Bearings for use in special environments such as clean, vacuum, high-temperature and corrosive environments, are required to have special properties, such as non-magnetic, insulating and high-speed.

For this reason, regular bearings made from bearing steel and lubricant such as oil and grease cannot be used.

JTEKT's special environment EXSEV (short for EXtreme Special EnVironment) series meets these requirements.

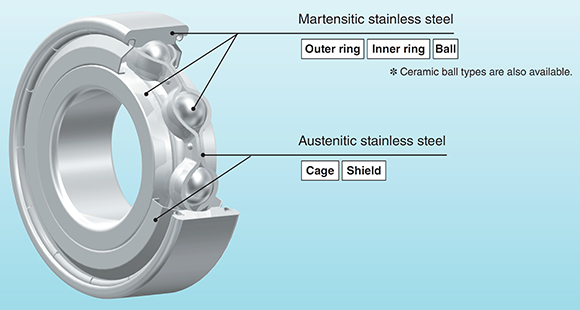

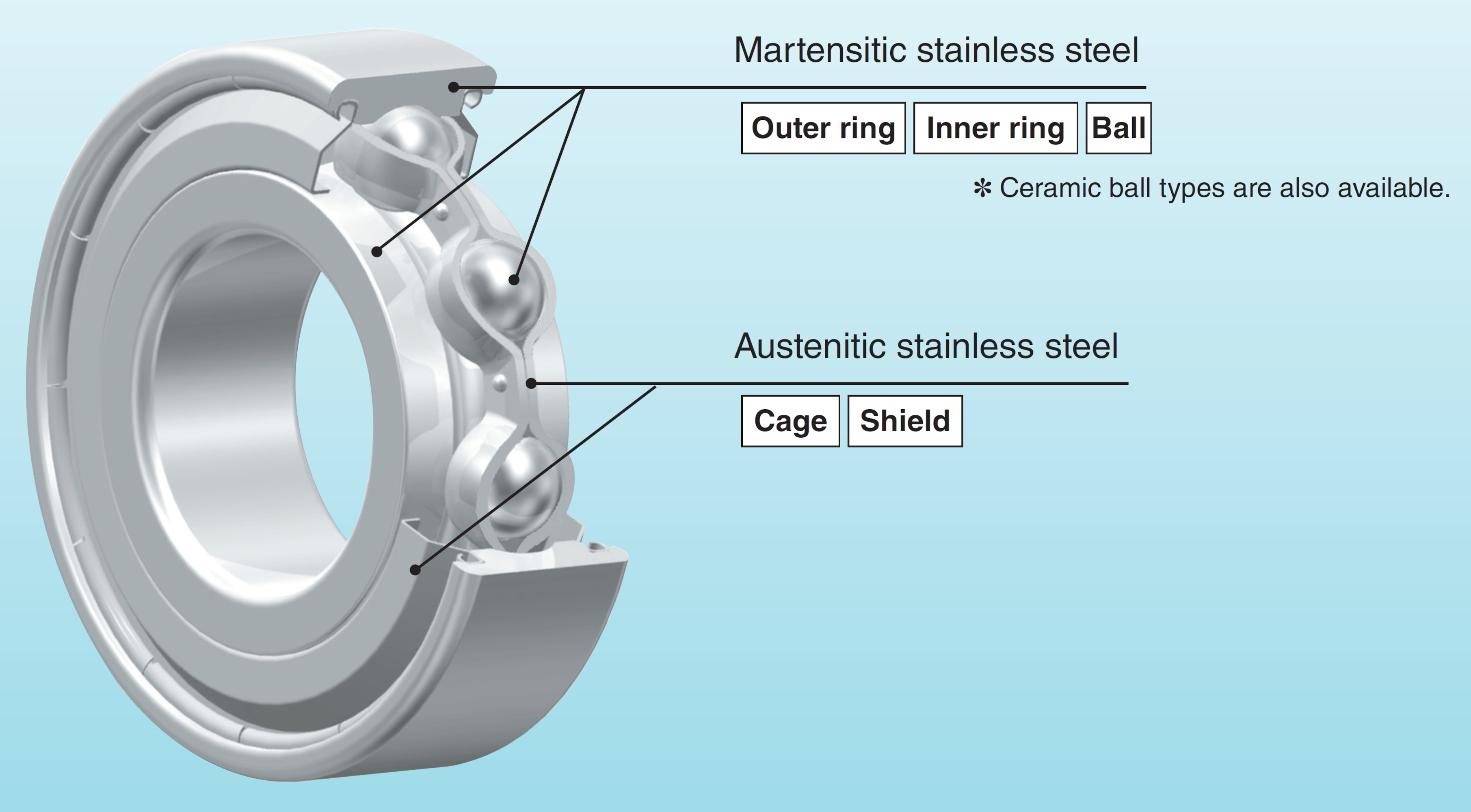

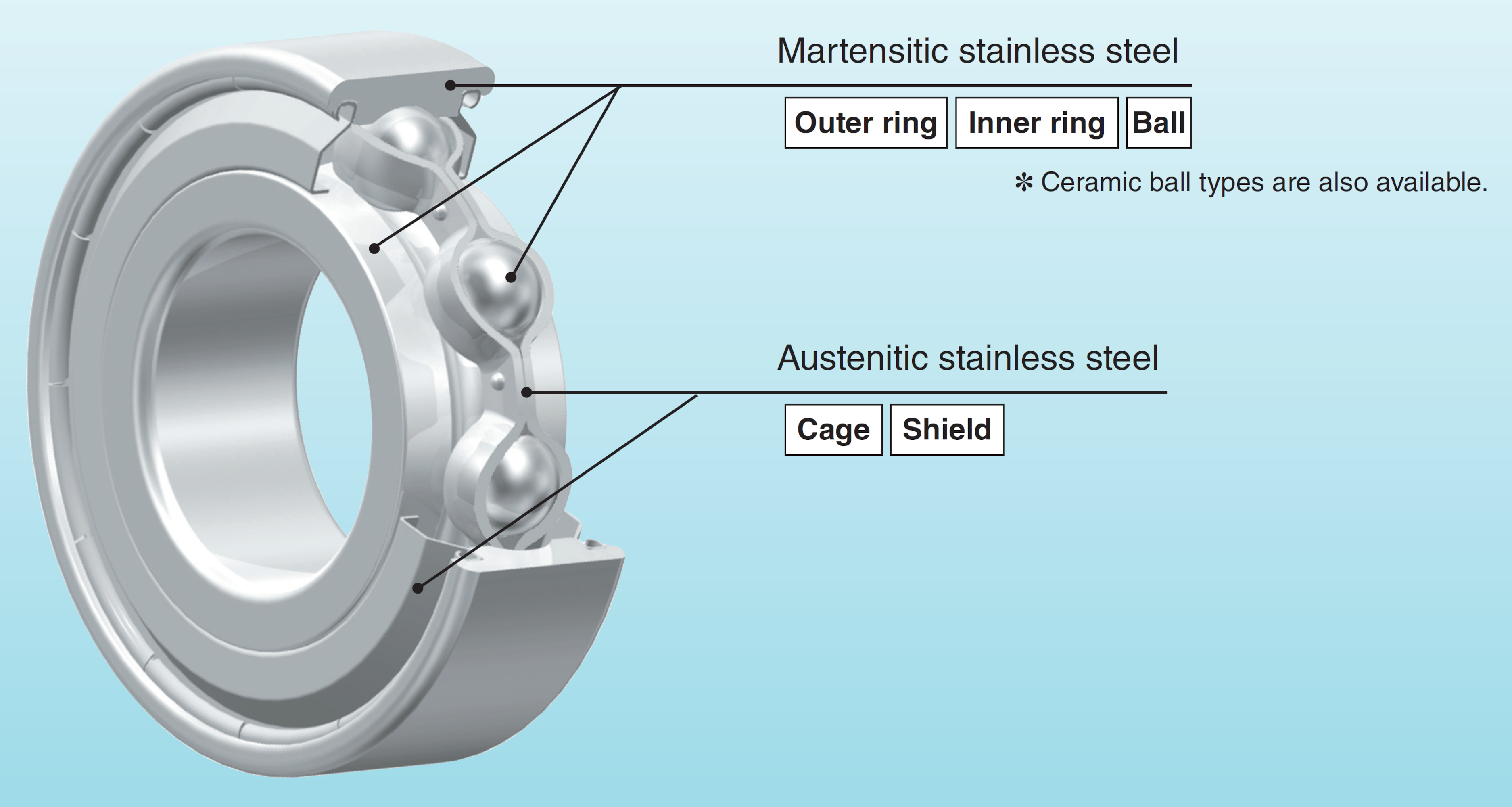

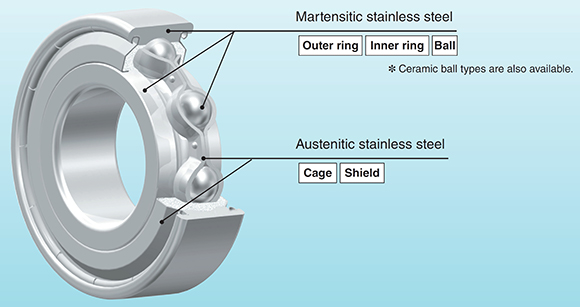

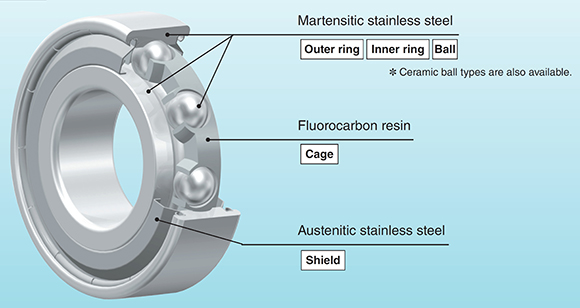

Stainless is the standard bearing material, however we offer an abundant variety of bearings to suit any given application.

Bearing varieties include corrosion-resistant stainless steel, ceramic, high-speed tool steel, as well as bearings which use solid lubricants such as high-molecular fluorine and molybdenum disulfide coatings, resin or soft metal.

- Clean

- Vacuum

This bearing has a fluoropolymer gel coating on its rolling surfaces as the lubricant.

- Applications:

- Semiconductor manufacturing equipment, Transfer systems, Lithography equipment, Vacuum motors, Vacuum equipment

- Clean

- Vacuum

- High-temperature

This bearing has a fluoropolymer coating on its rolling surface as the lubricant.

- Applications:

- Semiconductor manufacturing equipment, LCD manufacturing equipment, Transfer systems, Vacuum equipment, Sputtering equipment

- Clean

- Vacuum

This bearing is lubricated with a fluoropolymer coating over the entire surface of all bearing components.

- Applications:

- Semiconductor manufacturing equipment, LCD manufacturing equipment, Vacuum equipment, Lithography equipment, Sputtering equipment, Vacuum motors

- Clean

- Vacuum

- High-temperature

This bearing is lubricated with the packed fluorinated EXSEV®-EX (Grease), which is suitable for use in clean environments and vacuum environments.

Compliant with environmental regulations (does not contain PFOA)

- Applications:

- Semiconductor manufacturing equipment, LCD manufacturing equipment, Transfer robots, Vacuum pumps

- Clean

- Vacuum

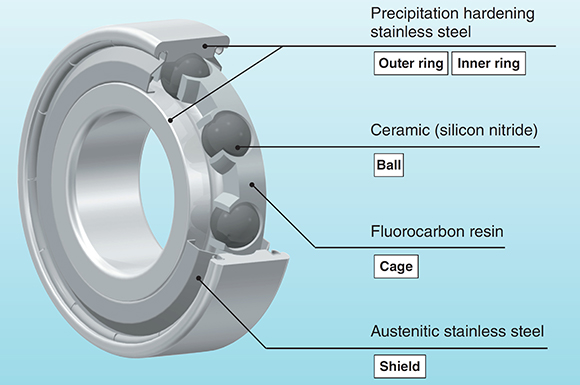

This bearing is lubricated with a solid fluoropolymer lubricant,which offers superior lubrication performance. The cage is made from a low-particle-emission fluorocarbon resin.

- Applications:

- Semiconductor manufacturing equipment, LCD manufacturing equipment, Transfer systems, Inspection systems

- Clean

- Magnetic field

- Vacuum

- Electric field

- Corrosive

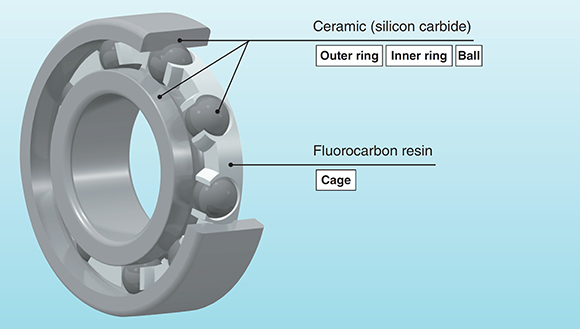

This bearing uses a silicon carbide ceramic material, which is resistant to strong acids and alkalis.

- Applications:

- Aluminum electrolytic capacitor manufacturing equipment

- Clean

- Magnetic field

- Vacuum

- Electric field

- Corrosive

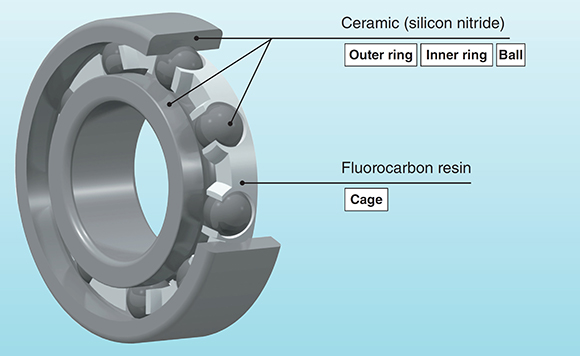

This bearing has its components made of silicon nitride ceramic and uses fluoropolymer as the lubricant. It is typically used in vacuum and corrosive environments.

- Applications:

- Semiconductor manufacturing equipment, LCD manufacturing equipment, Semiconductor inspection equipment, Synthetic fiber manufacturing equipment, Canning machinery, Ultrasonic motors

- Magnetic field

- Vacuum

- Electric field

- Corrosive

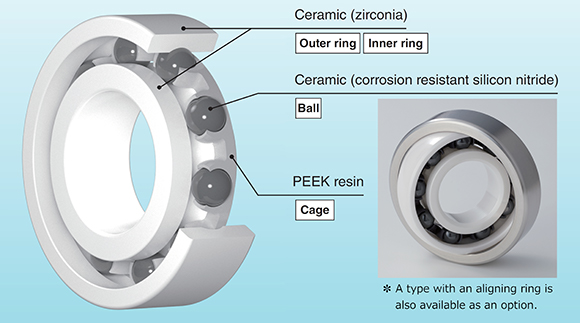

This bearing uses ceramic (zirconia) for its material and is lubricated with the solid lubricant of the molded PEEK resin cage. It can be used in corrosive liquids or water and also has excellent impact resistance.

- Applications:

- High-performance film manufacturing equipment, Cleaning equipment

- Clean

- Vacuum

- Electric field

- Corrosive

This bearing uses a stainless steel variety that has excellent corrosion resistance. As the lubricant, fluoropolymer is used. It is compatible with underwater use.

- Applications:

- Semiconductor manufacturing equipment, Chemical manufacturing equipment, Food machinery, Cleaning equipment

- Corrosive

This bearing has its components made of stainless steel, and is lubricated with lithium containing EXSEV®-KHD (Grease), which is packed in adequate amounts. This bearing is suitable for use in slightly corrosive environments.

- Applications:

- Chemical equipment, Transfer systems

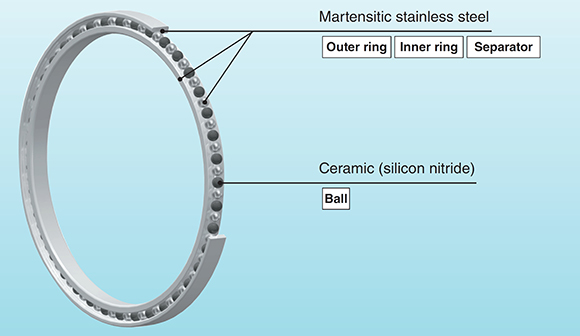

- Magnetic field

- Vacuum

- Electric field

- High-temperature

- Corrosive

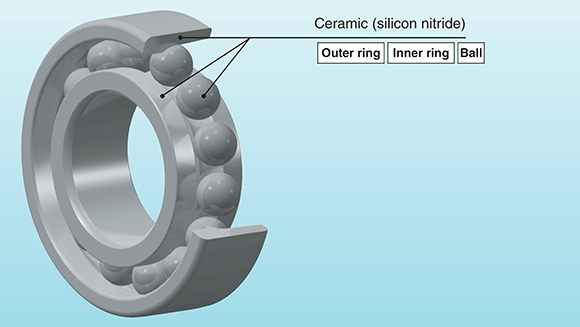

This bearing has all components made of ceramic for use in an ultrahigh temperature environments. No cage is provided. Being an angular contact ball bearing, this bearing is normally used in pairs.

- Applications:

- Baking furnace cars, Fans in furnaces

- Vacuum

- High-temperature

The bearings are filled with fluorinated grease capable of handling high temperatures even up to 350˚C.

- Applications:

- Semiconductor manufacturing equipment, LCD manufacturing equipment, Transfer robots, Vacuum pumps

- Vacuum

- High-temperature

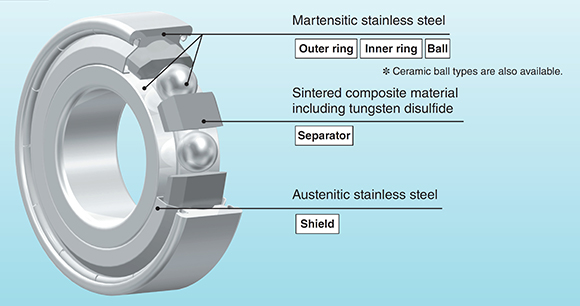

This bearing has extremely heat resistant tungsten disulfide included in the separator material as the lubricant.

- Applications:

- Semiconductor manufacturing equipment, LCD manufacturing equipment, Vacuum evaporatior, Plasma display panel manufacturing equipment

* We recommend that this bearing is used with horizontal axes. For information on using this bearing with items other than horizontal axes, consult JTEKT.

- Vacuum

- High-temperature

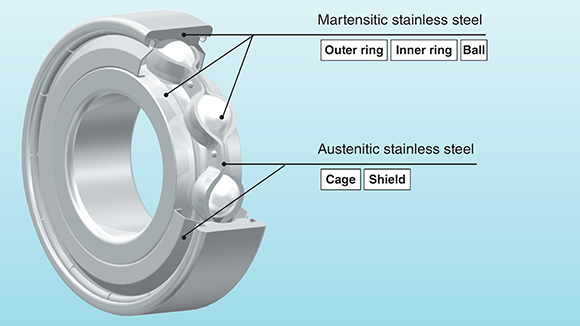

This bearing has silver ion plated on the stainless steel balls, as the lubricant.

- Applications:

- Semiconductor manufacturing equipment, LCD manufacturing equipment, Vacuum evaporator, Medical equipment, Vacuum motors

- Vacuum

- High-temperature

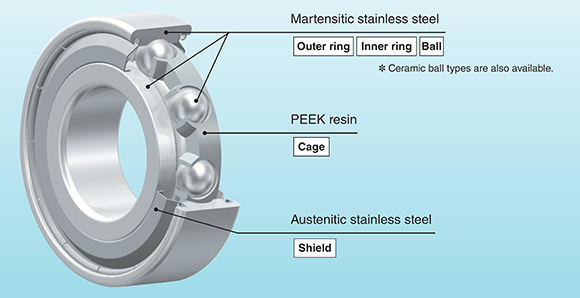

This bearing has a highly heat resistant solid lubricant, such as molybdenum disulfide included in the cage material.

- Applications:

- Carton manufacturing equipment, LCD cleaning equipment

- Vacuum

- High-temperature

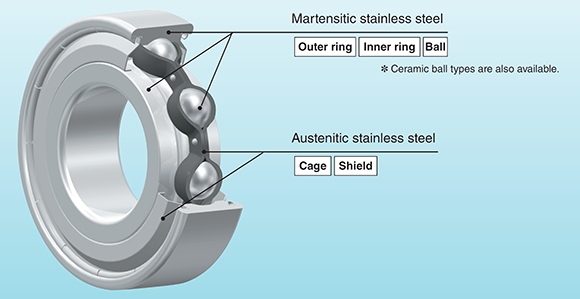

This bearing has molybdenum disulfide baked on the surface of the stainless steel cage, as the lubricant.

- Applications:

- Semiconductor manufacturing equipment, LCD manufacturing equipment, Vacuum evaporator, Turbo molecular pump, Rotary furnaces

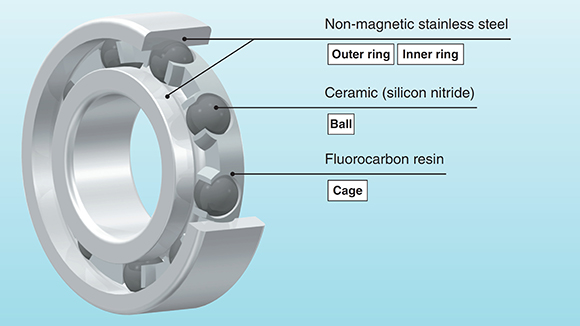

- Clean

- Magnetic field

- Vacuum

- Electric field

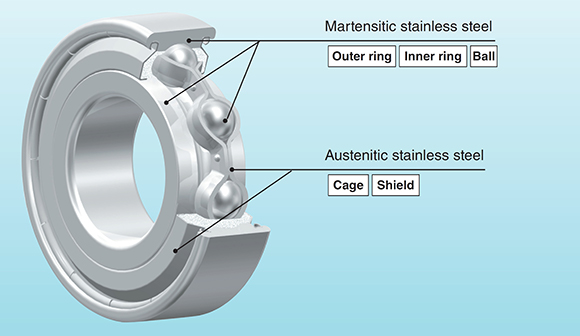

This bearing uses non-magnetic stainless steel. It includes fluoropolymer as the lubricant. This bearing can be used in a vacuum environment.

- Applications:

- Semiconductor manufacturing equipment, Semiconductor inspection equipment, Canning machinery, Superconductivity-related equipment, Welder

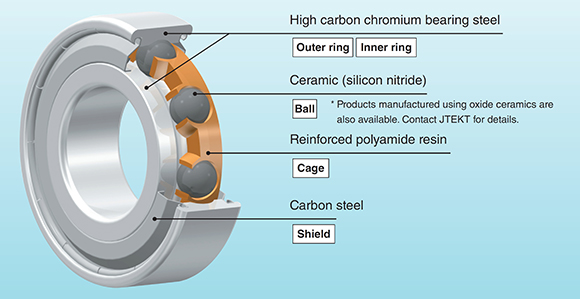

- Electric field

- High speed

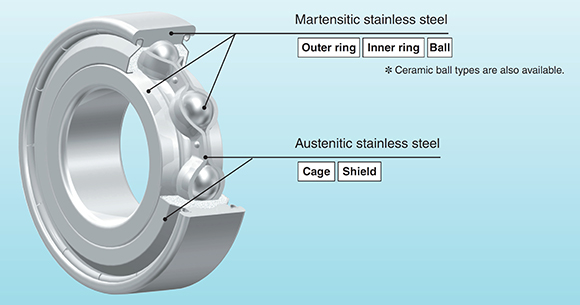

This bearing is a standard hybrid ceramic bearing. Lubricated with grease or oil, it can be used as an insulating bearing or high speed bearing.

- Applications:

- High speed stranding machine guide rollers, Motors, Generators

This bearing is based on the K series super thin section ball bearing, which is widely used in industrial robots. Provided with some adaptations, this bearing is compatible with clean or vacuum environments. It uses fluorinated EXSEV®-EX (Grease) as the standard lubricant. However, please consult with us regarding New Clean Pro Bearing-PR and other solid lubricants.

- Applications:

- Wafer transfer robot, Semiconductor manufacturing equipment, LCD manufacturing equipment

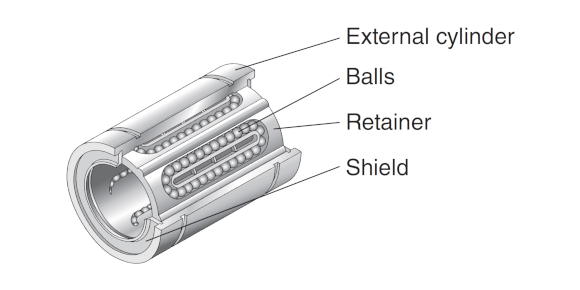

The linear motion ball bearings are a high precision product that moves linearly in axial directions while having rolling contact with the shaft. Having balls, retainer and shields housed in an external cylinder, this compact bearing moves linearly without limit to the stroke distance.

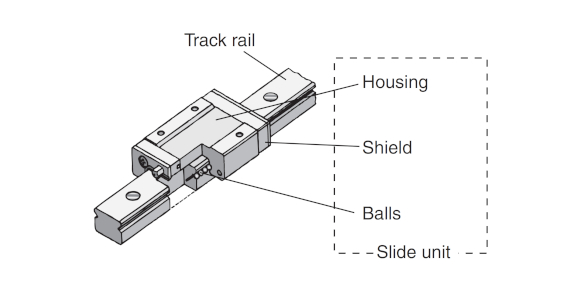

The Linear Way Bearing Units have a slide unit in which balls circulate, allowing the slide unit to move linearly on the track rail without limit. High precision linear motion can be obtained easily by fixing the slide unit and track rail with bolts.

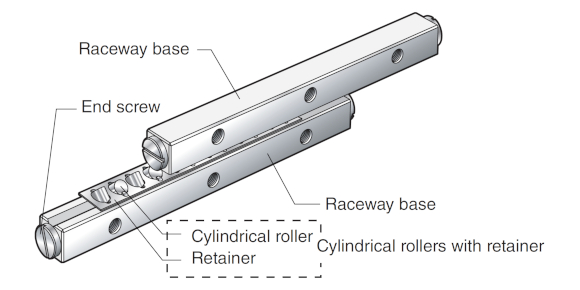

The Cross Roller Way Bearing Unit is a linear motion bearing unit consisting of two raceway bases. Each base has one longitudinal plane cut into a V shape, which serves as the rolling surface. Two bases are in contact on each of the other's V-cut surface, and cylindrical rollers with a retainer are placed between the surfaces. Any pair of adjacent cylindrical rollers is directed at right angles to each other, thus enabling smooth and extremely accurate linear motion.

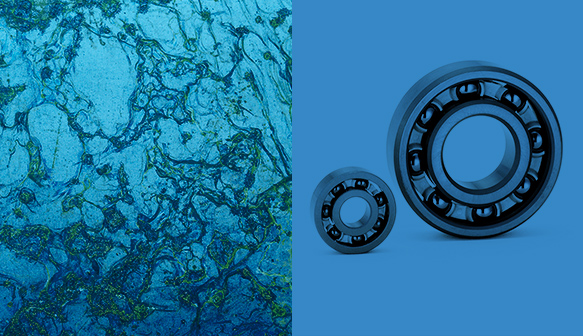

JTEKT also supplies Ceramic Balls (silicon nitride), which have excellent resistance to wear and seizure, and are usable in corrosive environments and ultrahigh vacuums. Other major features of these balls are excellent heat resistance (up to 800˚C), high rigidity, lightweight (40% compared to bearing steel), non-magnetic, and have insulating characteristics.

The Ceramic Balls are useful in many applications such as jigs, tools, gauges, solenoid valves, check valves, other valve varieties, high grade bicycle parts, automotive parts, and machine components.

This fluorinated grease is designed for vacuum environments with low particle generation. It is also compliant with environmental regulations (does not contain PFOA).

EXSEV®-EX offers superior performance for rolling bearings, linear motion bearings, and ball screws. JTEKT also handles requests for grease only. Contact us for more information.

Reliable, corrosion-resistant and suitable for use in solutions