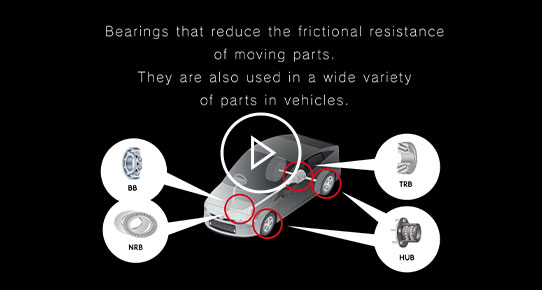

Bearings for alternators

Achieving Longer Service Life at High Temperatures, Low-Friction Torque, and Light weight

An alternator is a device that generates alternating current, rectifies it with a diode, and outputs it. JTEKT's bearings have a long service life even under high-speed rotation and high-temperature conditions, and their low-friction torque and light weight help to lower fuel consumption, while also contributing to the miniaturization of alternators with their improved materials.

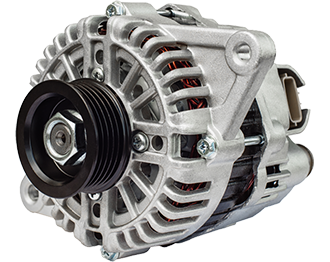

Alternator Structure

With the increase in the amount of electricity consumed by electrical and electronic devices installed in cars, there has been a wider spread in small-type alternators that rotate at high speeds with increased power generation capacity compared to how it used to be.

What Are Alternator Bearings?

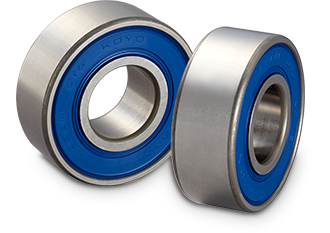

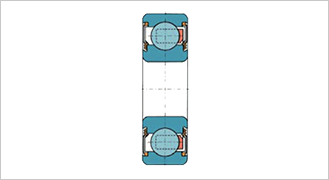

Structure

Sealed-type deep groove ball bearings are used to support the rotor.

Features

- 1.They use materials and grease that increase durability under high-speed rotation, high-temperature, and high-vibration conditions.

- 2.They use low-torque seals with excellent grease leakage prevention and dust resistance.

- 3.If the temperature conditions are severe, we can also provide heat-resistant (180°C) bearings.

What Are Clutch Pulleys for Alternators?

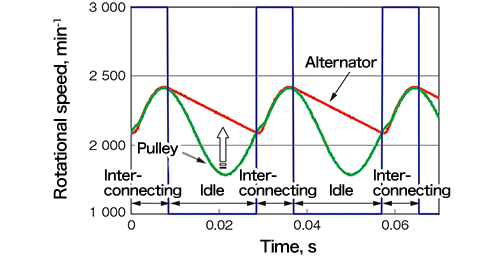

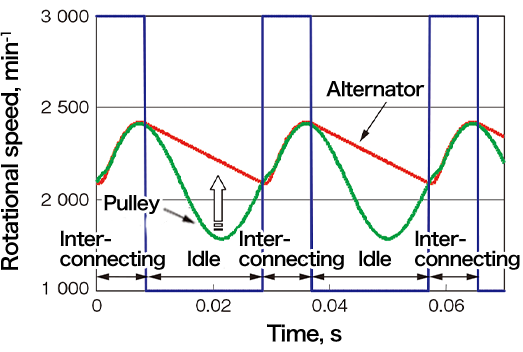

These have a built-in one-way clutch and absorb fluctuations in belt tension in the drive pulley of the alternator, preventing the clattering and squeaking of the auxiliary belt and contributing to the extension of the belt service life.

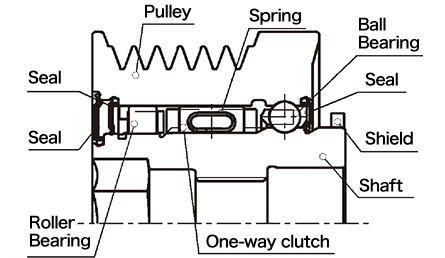

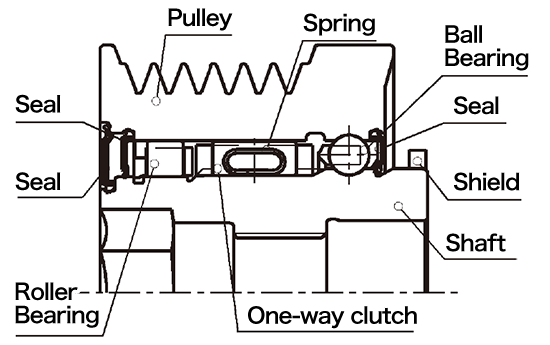

Structure

A one-way clutch is built into the alternator pulley.

Features

- 1.By using grease whose friction coefficient does not change easily from low temperature to high temperature, optimizing the internal design, and precision machining, the variation is reduced, while the engagement performance of the one-way clutch is improved.

- 2.Ball bearings prevent temperature rise due to axial load, and grease with excellent heat resistance is used to improve durability.