Bearing Trivia

The Applications of Bearings I: This is how bearings are used in cars

- #1 What Are Bearings?

There are various types of bearings, each with their own strengths. Do you know what kinds of machines use what kinds of bearings?

In this part, we will introduce the bearings used in cars, as "Part I" of our introduction of the applications of bearings.

1. How are bearings used in a car?

In order to increase a car's performance by, for example, decreasing the CO2 (carbon dioxide) emissions that cause global warming, or reducing the number of breakdowns, bearings becomes more and more important.

In Part 1, we introduced the idea that, in the majority of cars using conventional engines, there are usually around 100-150 bearings at work.

Part 1: What Are Bearings? Let's learn about the basic functions of bearings!

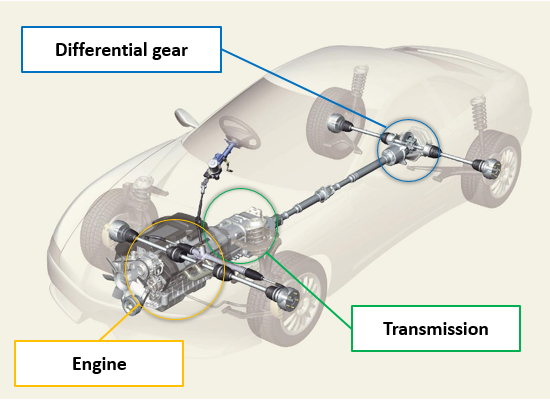

In this part, we will explain how bearings are used in the transmission and differential gear that transfer power from the engine to the wheels.

Fig. 1: The system that transfers driving force from the engine to the wheels

Fig. 1: The system that transfers driving force from the engine to the wheels

2. Bearings used in the transmission

Sometimes we want to drive faster, or we need a large amount of driving force such as when driving uphill. It is necessary to achieve a driving force appropriate for the driving circumstances.

The transmission is a device that converts the power from the engine into driving force and transmits it to the wheels. Inside, many different types of bearings are working together, each utilizing their own strength, and inside the individual parts of a car there are also a great many bearings in use.

Transmissions can be classified into two broad categories: manual and automatic. In cars with manual transmissions, a gear stick used to operate it is installed next to the driver's seat.

Fig. 2: The gear stick used to operate a manual transmission

Fig. 2: The gear stick used to operate a manual transmission

The driver operates the gear stick manually, in order to convert the power from the engine into a force appropriate for the situation in which the driver is driving.

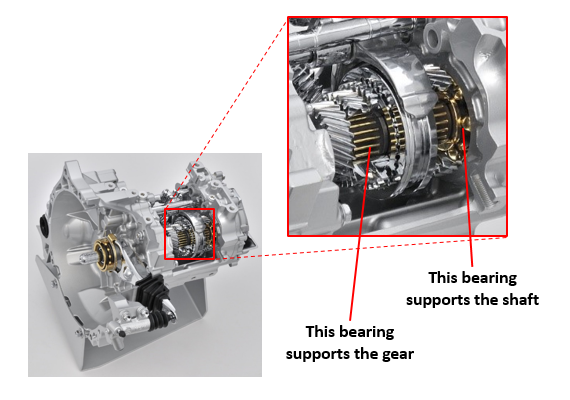

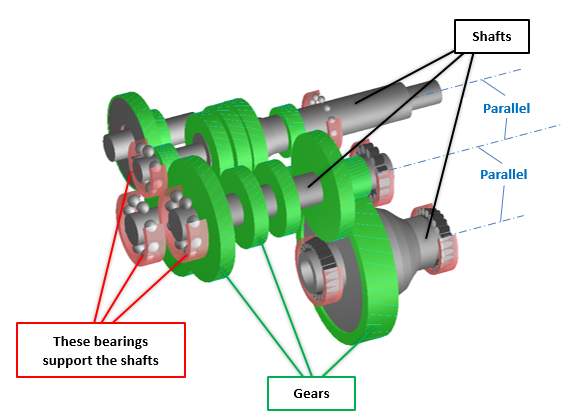

The manual transmission consists of shafts and gears. These parts are supported by bearings, and we would now like to introduce those bearings.

Fig. 3: The structure of a manual transmission

Fig. 3: The structure of a manual transmission

Fig. 4: How a manual transmission works

Fig. 4: How a manual transmission works

Bearings that support shafts

A bearing, of a type to match the magnitude of the power from the engine, is used, and it supports both the rotation of the shafts and the force being applied by the gears.

Table 1: Bearings that support shafts

| Radial load | Axial load | Type of bearing |

|---|---|---|

| Small | Small | Deep groove ball bearing |

| Big | Small | Cylindrical roller bearing |

| Big | Big | Tapered roller bearing |

We explained about radial and axial loads in Part 4, so please check there as well if you haven't already.

Fig. 5: Deep groove ball bearings for supporting shafts

Fig. 5: Deep groove ball bearings for supporting shafts

Bearings that support gears

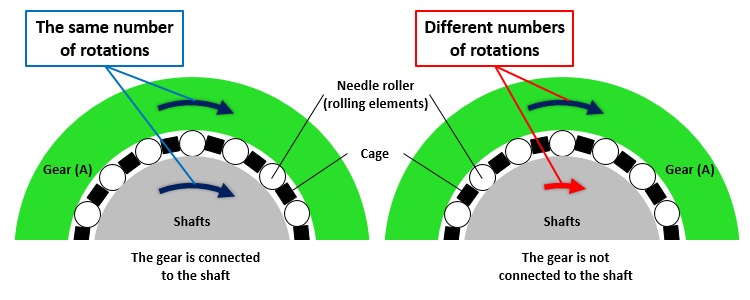

In a manual transmission, gears remain in rotation and interlocking with each other at all times.

In order to convey the appropriate driving force to the wheels for the speed we want to travel, we use the gear stick to select the gear (A) that best fits that driving force. The selected gear (A) is connected to the shaft, and rotates the shaft the same number of times.

In order to transmit a different driving force to the wheels for the changed situation, we use the gear stick to disconnect the connected gear (A) from the shaft and select the gear (B) that best fits that driving force. The selected gear (B) is connected to the shaft, and rotates the shaft with the same number of rotations.

In this case, the gear that is disconnected from the shaft (A) rotates independently of the shaft.

Just as the gear and the shaft have a different number of rotations, the needle roller bearing (a combination of needle rollers and cages) is mounted between the gear and the shaft, and rotates between the inside surface of the gear and the outside surface of the shaft.

Fig. 6: The numbers of rotations of gears and shafts used to increase or decrease speed

Fig. 6: The numbers of rotations of gears and shafts used to increase or decrease speed

Fig. 7: A bearing (combination of needle rollers and cages) for supporting a gear

Fig. 7: A bearing (combination of needle rollers and cages) for supporting a gear

3. Bearings used in differential gears

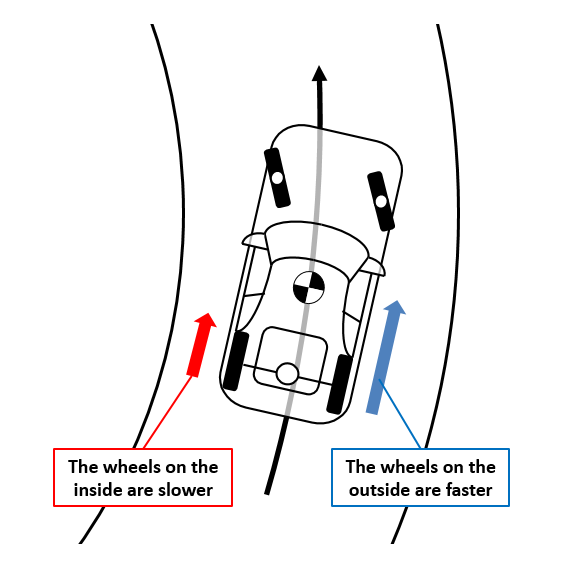

When a car turns left or right, the wheels on the inside rotate slower than the wheels on the outside.

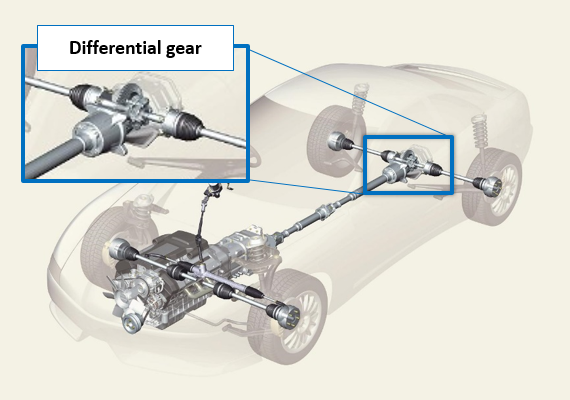

The differential gear is a device that converts the driving power from the transmission into even greater driving power and allows for different numbers of rotations for the left and right wheels.

Fig. 8: Wheel rotation when a car turns

Fig. 8: Wheel rotation when a car turns

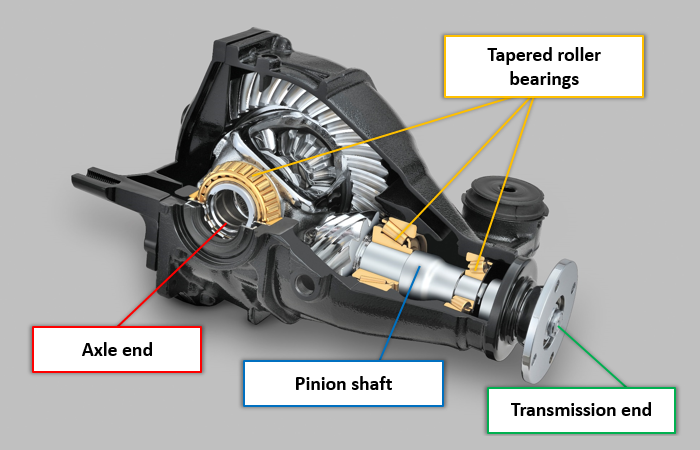

At the differential gear, gears attached to the pinion shaft (the shaft connected to the transmission) and the shaft on the wheel end interlock at a right angle. Bearings support both the rotation of the shafts and the force being applied by the gears.

Fig. 9: The layout of a differential gear

Fig. 9: The layout of a differential gear

Fig. 10: The structure of a differential gear

Fig. 10: The structure of a differential gear

Tapered roller bearings that support shafts

The combined tapered roller bearings simultaneously support both the radial and the axial load (in both directions), and by maintaining the correct interlocking of gears transmit a large amount of driving force to the wheels on both sides.

JTEKT provides the best low-friction torque tapered roller bearings in the world, which allow for an extremely small loss of driving force during rotation. On top of this, we are also making compact bearings a reality, greatly contributing to a decrease in CO2 emissions from cars.

Fig. 11: Low-friction torque tapered roller bearings

Fig. 11: Low-friction torque tapered roller bearings

Click here for more information on the JTEKT "LFT-Series of low-friction torque tapered roller bearings

* "LFT" is an abbreviation for "Low-Friction Torque," and is a registered trademark of JTEKT.

Conclusion

In this part we explained about the bearings that are used in devices that transmit power from the engine to the wheels, but there are a great many bearings used in the other parts of cars. By utilizing the strengths of each of the bearings, we increase the driving performance and safety of automobiles.

In order to achieve safer and more comfortable driving, there is a greater and greater demand for bearings with both high functionality and high reliability.

If you would like to know more about those bearings used in cars that we did not introduce on this column, please click the link below.