Each component of an engine has different operating environments and performance requirements. In the same way, bearings are also required to have many features, including vibration-resistance, high-speed rotation, high-temperature resistance and high-environmental resistance. JTEKT provides a wide variety of bearings developed leveraging technologies accumulated hand-in-hand with advancements in the automotive industry.

In recent years, a demand has emerged to respond to global needs, including extremely cold regions, and achieve better fuel efficiency, weight and size reduction assuming use in the ultra-low temperature of minus 40 degrees Celsius.

- Related product types:

Used as a mechanism to transmit the camshaft motion to the intake/exhaust valve.

The fatigue strength of the transfer surface is improved through special surface treatment to minimize damage to counterpart components.

- Related product types:

Used in the variable valve mechanism for realizing efficient suction and exhaust flows.

- Related product types:

The balance shaft used in a poor lubrication environment is supported with a small amount of torque in order to improve the reliability of balance shaft movement.

- Related product types:

The idler pulley is used for layout of auxiliary machine belts and tension adjustment.

It can adapt to road conditions and severe weather conditions, and offers the features of high-speed rotation, high heat-resistance and water resistance.

- Related product types:

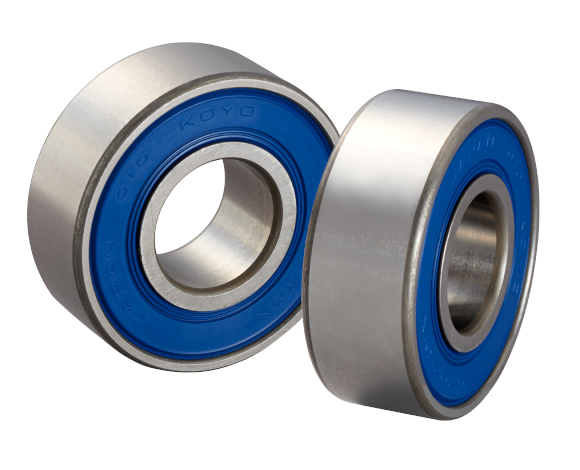

These bearings require high sealing performance due to being used inside water pumps.

A highly reliable air tight seal is adopted, which substantially improves sealing performance and achieving a long service life.

- Related product types:

A long service life in high-temperature, high-speed rotation environments is demanded of bearings used in alternators.

Grease with improved vibration resistance was developed and adopted to realize a long service life.

- Related product types:

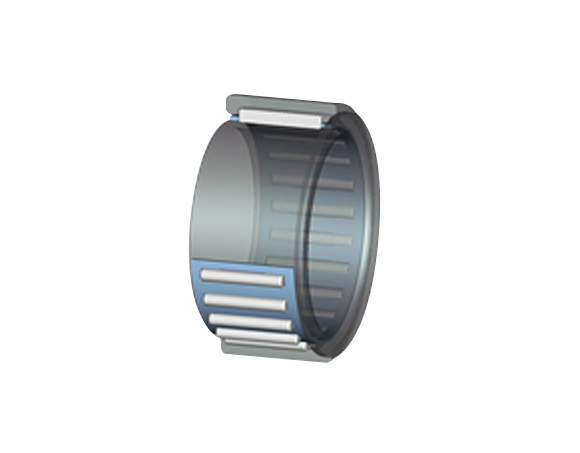

While the belts of auxiliary machines are susceptible to slip and flutter due to variation in the engine speed, an alternator pulley with a built-in one-way clutch can suppress belt flutter.

- Related product types:

Used in the part supporting rotation of the compressor pulley of the air conditioner.

Offers water resistance under severe water splashes and low-torque performance.

- Related product types:

The bearings in the compression mechanism of compressors are submerged in refrigerant. As such, the bearings need to operate in diluted lubrication. JTEKT, however, has developed highly durable, low-torque bearings capable of operating in diluted lubrication as a result of improvements to design specifications.

- Related product types:

Bearings adopting an ultra-long-life ceramic ball bearing with excellent ultra high-speed, high-temperature and resistance to foreign matter. With ceramic balls and a heat-resistant raceway and retainer, both high-temperature resistance and high-speed characteristics are realized.

- Related product types:

Various oil seals are used in the engine and peripheral components to assist smooth bearing operation.