Case studies

Toyota Motor Corporation

Applying ONI BEARING technology from road bicycles for racing wheelchairs

Racing wheelchairs

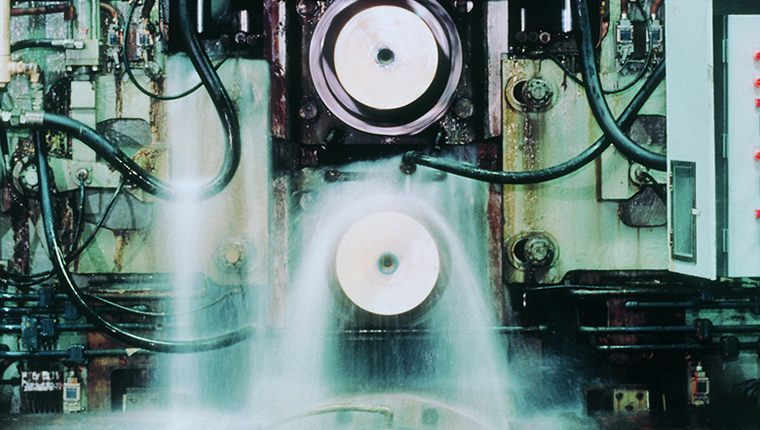

Steel manufacturers

Using bearings for multi-roll mill backup rolls with high sealing performance enables cleanup times to be shortened and safety increased!

Multi-roll mills for steel production equipment

Araya Industrial Co., Ltd.

Contributing to the World’s Best Riding in 2021! Development of a Bearing for Racing Bicycle Wheels

Racing bicycles

Motor manufacturers

Ceramic Bearings for Non-Magnetic Ultrasonic Motors

MRI (Magnetic Resonance Imaging) electric motors

Optical film manufacturers

Bearings Used to Support Rollers in Equipment for Manufacturing Optical Films

Optical film manufacturing equipment

Plating manufacturers

Bearings to Support Rollers in Plating Tanks

Rollers in plating tanks

Semiconductor manufacturers and food manufacturers

Corrosion-Resistant Bearings That Can Withstand a Wider Range of More Extreme Environments

Equipment for use in various manufacturing processes, etc.

Steel manufacturers

Development of an Oil Seal for Steel Rolling Mills

Drive shafts

Manufacturers of agricultural and construction machinery

Development of the NK Bearing: The Next Generation in Bearing Service Life

Agricultural and construction vehicles, etc.

Development of a Low Idling Torque One-Way Clutch

Robot and reducer manufacturers

Development of a Greatly Miniaturized Tapered Roller Bearing

Reducers

Industrial motor and household electronics manufacturers

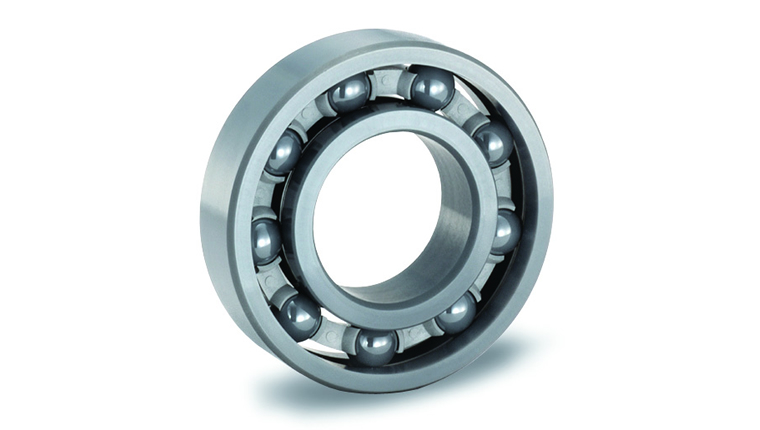

Development and Mass Production of Motor-Use Deep Groove Ball Bearings with Optimized Sound Output: Reduction of Sounds That Can Be Unpleasant to the Ear

Industrial motors

Hydraulic pump and motor manufacturers

Development of Cylindrical Roller Bearings with PPS Cages: Increased Heat Resistance and Corrosion Resistance to Expand the Range of Applicability

Hydraulic pumps

JM, a company that sells bearings for skateboards Brand name: NINJA (“NINJA” is a registered trademark of JM Co., Ltd.)

As Seen on the NHK Show “Extreme Awesome Techniques!” Bearings Used in Skateboards"

Skateboards

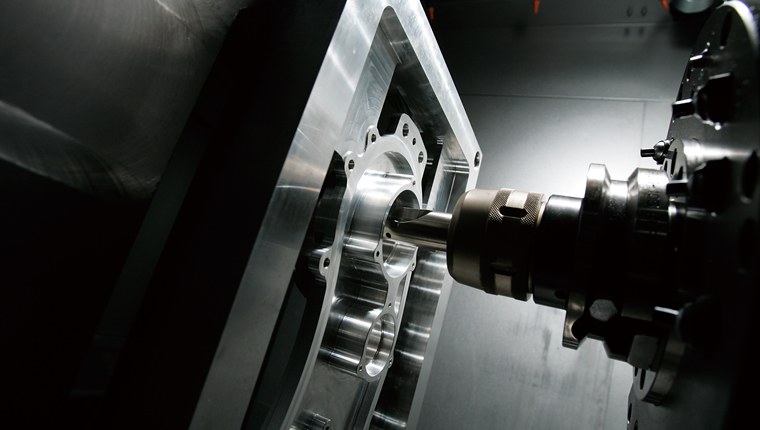

Domestic and foreign manufacturers of machine tools and spindles

High Ability Series Development and Mass Production of Grease-Lubricated Angular Contact Ball Bearings with Lowered Temperature Rise for Machine Tool Spindles

Machine tool spindles

Domestic and foreign steel manufacturers (steel industry, steel production equipment) in possession of sintering equipment

Development of Intermediate Seals and Bearings for Sintering Machine Pallet Cars for Steel Production Equipment 2.5 Times Longer Unit Service Life and a Dramatic Increase in Productivity

Bearings for sintering machine pallet cars for steel production equipment

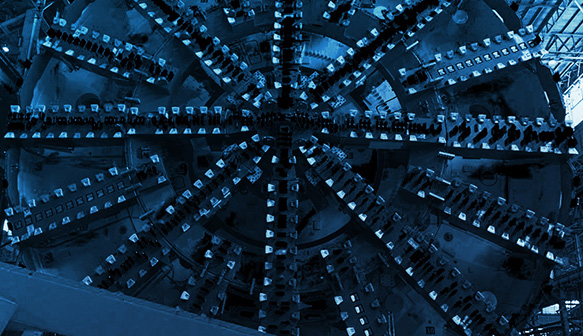

A company that digs tunnels

With a Diameter of 7.7 m, It's Among the Largest in Japan! Development of a Segmented Triple-Row Cylindrical Roller Bearing for Use in a Shield Excavator for High-Depth Underground Construction

Development of a segmented triple-row cylindrical roller bearing

Motor manufacturer

Stable insulation performance! The long-life product for electric pitting was realized by new ceramic ball bearing.

New Ceramic Ball Bearing for Motor

Robot parts manufacturer

Contributing to the further enhancement of robot performance! A bearing achieving both size reduction and higher capacity (longer life)

Ultra-Thin Deep Groove Ball Bearing

(high load capacity type)

Printing machinery manufacturer

80% less uneven rotation! (compared with a planetary gear) A precision reduction gear adopting Koyo bearing technology

Traction Drive Unit

(reduction gear for high-accuracy feed)

Major heavy industry manufacturers, chemical manufacturers, research institutions and many more

Practical realization of the world's first ceramic bearing in 1984 Reliable, corrosive-resistant and suitable for use in solutions

Corrosion Guard Pro Bearing