-

Problems

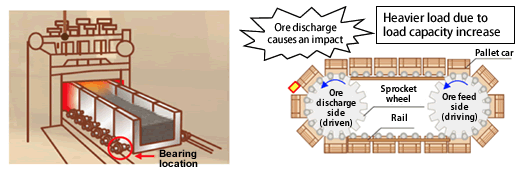

- Heavier applied load caused by the increased load capacity resulting from width expansion

- Increased impact load during ore discharge

- Damage on bearings due to the intrusion of foreign matter such as dust

- Difficulty in forming an oil film due to extremely low-speed rotation

-

Solutions and Results

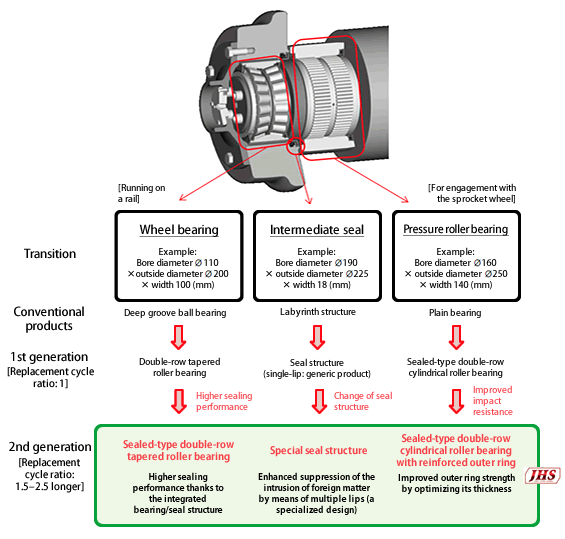

- Wheel bearing:

Higher sealing performance thanks to the integrated bearing/seal structure - Intermediate seal:

Enhanced suppression of the intrusion of foreign matter by means of multiple lips (a specialized design) - Pressure roller bearing:

Improved outer ring strength by optimizing its thickness

- Wheel bearing:

Achievements

- Pressure roller bearings prevent sudden fracture of the outer ring during operation (within the regular maintenance cycle).

- Wheel bearings reduce the intrusion of foreign matter into the bearing, thus improving the grease condition and improving the bearing service life..

Comments from Our Customers

- The pressure roller bearings reduce the number of occurrence sudden failure of the equipments compared to plain bearings, and contribute to stable operation.

- The wheel bearings and intermediate seals allow for a longer maintenance cycle.

A Message from JTEKT

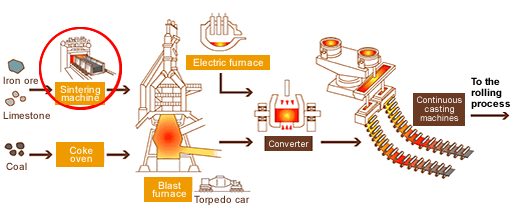

In all the equipment of steel production facilities (not just sintering equipment), damage to bearings results in decreased production and other significant losses.

The usage conditions are harsh, and we have proceeded with development with the goal of improving sealing performance and impact resistance, but we intend to strive for further improvements going forward.

Product

JHS (JTEKT Hyper Strong) Series for Use in Steel Production Equipment

For Pallet Cars in Sintering Equipment

- Sealed-type double-row tapered roller bearings for wheels

- Higher sealing performance thanks to the integrated bearing/seal structure

- Intermediate seal for wheels

- Enhanced suppression of the intrusion of foreign matter with multiple lips (a specialized design)

- Sealed-type double-row cylindrical roller bearings for pressure rollers

- Improved outer ring strength by optimizing its thickness

Contact Us