Hub units for passenger vehicles

High Accuracy Improving Durability on Rough Roads

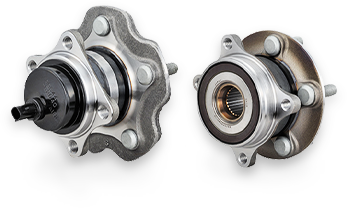

The hub unit is a device that fills an important role in supporting a car by the wheels, and integrates the bearings and the surrounding components. There is one type of hub unit that rotates smoothly while supporting the vehicle weight, and another type that transmits the driving force from the engine to the wheel. Because the hub unit has a large effect on vehicle performance, it is required to have both durability on rough roads and a high degree of accuracy.

Functions Required

of Bearings and

the Wheel Structure

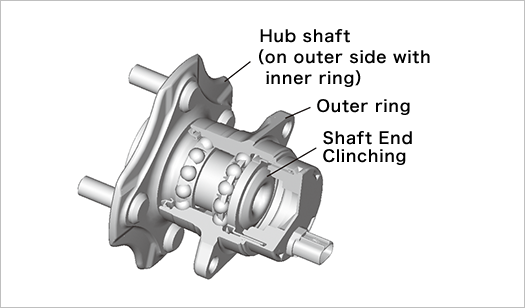

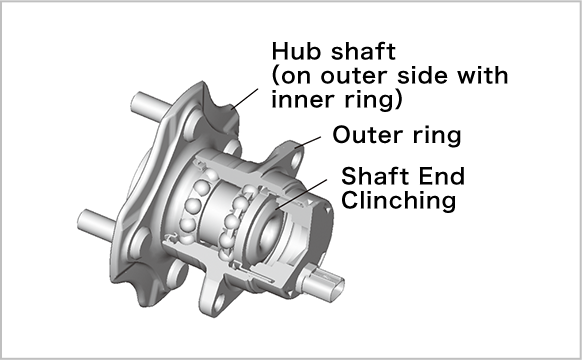

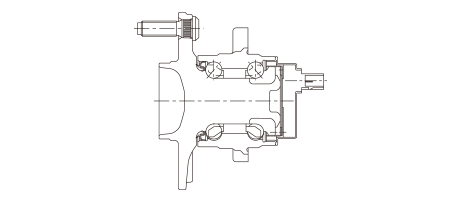

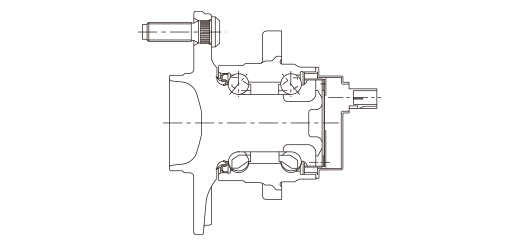

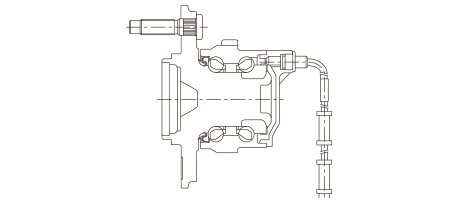

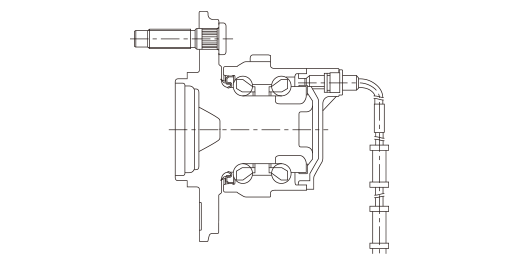

This image shows the whole structure of the axle component including wheel bearings. Wheels are either driving wheels (which rotate while supporting the vehicle weight and transmitting the driving force from the engine to wheel) or driven wheels (which rotate smoothly while supporting the vehicle weight). In the driving wheels, the bearings' inner rings rotate, while in the driven wheels, either the inner rings or the outer rings rotate.

What Are Hub Units

(Wheel Bearings)?

Structure

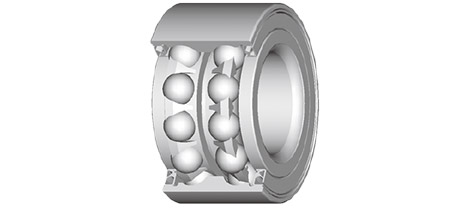

In the past, wheels on cars used a combination of two radial ball bearings or tapered roller bearings. With the increasing integration of the wheel bearing and the surrounding components, we have now reached a point where the "3rd generation" of hub units have been put into practical use.

• 1st-generation hub unit

The outer rings of two single-row bearings are integrated with each other, the unit is greased and sealed. There are two types: DAC, which uses balls, and DU, which uses tapered rollers.

DAC type

DU type

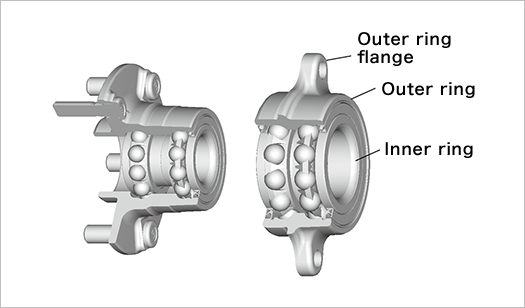

• 2nd-generation hub units

The outer ring of the 1st-generation hub unit is integrated with the flange. These hub units are divided into two types based on which of their rings rotates. In the outer ring rotation type, the wheel is attached directly to the outer ring; this type is only used for the driven wheels. In the inner ring rotation type, the hub shaft is attached to the inner ring; this type is used for both the driving wheels and the driven wheels.

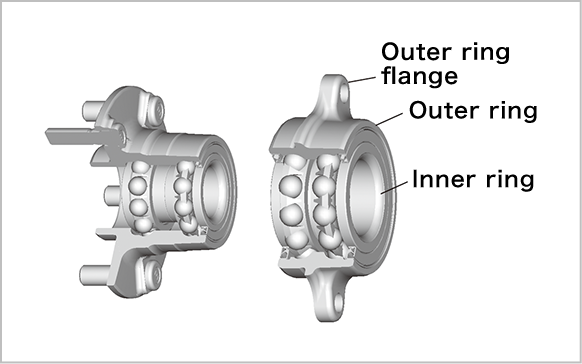

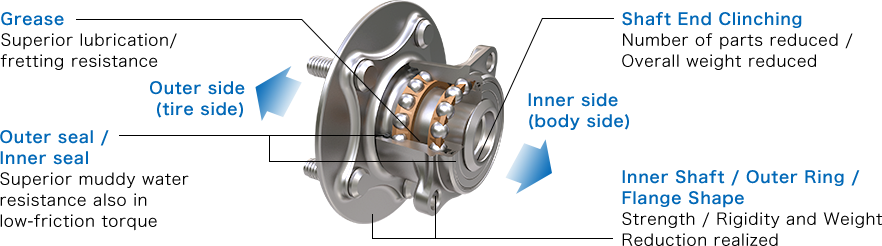

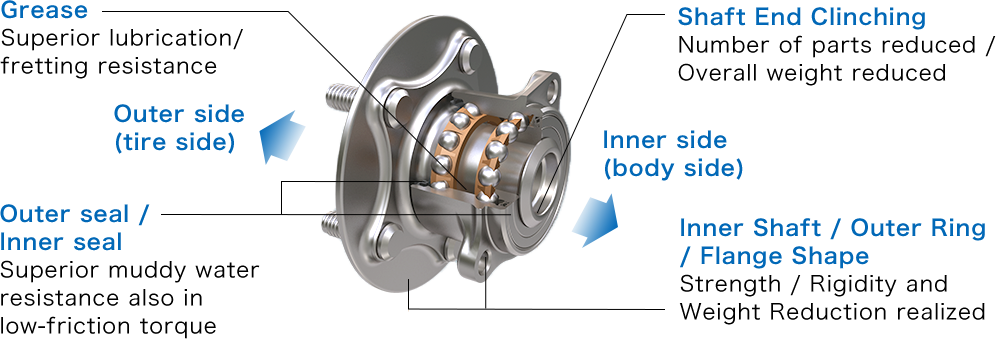

• 3rd-generation hub unit

This is a further development on the 2nd-generation hub unit. These hub units have an integration of the hub shaft and inner ring on the outer side (tire side) of the inner ring rotation type, and the number of 3rd-generation hub units with built-in high-performance sensors is growing. For driven wheels, the method of fastening the hub shaft and inner ring with nuts has been changed to the "shaft end clinching" method.

• Built-in ABS sensors

In order to improve car safety, the installation of an ABS (anti-lock brake system) that controls the brakes has become widespread, and hub units with built-in sensors equipped with a wheel rotation system have been used to reduce the size and weight, in addition to the process being simplified.

Integrated sensor cover

Built-in stick-type sensor

Features

The hub unit is required to have "both lower fuel consumption and superior driving performance," "high reliability," and "high capacity," and these are incorporated into each component.

- • Achieving both lower fuel consumption and superior driving performance, where lower fuel consumption means a reduction in weight and superior driving performance means both strength and rigidity at a high level

- • High reliability, even in severe environments such as driving on muddy roads, is ensured

- • The high-capacity bearing design is enabled by maximizing the use of allowable space

The following diagram shows the features of a hub unit for a driving wheel.

The seals are among the most important components supporting hub unit function and their techinical performance continues to increase in keeping with the evolution of the hub unit. JTEKT's seals ensure low friction torgue and superior muddy water resistance, and they also use a low friction torque seal to contribute to lower fuel consumption.

| Outer side (tire side) Outer seal |

Inner side (body side) Inner seal |

|

|---|---|---|

| Standard product |

|

|

| Low-torque spec. product |

|

|

Hub units for passenger vehicles

With passenger vehicles, the 3rd-generation hub units have been put into practical use.

Lots of vehicles use hub units with balls (ball hub units), but some heavy vehicles (SUVs and the like) use hub units that incorporate high-capacity tapered rollers (roller hub units).

Wheel bearings for commercial vehicles

With heavy commercial vehicles, the predominant arrangement continues even today to be combining two tapered roller bearings. By improving the bearing materials and heat treatment, JTEKT is achieving greater reliability for wheel bearings. The DU 1st-generation hub unit, equipped with a tapered roller, is also used.

When replacing the bearings, you should also replace the oil seals for the wheels.

Oil seals for wheels on commercial vehicles and trailers

When replacing the bearings, you should also replace the oil seals for the wheels.

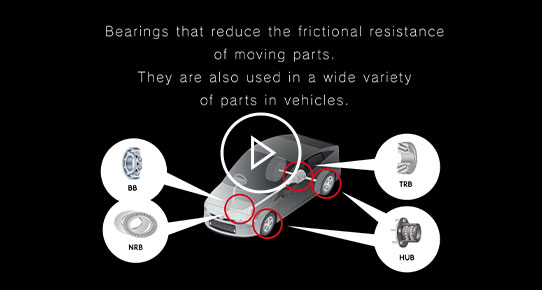

List of product videos

Replacement procedure of taper roller bearing for wheel hub

Low-Friction Torque Hub Unit

* LFT is an abbreviation for Low-Friction Torque and JTEKT's registered trademark.

JTEKT’s Strengths

JTEKT is developing products based on high-precision evaluation and analysis,

and manufacturing and marketing them based on a philosophy of meticulous quality control.

For Those Who Want

to Buy a Car Repair Product:

If you are looking for a product for car repair, or if you want to make a specific transaction with us,

please contact one of JTEKT’s sales agents.

Click here for more details about Car Parts search system.

Problems or Requests Relating to Car

Repair Products

At JTEKT, we support our customers when they have problems regarding the purchase of car repair products or specification considerations.

Feel free to let JTEKT know about your problems and requests,

whether it’s how to deal with breakdowns or other troubles, or switching over from another company’s product.

Outer side (tire side)

Outer seal

Inner side (body side)

Inner seal