- Customer

- A company that digs tunnels

- Products for this case study

- Development of a segmented triple-row cylindrical roller bearing

Application > Construction of very deep tunnels

Used in the Growing High-Depth Infrastructure Construction

When constructing expressways in urban areas, it is necessary to keep the impact on both the natural environment and the community environment (such as existing buildings and facilities) to a minimum. For this reason, developers are more and more aiming not to build above ground but rather to dig tunnels at great depths that are not affected by things like basements and the foundations of buildings.

When a cutter shield excavator for high-depth underground construction was required for the construction of a tunnel (total length 16.2 km) on the Tokyo Outer Ring Road connecting the Kan-etsu Expressway to the Tomei Expressway, triple-row cylindrical roller bearings were needed to support the rotation of the excavator.

JTEKT has numerous achievements and a high level of credibility when it comes to providing triple-row cylindrical roller bearings for a variety of excavators big and small, such as the excavator used in the construction of the Tokyo Bay Aqua-Line.

Large-size triple-row cylindrical roller bearings require segmented design, and we are the only Japanese manufacturer capable of producing such bearings; as such, our technical skill was recognized on this occasion, and our segmented triple-row cylindrical roller bearings were selected for use in the excavator.

Segmented Delivery of One of the Largest Bearings in Japan! On-Site Assembly!

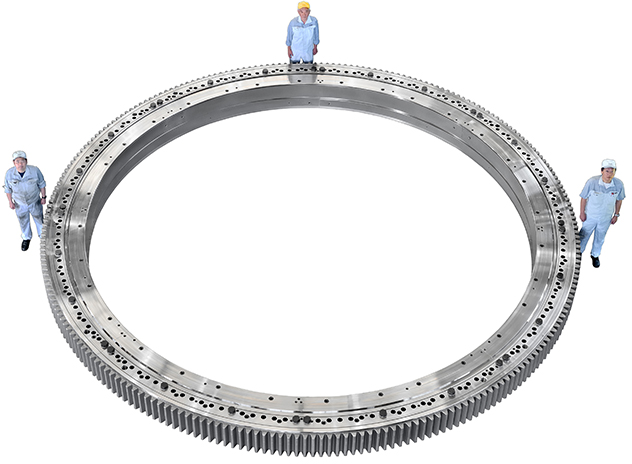

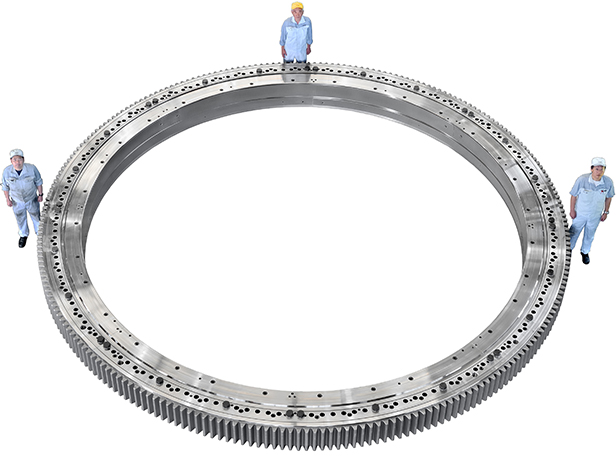

The diameter of the excavator to be used in the construction of the Tokyo Outer Ring Road tunnel was 16.1 m, exceeding the roughly 14-m diameter of the one used for the Tokyo Bay Aqua-Line. It was the largest such device in Japan.

In order to support the rotation of this massive cutter shield, we developed this product (a triple-row cylindrical roller bearing) with a diameter of 7.7 m.

But transporting such an enormous triple-row cylindrical roller bearing as is would be extremely difficult with the transportation infrastructure in Japan, which has narrow roads, so it is necessary to perform segmented design and reassemble the bearing on-site.

Furthermore, for the excavator that rotates the cutter section and tunnels forward, the triple-row cylindrical roller bearing used to support the rotation is a very important part, and has a dramatic effect on the excavator's performance, so a high level of precision is required. At the same time, the bearing must have high durability and reliability to see the construction work through to the end, as it can be very difficult to replace individual components.

JTEKT has more than 20 years of experience in segmented transportation of triple-row cylindrical roller bearings.

Thanks to this experience, we have been able to hone our special polishing technologies and various processing technologies such as distortion control during heat treatment, and these technologies allowed us to succeed in reducing the shift during rotation to a mere 0.1 mm, even when this massive bearing with a diameter of 7.7 m is assembled on-site from four separate parts.

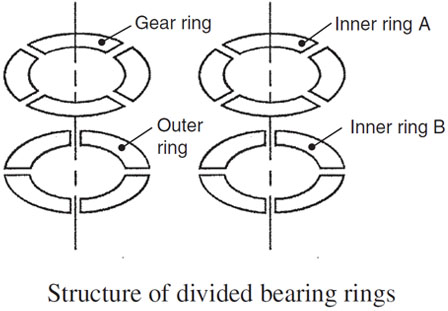

(1) The structure has four bearing rings: an outer ring, inner ring A, inner ring B, and a gear wheel that transmits digging torque. In order to transport them over land, each of the bearing rings was divided into four segments along a circumferential direction.

(2) The bolt-fastening and special design allow for the quartered bearing rings to be assembled as full rings at the tunneling site, while maintaining the same level of ring accuracy and gear accuracy as a non-segmented bearing.

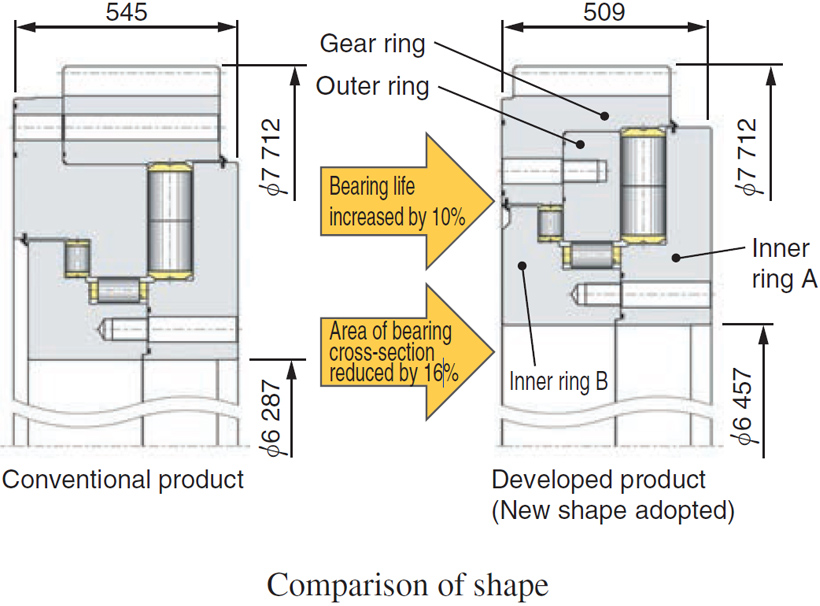

In order to fit the bearing into the limited space inside the excavator, as well as to meet the market demand for longer service life, we employed a new shape. Compared to previous shapes, without changing the outside diameter at the tooth tips, the bearing service life was able to be increased by 10%, and the bearing sectional area was decreased by 16%.

It is our hope that this development of a segmented triple-row cylindrical roller bearing that can be used in various places will continue to be in demand for the digging of tunnels for railway and road construction going forward.

JTEKT hopes to promote new product development and contribute to infrastructure maintenance both in Japan and beyond.

cylindrical roller bearing for a shield excavator

With a diameter of 7.7 m, this segmented triple-row cylindrical roller bearing is among the largest in Japan.

It is a product that we developed for the growing infrastructure maintenance business, which includes the digging of very deep tunnels in urban areas.

By employing segmented design, we were able to facilitate transportation while maintaining the same high level of precision and durability as a non-segmented bearing.

Advanced Development Office

In order to meet the requirements of our customer, we went through trial and error over and over again until we finally created this product.

Year after year, tunnel excavation projects are getting bigger, deeper, and longer, and so their difficulty level is also rising.

For this reason, our customers' required tunneling distance--in other words, the required bearing service life--has been increasing. What our customers need is products that can be used safely even after tunneling for a long time, not to mention products with greater load performance. What's more, because in Japan we have the Road Traffic Act, there is another condition that we need to design and manufacture the product in a disassembled state.

In order to meet these various demands, at an unprecedented size, we took about a year and a half, performing tests to confirm the cross-section shape, the machining process, and the procedures. By doing this, we optimized the various elements.

During the manufacturing stage, we ran into distortions that hadn't been predicted in the design stage, so things didn't go exactly as planned, but as a result of repeated trial and error, we were able to complete this segmented triple-row cylindrical roller bearing that was one of the largest in Japan, had a high degree of reliability, and met the requirements of our customer.

This product is the kind of technology that no company in Japan other than JTEKT could produce. This is truly one of the "No. 1 & Only One" products and services spoken of in our JTEKT Group Vision, and through the construction of infrastructure it will surely contribute to a prosperous society.