-

Problems

- With more and more autonomous driving of agricultural and construction vehicles, we want bearings that have greater robustness (resistance to being affected by external factors) than before, that do not get damaged easily, and last longer before needing to be overhauled.

-

Solutions

- Structural toughening through the optimization of material components and heat treatment conditions

- High hardness of race surface resulting from precipitation of fine precipitates

- Fatigue strength increasing through securing the appropriate volume fraction of retained austenite (retained γ)

Achievements

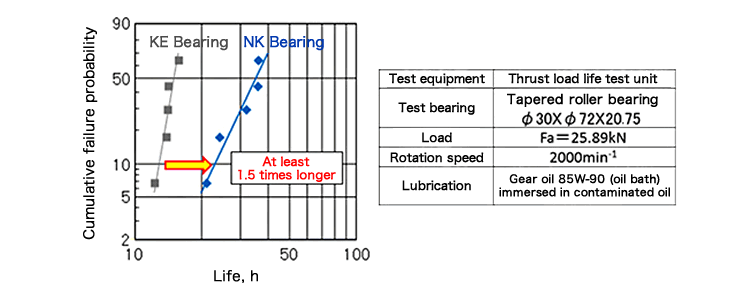

- Succeeded in achieving at least 1.5 times longer life for bearings in contaminated oil

(* Compared to JTEKT’s conventional product, the KE Bearing)

A Message from JTEKT

Longer service life and greater robustness thanks to materials and heat treatment based on a new concept

Bearings used under harsh conditions such as on agricultural and construction machinery are required to have high robustness, and as such, JTEKT has been continuously developing and launching long-life bearings (such as the KE bearing and SH bearing) on the market that satisfy the demand for high robustness. However, since the development of vehicles that require autonomous driving such as unmanned dump trucks and tractors is recently making progress in the agricultural and construction machinery industries, a bearing failure during the autonomous driving could be a severe problem. Furthermore, the demand for life cycle cost reduction and overhaul period extension are also increasing, so the expectations toward longer life and higher robustness are growing.

Therefore, JTEKT is proud to say that we have developed a bearing with longer service life that has accomplished both this longer service life and greater robustness thanks to materials and heat treatment based on a new concept.

(Construction and Industrial Machinery Group, Bearings for Industrial and Construction Devices Engineering Office, Industrial Machinery Application Engineering Dept.)

Product

An example of application: Tapered roller bearings

-

JTEKT Corporation has developed a next- generation long-life bearing (NK bearing) for use in harsh conditions mainly on agricultural and construction machinery. Through the optimization of material components and heat treatment conditions, we have succeeded in achieving further long life with improved robustness.

As such, JTEKT contributes to customers’ vehicle reliability improvement and maintenance manhour reduction, as well as the promotion of autonomous driving of agricultural and construction machinery and other machinery/vehicles

* “NK” is an abbreviation of “New (A)dvanced Knowledge”

Contact Us