(LFT series) JTEKT develops the 5th generation Low-Friction-Torque tapered roller bearing"LFT-V"

- Automotive Aftermarket

- Products&Technology

JTEKT Corporation(hereinafter JTEKT) has developed the 5th generation Low-Friction-Torque tapered roller bearing"LFT-V"used in transmissions, pinion support of differential units and other applications.

LFT-V offers world's number one low friction torque performance*2 and the lightest in our tapered roller bearing-LFT series.

We are going to proceed with the proposal of LFT-V as a product that contributes to the low fuel consumption, high efficiency of automobiles, and moreover corresponds to electric units.

【Photo of the developed bearing】

【Photo of the developed bearing】

*1 LFT is the abbreviation for Low-Friction-Torque, and is a registered trademark of JTEKT Corporation.

*2 According to our research.

1.Background of the development

Tapered roller bearings (hereinafter TRB) are employed on lubrication of automotive driveline components such as transmissions and differentials. However, since the rollers of TRB have a pumping function, there was an issue that the agitation loss of lubricants applied to sections (such as differential drive pinion shaft support) with high lubrication viscosity, high lubrication amount, or high rotation becomes large.

JTEKT put a special focus on the reduction of the agitation loss of the lubricant, developed and commercialized "The 3rd generation Low-Friction-Torque TRB (LFT-III)"and "The 4th generation Low-Friction-Torque TRB (LFT-IV)", which have significantly reduced torque by suppressing the lubricant amount that flows into the bearing.

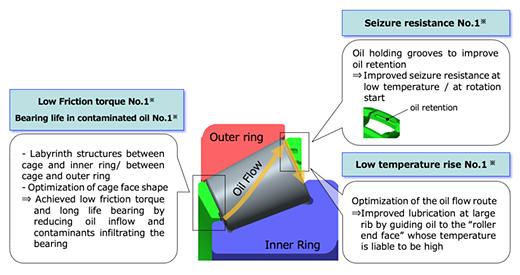

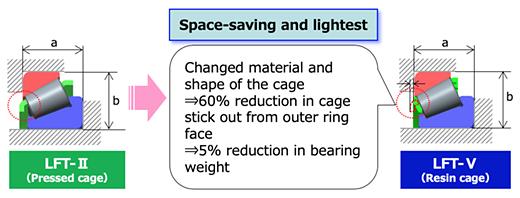

To meet the demands for further automobile low fuel consumption, we have developed "The 5th generation Low-Friction-Torque TRB(LFT-V)"this time. This product has achieved that world's number one low friction torque by optimizing the resin cage shape and optimally controlling the lubricant amount that flows into the bearing. Furthermore, grooves of the cage to hold oil, which improve seizure resistance at rotation start and at low temperature. In addition, we have also optimized the oil flow route inside the bearing in anticipation of the recent trend toward low-viscosity oil and the reduction of oil level. By doing so, the bearing temperature rise can be lowered.

2.Features of the New Product

Number one*3 performance in TRB-LFT series by optimizing the shape of resin cage.

*3 Number one:Performance comparison in JTEKT's TRB-LFT series

Space-saving and Low-Friction-Torque design without changing peripheral parts, and moreover the lightest weight in TRB-LFT series.

Baring performance

| Item | Performance (vs. LFT-II*4) |

|---|---|

| Friction torque | 60% reduction |

| Bearing temperature rise | 15% reduction |

| Bearing life in contaminated oil |

2 times |

| Seizure resistance at low temperature | Oil-free seizure time:2.2 times |

*4 LFT-II:JTEKT's standard low-friction-torque models

3.販売計画

[Start of volume production] Planned in 2022

[Sales target] 1.7million sets/Year(in 2025)

[Customers] Domestic and global automakers and transmission suppliers etc.

4.Reference: Generational evolution of TRB-LFT series

| Features | Torque reduction (vs. LFT-II) |

|

| LFT-Ⅱ | Special crowing of inner/outer ring raceways | --- |

| LFT-Ⅲ | Optimization of inner specifications, reduce oil inflow | ▲40% |

| LFT-Ⅳ | Change to resin cage, further reduce oil inflow | ▲55% |

| LFT-Ⅴ | Optimization of resin cage shape, control that oil inflow and oil flow route | ▲60% |

JTEKT Corporation has newly created a tagline "Key of your operation" for the bearing brand "Koyo". JTEKT will continue contributing to every industry including automotive manufacturers as an indispensable partner to solve customers' problems through working with customers and to provide benefits.