- Customer

- Motor manufacturerA major manufacturer of environmental equipment used under various conditions.

- Products for this case study

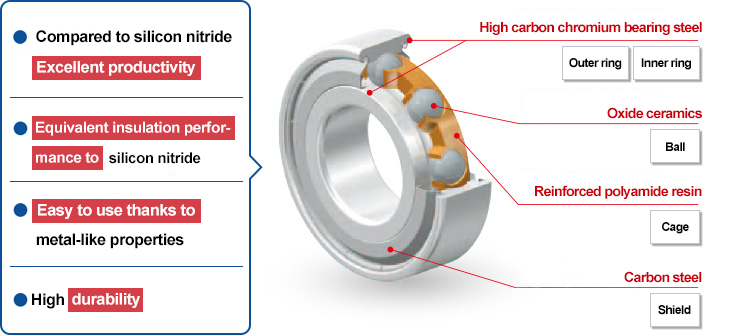

- New Ceramic Ball Bearing for Motor

Application > Inverter motor, fan motor, etc.

Electric pitting is a common issue amongst manufacturers dealing in the products that should not be broken.

For example, motors used to power public infrastructure, and hospital equipment require the suitable quality, and unexpected break down cannot be accepted, so countermeasure for electric pitting is necessary.. In order to avoid any issue with by electric pitting, This company adopted JTEKT's ceramic ball bearings Then, they have been very satisfied with high level of quality of insulation and durability of our bearings.

However, because of the attribute of the materials from these types of ball bearings were highly costed to produce. Obviously, not only this company but the whole motor industry demanded "more affordable ceramic ball bearing".

Due to the attribute of electric (inverter-driven) motor, hazardous voltage can be generated by high-frequency electric current in operation. Since the inside of the bearing is insulated by the oil film by grease, when the voltage accumulates and exceeds a certain amount, spark (discharge) occurs through a very thin oil film at the rolling contact part. The damage to the bearing in such an occasion is called electric pitting. Once electric pitting occurs, it will cause damage to the ball and cage, causing abnormal noise and damage.

JTEKT is a pioneer of ceramic bearings, and as a company having the "Koyo" brand,

we have been thinking to have more of the customers that could be satisfied with the quality of our ceramic bearing.

Motivated by that thought, JTEKT developed the new products using new ceramic materials.

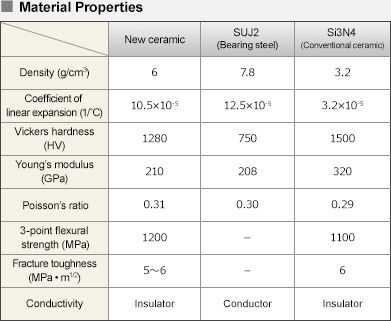

Through trial and error process, We focused on a particular type of ceramic material.

This material is relatively easy to process and has sufficient strength as balls for bearings.

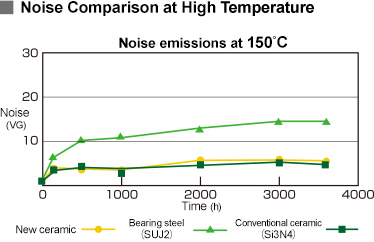

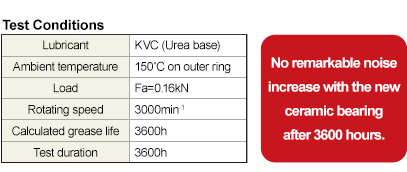

Through several evaluation tests, the practical utility as a bearing for motor was confirmed. Here we have completed a new product that can provide ceramic insulation and durability reasonably.

Maintaining stable quality in facilities and occasions that should not break suddenly

JTEKT immediately proposed the new ceramic ball bearing the customer it was developed, and the customer adopted the product right away.

It performed as expected for its performance and quality then the customer was satisfied with the result of reduced cost.

Bearing with the newly developed ceramic ball.

Reasonable price while having insulation and durability equivalent to conventional bearings

Moreover,

Since the coefficient of linear expansion (*) is close to that of the inner and outer rings, the change in the internal clearance of the bearing due to the temperature change is small and it also have the advantage that it is hard to deteriorate even in places with severe temperature change.

- * Increase in length when temperature is increased by 1℃

When the new ceramic ball bearing was developed, we were quite sure that it would go down in our corporate history as a great product.

I remember that I made the proposal with the thought that " I'll be the first sales person to introduce this item!"

I truly appreciate the fact that they adopted our new ceramic bearing.

Bearings can be applied in any place where needed but we feel sure that this reasonable product can be used easily in wide range of applications.