Tensioner and Idler Bearings

Achieving Longer Service Life in

High-Speed Rotation and High

Temperatures

These are used in the timing belt and auxiliary drive belt to adjust the belt tension or change the belt running path. JTEKT's bearings have a long service life even under high-speed rotation and high-temperature conditions, and their high-strength resin pulleys help to reduce the weight.

Functions Required

of Bearings and

the Belt Mechanism

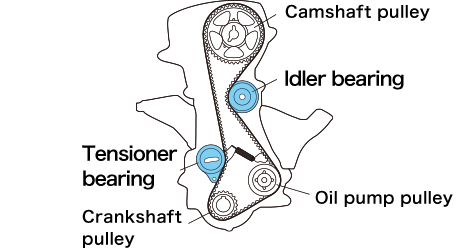

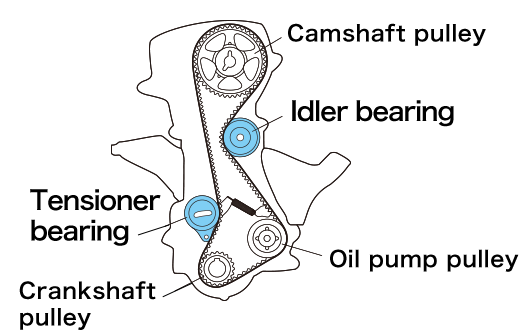

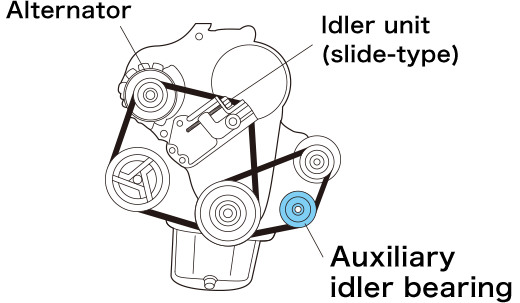

A car's engine includes both:

- • a timing belt mechanism that drives the camshaft, oil pump, etc.; and

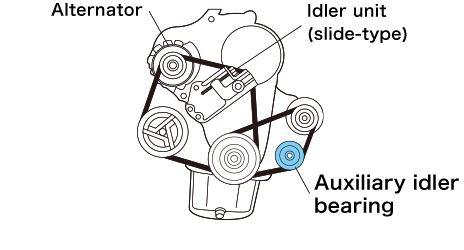

- • an auxiliary drive belt mechanism that drives the auxiliary machines such as the alternator, air conditioner, and water pump.

Timing belt mechanism

Auxiliary belt mechanism

Because the bearings are mounted on the engine, they have to be reliable in high-speed rotation and high temperatures.

Tensioner and Idler Bearings

The timing and auxiliary belts are equipped with idler bearings with pulleys and brackets attached to them.

Of these, in the timing belt mechanism, the type with a slotted hole in the inner ring or a bracket for tension adjustment is sometimes called the "tensioner bearing," and the type without an adjustment mechanism is sometimes called the "idler bearing."

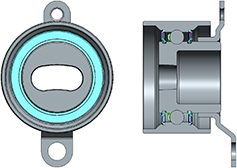

Auxiliary idler bearings are also used in auxiliary drive belt mechanisms.

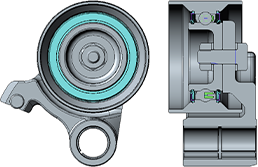

Tensioner bearing

(for adjustment)

Idler bearing

(for fixing in place)

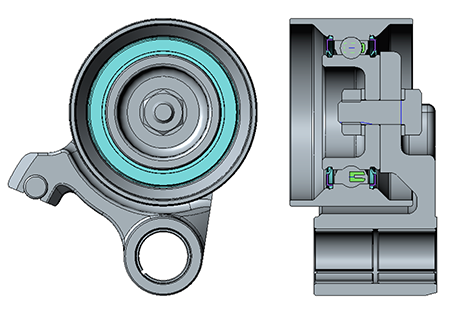

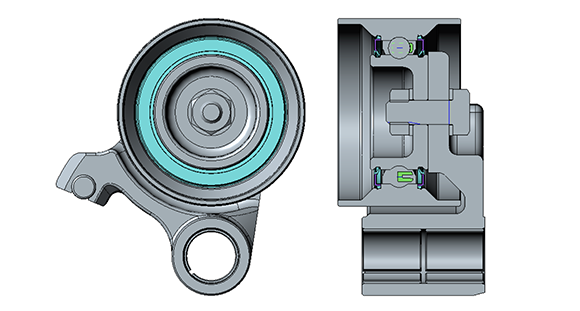

Structure

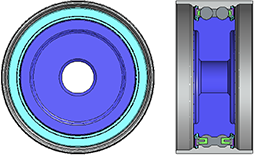

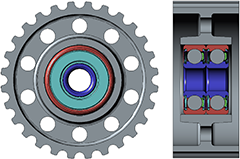

Sealed-type deep groove ball bearings are used, and the idler pulley and mounting bracket are of dimensions and shapes suited to the type of engine. There are several types, such as a pulley-integrated type and a toothed type, and some of them are significantly lighter with reinforced resin pulleys (see below for some examples of the types).

Features

- 1.By using materials such as seal and grease that work under high-speed rotation and high-temperature conditions, they improve reliability.

- 2.By adapting them to severe driving environments and severe weather conditions, they improve the anti-penetration potential against muddy water and dust.

- 3.A reinforced resin pulley with excellent heat resistance and chemical resistance is used to significantly reduce the weight.

What Are Hydraulic

Auto Tensioner

Bearings?

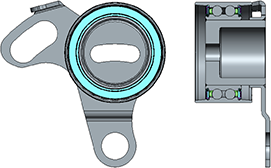

In each tensioner bearing, a slotted hole in the inner ring or a bracket is used to bolt it together, and the initial tension of the belt is adjusted.

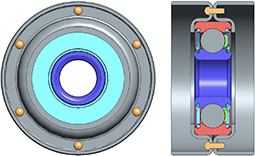

However, the auto tensioner automatically adjusts to the appropriate belt tension due to the effect of the hydraulic damper even after assembly.

JTEKT is contributing to improved reliability by providing hydraulic auto tensioner bearings.

Structure

A sealed deep groove ball bearing is used, a bush is provided in the swing center of the bracket, and the contact part with the hydraulic damper is made to have high hardness.

Features

- 1.By using materials such as seal and grease that work under high-speed rotation and high-temperature conditions, they improve reliability.

- 2.By adapting them to severe driving environments and severe weather conditions, they improve the anti-penetration potential against muddy water and dust.

Example: Types of Tensioner and Idler Bearings

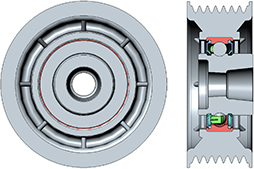

Idler bearings

-

Pulley-separated type

-

Pulley-integrated type

-

Toothed type

Tensioner bearings

-

Bracket type example 1

-

Bracket type example 2

-

Hydraulic auto tensioner

Auxiliary idler bearings

-

Resin pulley type

Replacing Tensioner

and Idler Bearings

Bearing replacement in the timing mechanism is often done at the same time as replacing the timing belt, and it is recommended that replacement be performed after around 5 years or 100,000 km.

But, because it depends on the car model and condition, please contact your car's manufacturer to know when to do the replacement.

In addition, when replacing the timing belt, other components around the engine, such as the water pump and oil seal, are usually replaced at the same time.