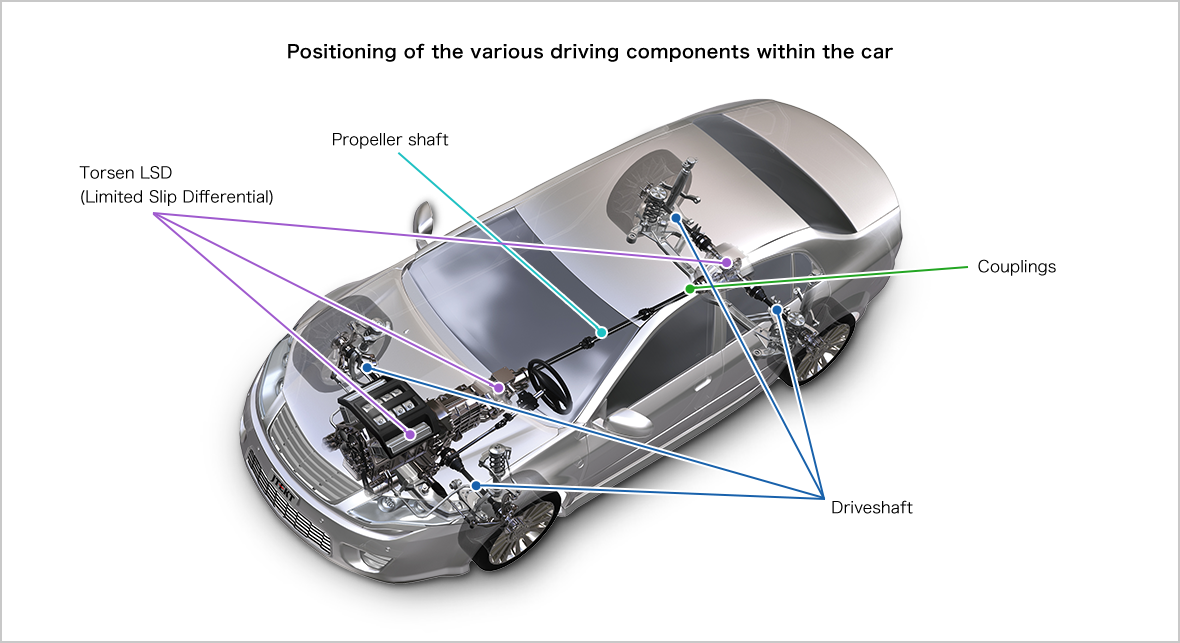

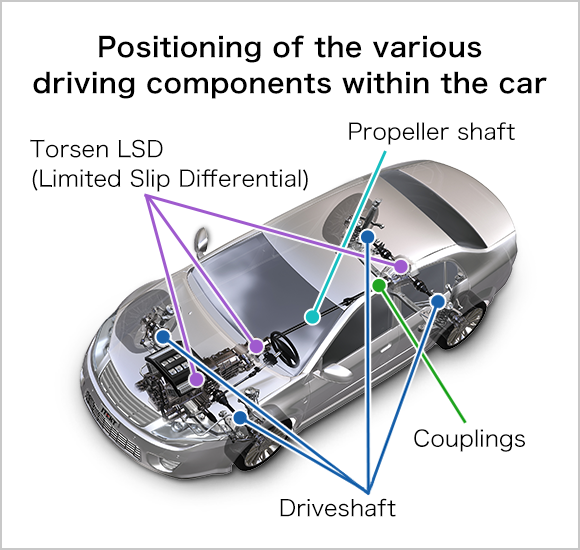

Drive line

Applying Our Core Technologies Focused on Size and Weight Reduction, and Hydraulic and Electronic Control Technologies

The driving force generated at the engine is transmitted to four tires with this mechanism.

The driving force must be distributed to four tires according to the terrain and traveling state to realize low fuel consumption and stable travel.

JTEKT applies multiple core technologies while centering on the bearing technologies and hydraulic/electronic control technologies, so that we have products boasting the top share.

PRODUCT LINEUP

Driveshaft

The drive line maintains the vehicle speed and transmits the driving force even when the axle or tire is placed at an odd angle.

Propeller shaft

Engine rotation is transmitted to the differential.

-

Propeller shaft

A three-partition structure and slide type constant-velocity universal joint are adopted to improve calmness.

A variety of products are provided according to the maximum transmitted torque. -

Cross bearing for propeller shafts

A variety of products are provided for from light vehicles to heavy-duty large trucks.

Torsen LSD (Limited Slip Differential)

The driving force transmitted from the propeller shaft is redirected 90 degrees and distributed between left and right axles according to the terrain and traveling circumstances.

-

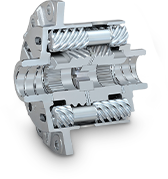

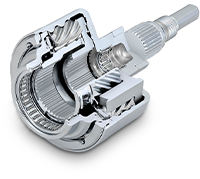

Type-A Torsen

The torque distribution ratio used for the rear differential and so on of the rear-drive sports vehicles is high with this model.

The high-speed cornering and bad-terrain driving limit performance is improved to achieve generous high-dimensional drivability.For more details...

-

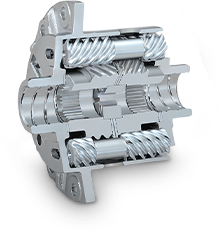

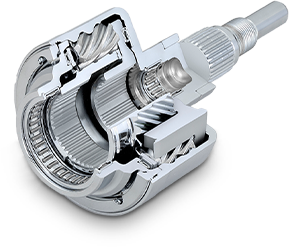

Type-B Torsen

Immediate torque distribution suitable for the terrain not available with open differentials is possible.

While the advantage of the original response of Torsen is enjoyed, this multi-purpose model supports various applications with wide adaptability ranging from the front differential to the rear differential.For more details...

-

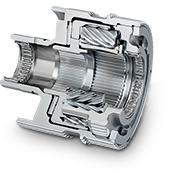

Type-C Torsen

Through adoption of a planetary gear type, size reduction and weight reduction are aimed at and, with uneven torque distribution between the front and rear, high driving stability is brought to the vehicle with the center differential devoted to four-wheel-drive vehicles.

For more details...

-

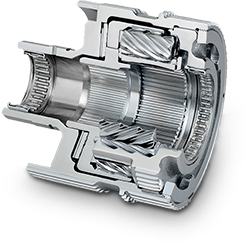

Type-C compact Torsen

A compact size and light weight are realized through both optimized design of components and reduction of the number of parts for Type-C Torsen.

"TORSEN" is a registered trademark of JTEKT.

Couplings

Installed in an FF vehicle, it distributes the driving force to the front and rear axles.

-

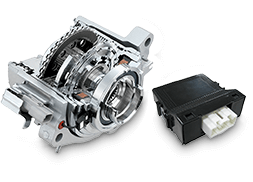

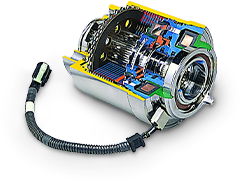

Intelligent torque controlled coupling(ITCC)

Difference in rotation between the front and rear axles is detected and electronic control makes it possible to distribute the torque optimally for the driving state and terrain between the front and rear axles.

Because the center differential mainly adopted in full-time four-wheel-drive vehicles becomes unnecessary, size reduction and weight reduction can be realized, contributing to improved fuel consumption.For more details...

-

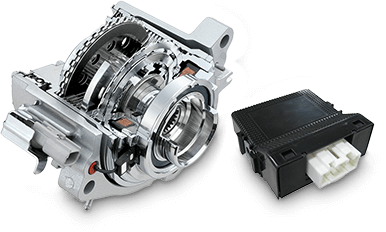

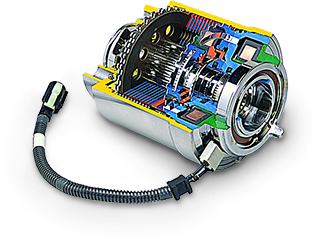

4WD coupling (E-RBC) with electromagnetic lock

Selection between the standby four-wheel-drive and direct-coupling four-wheel-drive modes can be made according to the decision of the driver with a compact four-wheel-drive coupling for RV vehicles with an electromagnetic lock.

In the Auto mode, it functions in the standby four-wheel-drive mode while you can switch to the direct-coupling four-wheel-drive mode with switch operation even during travel on bad terrains where a large driving force is necessary.

"ITCC" is a registered trademark of JTEKT.