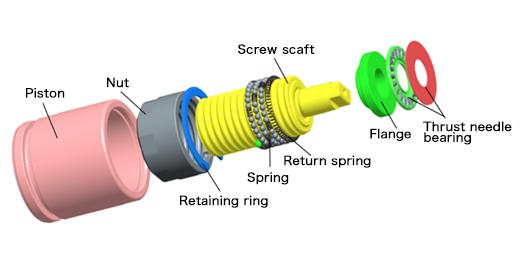

[Image of New Product]

Development Background

In recent years, there has been strong focus on quickly shifting to electrification and autonomous driving cars by the automobile industry in response to environment regulations, and this has led to a shift from hydraulic to electronic control of auto parts as well. EV and HEVs use a combination of regenerative braking and friction braking. Regenerative braking slows down a vehicle by converting the force rotating the motor to electric energy, and control by friction braking, which maximizes this "energy regeneration," helps to improve a vehicle's fuel efficiency. By using friction braking on ball screws, it is possible to improve the efficiency of energy regeneration and braking performance.

Features of the New Product

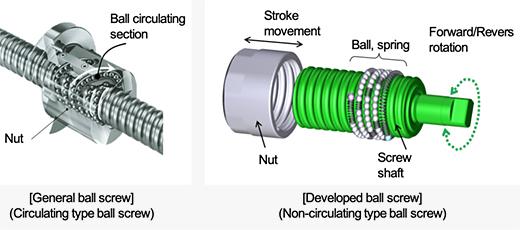

Ball screws convert the rotating motion of an electric motor to linear motion of the brake piston with good efficiency. Generally-speaking, the mainstream form of ball screw has a circulating mechanism to prevent balls from dropping out of the raceway during linear motion. There are various types of circulating mechanisms, however all of them come with the demerit of the ball screw itself being large due to accounting for the circulating section.

This time, JTEKT focused on the fact that EMBs require a short linear motion distance during braking, and developed a smaller ball screw able to continue rotating even without a circulating mechanism by placing a spring between the balls.

Moreover, by improving the grease to prevent efficiency reduction caused by oil film shortage, sufficient durability is secured and a maintenance-free ball screw is realized.

JTEKT Corporation has newly created a tagline "Key of your operation Koyo" for the bearing brand "Koyo". JTEKT will continue contributing to every industry as an indispensable partner to solve customers' problems through working with customers and to provide benefits.