Bearing Trivia

Bearing Trivia for Beginners 4: "Bearing Cages"

- Bearing Trivia for Beginner

To the readers of Bearing Trivia,

Your Bearing Trivia reporter, Mr. X here!

A bearing is a component used in a great many machines that rotates smoothly while supporting a load (force).

In this column, we will be looking at the roles and types of bearing cages as well as their effects on bearing performance.

1. The structure of bearings

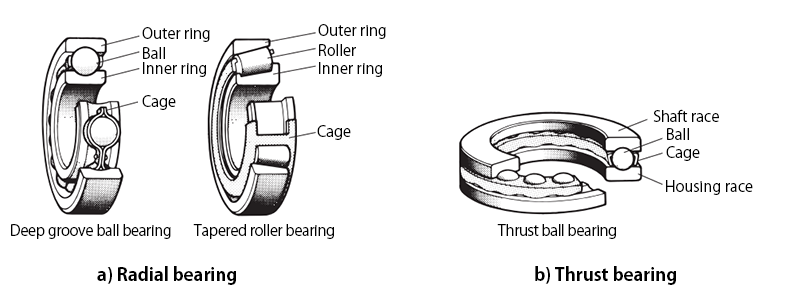

As shown in Figure 1, the components that make up the bearing are as follows:

● Bearing rings (races) ... The ring-shaped components

Radial bearings have inner and outer rings, while thrust ball bearings have shaft and housing races.

● Rolling elements ... The components that roll between the bearing rings (races); Rolling elements can be either "balls" or "rollers".

● Cage ... The component that maintains a fixed gap so the rolling elements don't contact with each other.

Figure 1: Bearing structure example

2. Role of cages

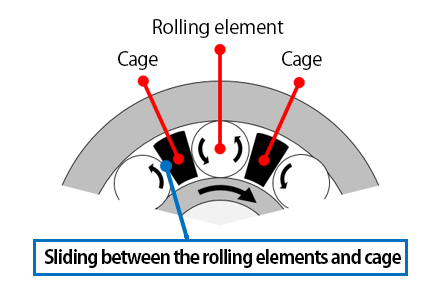

Cages are used to keep the rolling elements separated from each other, which allows them to roll smoothly.

The cage comes in contact with the rolling elements or bearing rings by sliding, and, when a force is applied to the bearing or the rotation is accelerated or decelerated, the rolling elements exert a force by pushing or pulling on the cage (see Figure 2).

The rolling element slides along the cage pocket, which can prevent the cage from rotating smoothly.

This is why selecting a cage type and material that is suitable for the bearing application is important.

Figure 2: Role of cages

For more information on the role of cages, see the following:

Cages -- What's the Structure of the Bearing? The role of the structure and parts in reducing friction

Cage Materials -- Bearing Trivia for Beginners 2: "Bearing Materials (Part 1: General Information)"

3. Cage types

Table 1 shows the different cage types and materials.

Cage types include the conventional (1) pressed cage, (2) machined cage, and (3) pinbtype cage.

In recent years, (4) molded cages have also become popular for reduced bearing weight and improved performance.

Table 1: Major cage types and materials

| Cage type | Features | Suitable material | ||||

| Metal | Synthetic resin | |||||

| Steel sheet | Carbon steel | Brass | ||||

| ① | pressed cage | Pressed with a die | ✔ | |||

| ② | Machined cage | Machined metal or resin lumps | ✔ | ✔ | ||

| ③ | Pin type cage | Includes pins passed through the center of hollow rollers and secured by a ring-shaped plate | ✔ | |||

| ④ | Molded cage | Molded by adding resin into a mold | ✔ | |||

There are many types of cage for each bearing type, with some adopting names that describe the characteristics of the cage shape.

In this section, we'll go over some of the typical cage types and shapes for each type of bearing with a focus on radial bearings.

1) Deep groove ball bearings

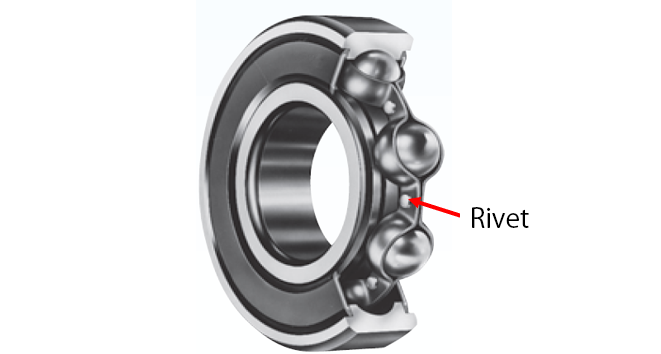

Pressed cages, like the one shown in Figure 3, are often used for small deep groove ball bearings.

The two ribbon type cages are riveted together.

Figure 3: Pressed cage (ribbon type cage) for deep groove ball bearing

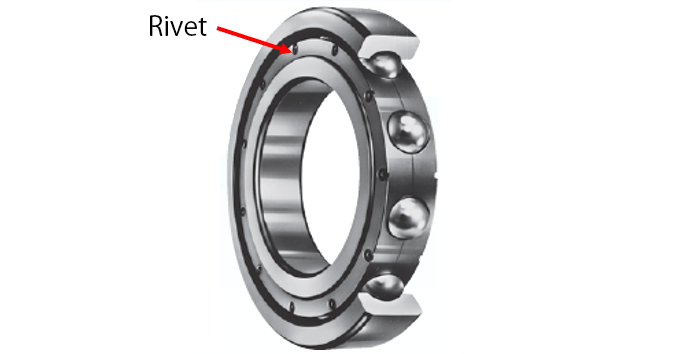

For medium-sized deep groove ball bearings, machined cages as shown in Figure 4 are used.

The two machined cages are riveted together.

Figure 4: Machined cage for deep groove ball bearing

Use of synthetic resin molded cages like the one shown in Figure 5 has increased in recent years for a variety of bearings, including small deep groove ball bearings, for reduced weight and improved performance.

Figure 5: Molded cage for deep groove ball bearing

2) Angular contact ball bearings

Machined cages like the one shown in Figure 6 are often used for angular contact ball bearings.

Figure 6: Machined cage for angular contact ball bearing

S type cages (Figure 7) are used for double-row angular contact ball bearings.

The S type cages are also used for double-row deep groove ball bearings.

Figure 7: Pressed cage (S type cage) for double-row angular contact ball bearing

3) Self-aligning ball bearings

For self-aligning ball bearings, staggered type (Figure 8) or snap type (Figure 9) are used.

Figure 8: Pressed cage (staggered type) for self-aligning ball bearing

Figure 9: Pressed cage (snap type) for self-aligning ball bearing

Molded cages like the one shown in Figure 10 have also been used for self-aligning ball bearings in recent years.

Figure 10: Molded cage for self-aligning ball bearing

4) Cylindrical roller bearings

Figure 11 shows a pressed cage commonly used for small cylindrical roller bearings.

Figure 11: Pressed cage for cylindrical roller bearing

For medium-sized double-row cylindrical roller bearings, machined cages like the one in Figure 12 are used.

Figure 12: One-piece type machined cage for double-row cylindrical roller bearing

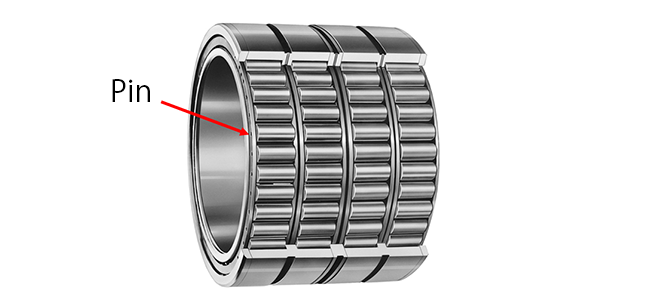

For large cylindrical roller bearings, pin type cages like the one shown in Figure 13 are sometimes used.

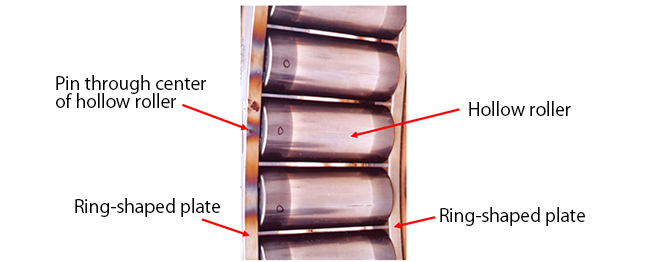

As shown in Figure 14, pin type cages use pins that are passed through the center of hollow rollers and secured by a ring-shaped plate, allowing for a large number of rollers to be used.

Figure 13: Pin type cage for four-row cylindrical roller bearing

Figure 14: Enlarged view of pin type cage

5) Tapered roller bearings

Tapered roller bearings like the one in Figure 15 often use pressed cages.

Because of this shape, these cages are also called window-type cages.

Figure 15: Window type pressed cage for tapered roller bearing

Pin type cages (Figure 13 and Figure 14) are sometimes used for large-sized tapered roller bearings.

6) Spherical roller bearings

Pressed cages like the one in Figure 16 are often used for pressed cages for spherical roller bearings.

Figure 16: Pressed cage for spherical roller bearing

For machined cages for spherical roller bearings, one-piece type machined cages (Figure 17) or prong type machined cages (Figure 18) are used.

Figure 17: One-piece type machined cage for spherical roller bearing

Figure 18: Prong type machined cage for spherical roller bearing

4. Effect of cage on bearing performance

When a force is applied to the bearing or the rotation is accelerated or decelerated, the rolling elements exert a force by pushing or pulling on the cage.

As such, machined metal cages with high strength are used to prevent cage damage when large force is applied or when rotation acceleration/deceleration is severe.

For high-speed rotating machine tool bearings, strong, lightweight, and low-friction molded synthetic resin cages (Figure 19 and Figure 20) are used.

Figure 19: Molded cage for machine tool angular contact ball bearing

Figure 20: Molded cage for cylindrical roller bearing for machine tool application

Click here for details on molded cages for machine tool bearings.

5. Conclusion

1) Cages are used to keep the rolling elements separated from each other, which allows them to roll smoothly.

2) When a force is applied to the bearing or the rotation is accelerated or decelerated, the rolling elements exert a force by pushing or pulling on the cage.

3) This is why selecting a cage type and material that is suitable for the specific bearing shape and application is important.

Look forward to the next "Bearing Trivia for Beginners"!