Bearing Trivia

Bearing Trivia for Beginners 3: "Bearing Materials (Part 2: Bearings for Extreme Special Environments)"

- Bearing Trivia for Beginner

To the readers of Bearing Trivia,

Your Bearing Trivia reporter, Mr. X here!

This entry continues on from "Bearing Materials (Part 1)" to introduce the materials used in bearings for extreme special environments.

1. Materials used in bearings for extreme special environments

A bearing is a component used in a great many machines that rotates smoothly while supporting a load (force).

In particular, bearings used for medical devices and devices for manufacturing microelectronic components such as semiconductors, flat-screen displays, storage media, need to be used in special environments (clean, vacuum, corrosive, high-temperature, etc.). Bearing need to have special properties (such as insulation or being non-magnetic) for certain applications (see Table 1).

Table 1: Applications of bearings for extreme special environments

|

Bearing environment |

Applications of bearings for extreme special environments |

|||

|---|---|---|---|---|

|

Semiconductor manufacturing equipment |

Equipment for manufacturing flat-screen (LCD or plasma) displays |

Equipment for manufacturing storage media (hard disk drives) |

Medical devices (MRI, etc.) |

|

|

Clean |

✔ | ✔ | ✔ | ✔ |

|

Vacuum |

✔ | ✔ | ✔ | ✔ |

|

Corrosive |

✔ | ✔ | ||

|

High-temperature |

✔ | ✔ | ✔ | |

|

Non-magnetic |

✔ | ✔ | ✔ | |

|

Insulated |

✔ | |||

Fig. 1: MRI (magnetic resonance imaging) that uses bearings for extreme special environments

This entry will introduce the materials and lubricants used in bearings for extreme special environments.

JTEKT has given its line of bearings for extreme special environments the name "EXSEV® Series".

2. Bearing ring and rolling element materials

For the material used in bearing rings and rolling elements, high carbon chromium bearing steel, which is generally resistant to rolling fatigue, is used. However, because environments such as clean and vacuum environments prevent the application of anti-corrosion oil to the bearings, high carbon chromium bearing steel cannot be used due its lack of corrosion resistance. For this reason, it is necessary to select either special steel or a ceramic material that is appropriate for the usage environment and properties.

1) Special steel

Table 2 shows the properties and appropriate usage environments of the major special steel materials.

Table 2: The properties and appropriate usage environments of major special steel materials

|

Special steel (major steel: standard number) |

Property |

Suitable environment |

Remarks |

||

|---|---|---|---|---|---|

|

Rolling fatigue strength |

Low gas emission |

Corrosion resistance |

|||

|

Martensitic stainless steel |

+++ | +++ | + |

Clean Vacuum |

|

|

Precipitation hardening stainless steel (JIS SUS630) |

++ | +++ | ++ |

Corrosive |

Limited usage load |

|

High speed tool steel |

+++ | +++ | - |

High-temperature (300°C or higher) |

|

|

Non-magnetic stainless steel |

++ | +++ | + |

Non-magnetic |

|

|

<For comparison> |

+++ | +++ | - | ||

* JIS (Japanese Industrial Standards) or ANSI (American National Standards Institute)

+++ Excellent、++ Good、+ Fair、- Unacceptable

- a) In clean and vacuum environments, anti-corrosion oil will contaminate the environment (and therefore cannot be used), so martensitic stainless steel (JIS SUS440C) is used, as it has excellent corrosion resistance.

- b) In corrosive environments, martensitic stainless steel is used. In harsher corrosive environments, precipitation hardening stainless steel (JIS SUS630) is used, but because precipitation hardening stainless steel has insufficient rotation fatigue resistance, there is a limit on the usage load.

- c) In high-temperature environments, martensitic stainless steel is used at temperatures up to 300°C. For temperatures higher than 300°C, high-speed tool steel (JIS SKH4 or ANSI M50) is used.

Ceramic material

Table 3 shows the properties and appropriate usage environments of the major ceramic materials.

Table 3: The properties and appropriate usage environments of major special ceramic materials

|

Ceramic material |

Property |

Suitable environment |

Remarks |

|||

|---|---|---|---|---|---|---|

|

Density g/cm3 |

Rolling fatigue strength |

Impact strength |

Heat resistance |

|||

|

Silicon nitride(Si3N4) |

3.2 | +++ | +++ | 800 | Vacuum Corrosive High temperature |

|

|

Zirconia |

6 | ++ | + | 200 | Corrosive |

Limited usage load |

|

Silicon carbide(Si3C) |

3.1 | + | + | 1,000 or higher | Corrosive Ultra-high temperature |

Limited usage load |

|

<For comparison> |

7.8 | +++ | +++ | 180 | ||

Ceramic materials are excellent in vacuum, corrosive, and high-temperature environments, and also have the benefits of being both highly non-magnetic and highly insulative.

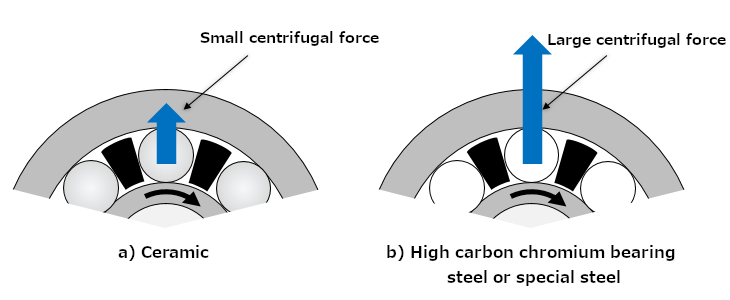

Since ceramic materials have a lower density than special steel, there is a lower centrifugal force of the rolling elements (see Figure 2). This makes ceramic materials suitable for high-speed rotation.

Fig. 2: Centrifugal force of the rolling elements

3. Ceramic bearings

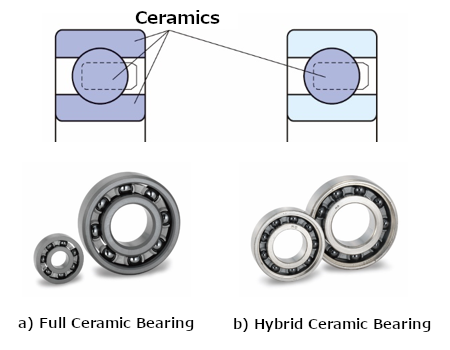

Ceramic bearings come in two basic types: full ceramic bearings and hybrid ceramic bearings. In the former, both the bearing rings and rolling elements are made of ceramic materials, whereas in the latter only the rolling elements are ceramic (see Figure 3).

Fig. 3: Ceramic bearings

In combination ceramic bearings, the inner and outer rings are made of a material that is appropriate for the application.

Note that metal, resin, or other materials are used for cages depending on the usage environment and conditions.

4. Lubricant

Lubricant plays a major role in facilitating the stable and smooth rotation of the bearing.

For more details, see:

What's the Structure of the Bearing? The role of the structure and parts in reducing friction

There are two types of lubricant used in bearings for extreme special environments: solid lubricants and grease.

1) Grease

Grease lubrication is superior to solid lubrication and is used in cases where only a very small amount of oil evaporation is acceptable. Fluorinated grease is chemically stable at low vapor pressure, and is used mainly at atmospheric temperatures or 200°C or lower.

2) Solid lubricants

Solid lubricants are used in clean, ultrahigh vacuum, and high-temperature environments (where grease cannot be used), or where oil evaporation from the grease cannot be allowed.

Table 4 shows the properties and appropriate usage environments of the major solid lubricants.

Table 4: The properties and appropriate usage environments of major solid lubricants

|

Type |

Solid lubricant |

Property |

Suitable environment |

|||

|---|---|---|---|---|---|---|

|

Thermal stability, °C |

Low particle emission |

Low gas emission |

||||

|

Atmosphere |

Vacuum |

|||||

|

Soft metals |

Silver |

― | 600 or higher | + | +++ |

Ultrahigh vacuum environments |

|

Layer lattice materials |

Molybdenum disulfide |

350 | 1,350 | + | ++ |

Vacuum or high-temperature environments |

|

Tungsten disulfide(WS2) |

425 | 1,350 | + | ++ | ||

|

Polymeric materials |

Polytetrafluoroethylene(PTFE) |

260 | 260 | +++ | + |

Clean, vacuum, or corrosive environments |

+++ Excellent、++ Good、+ Fair

a) Soft metal-based solid lubricants

Soft metal-based lubricants are suitable for ultrahigh vacuum environments because of their low gas emission from the bearing. These lubricants are used by coating the rolling elements (see Figure 4).

Fig. 4: Silver-coated rolling elements (balls)

b) Layer lattice-based solid lubricants

Thermally stable, layer lattice materials are well-suited to high-temperature environments. They are used by coating the bearing rings and cage, or by including them in the cage material. However, layer lattice materials emit a large amount of particles, making them unsuitable for clean environments.

c) Polymeric solid lubricants

Polymeric materials, which have low particle emission, are suitable for clean and corrosive environments, as well as for use in atmospheric and vacuum environments and with repeated usage conditions. Polymeric solid lubricants are used by coating the bearing rings and cage, or as the cage material.

5. How to select the right materials used in bearings for extreme special environments

The optimal combination of materials in used in bearings for extreme special environments is selected (from a variety of combinations meeting the conditions for the operating environment and properties) by examining the detailed operating conditions (such as temperature, load, and rotation speed).

Table 5 shows several examples of materials for bearings used in clean environments.

Table 5: Examples of materials for bearings used in clean environments

|

Cleanness (class) |

Atmospheric temperature |

Material |

Lubricant |

Photo |

|||

|---|---|---|---|---|---|---|---|

|

Bearing ring |

Rolling element |

Cage |

Shield |

||||

| High (10~100) |

200 or less |

Martensitic stainless steel |

Austenitic stainless steel |

Fluoropolymer coating (bearing rings and rolling elements) |

Fig. 5 |

||

| Mid (100~1,000) |

200 or less |

Martensitic stainless steel |

Austenitic stainless steel |

Fluorine-based grease-filled |

Fig. 6 |

||

Fig. 5: Bearings for clean environments (fluorine polymer coating)

Fig. 5: Bearings for clean environments (fluorine polymer coating)

Fig. 6: Bearings for clean environments (fluorinated grease-filled)

Fig. 6: Bearings for clean environments (fluorinated grease-filled)

6. Conclusion

- For the material used in bearing rings and rolling elements of bearings for extreme special environments, it is necessary to select either high carbon chromium bearing steel, special steel, or a ceramic material that is appropriate for the usage environment and properties. Ceramic materials are excellent in vacuum, corrosive, and high-temperature environments, and also have the benefits of being both non-magnetic and highly insulative.

- For the lubricant used in bearings for extreme special environments, there are solid lubricants and grease.をThere are two types of lubricant used in bearings for extreme special environments: solid lubricants and grease.

- The optimal combination of materials used in bearings for extreme special environments is selected (from a variety of combinations meeting the conditions for the operating environment and properties) by examining the detailed operating conditions (such as temperature, load, and rotation speed).

For more details, see:

Special Environment Ball Bearings

Look forward to the next "Bearing Trivia for Beginners"!