Bearing Trivia

Bearing Failure (Part 3): Causes and countermeasures for bearing failure (II)

- #3 Bearing Failure

In Part 2, from among the various types of bearing failure, we explained the characteristics and the typical causes and countermeasures that can be taken for the following types:

- Flaking

- Wear and fretting

- Cracking and chipping

- Brinelling and nicks

- Scratching and scuffing

Bearing Failure (Part 2)

In this part, we will explain the characteristics of the other types of bearing failure, their typical causes, and countermeasures that can be taken. Table and image (figure) numbers are the same as in Part 2 for those that are common to both entries, and will continue counting up for items that are new to Part 3.

Please note that while the JTEKT rolling bearing catalog uses the terms "bearing" and "rolling bearing" interchangeably, this column does not use the term "rolling bearing" as a general rule.

1. Types of bearing failure and where they occur

Table 1 shows the types of bearing failure and where they occur. Please refer back to Part 1 for the names of the various components of the bearing.

Table 1: Types of bearing failure and where they occur

| No. |

Failure type |

Rings and rolling elements |

Rings |

Cage |

|||

|

Raceway surface and rolling surface |

Roller guide surface, cage guide surface, roller end face |

Other |

Fitting surface |

Pocket, guide surface |

Rivet |

||

| 1 |

Flaking (spalling) |

✔ | |||||

| 2 |

Wear |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

Fretting |

✔ | ✔ | |||||

| 3 |

Cracking |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

Chipping |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 4 |

Brinelling |

✔ | ✔ | ✔ | ✔ | ||

|

Nicks |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 5 |

Scratching |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

Scuffing |

✔ | ✔ | ✔ | ✔ | |||

| 6 |

Rust |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

|

Corrosion |

✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 7 |

Pear skin (speckles) |

✔ | |||||

|

Discoloration |

✔ | ✔ | ✔ | ✔ | |||

| 8 |

Smearing |

✔ | ✔ | ||||

| 9 |

Creep |

✔ | |||||

| 10 |

Electric pitting |

✔ | ✔ | ||||

| 11 |

Seizure |

✔ | ✔ | ✔ | ✔ | ✔ | |

| 12 |

Cage damage |

✔ | ✔ | ||||

To see the names of all the various bearing components, please see the following:

2. Causes and countermeasures for bearing failure

In this part, from among the types of bearing failure listed in Table 1, we will explain the characteristics and the typical causes and countermeasures that can be taken for the following types:

- Rust and corrosion

- Pear skin and discoloration

- Smearing

- Creep

- Electric pitting

- Seizure

- Cage damage

For a more detailed discussion of the causes and countermeasures, please see the following:

Causes and countermeasures: Ball & Roller Bearings Catalog

Failure examples: Ball & Roller Bearings: Failures, Causes and Countermeasures

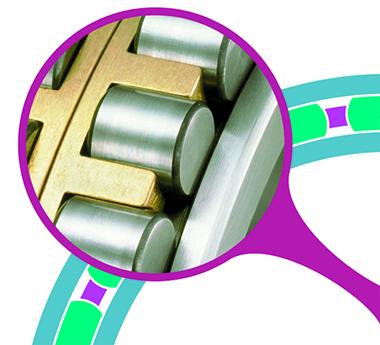

1) Rust and corrosion

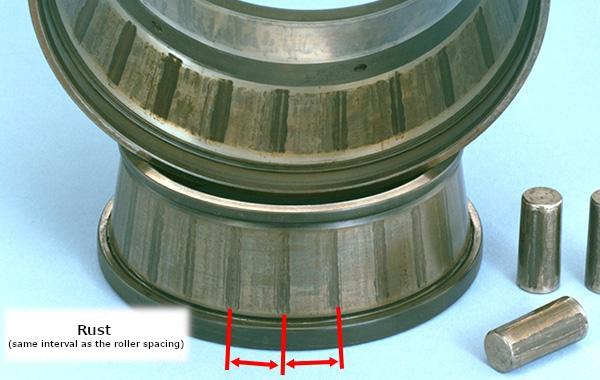

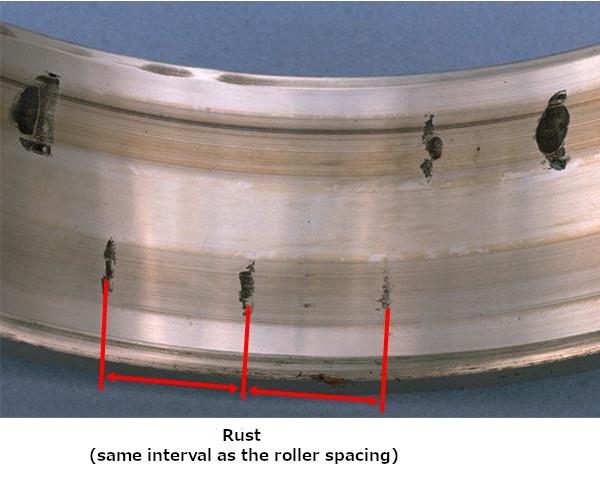

"Rust" is a film of oxides, or hydroxides, or carbonates formed on a metal surface due to a chemical reaction (see Figures 8 a) and 8 b)). Corrosion is a phenomenon in which a metal surface is eroded by a chemical reaction with an acid or alkaline solution, resulting in oxidation or dissolution.

Fig. 8 a): Rust [inner and outer ring raceway surfaces and roller rolling surface of a tapered roller bearing]

Fig. 8 b): Rust [outer ring raceway surface of a double-row cylindrical roller bearing]

Table 9 shows the typical causes of, and countermeasures against, rust and corrosion.

Table 9: Typical rust and corrosion causes and countermeasures

|

Rust/Corrosion condition |

Cause(s) |

Countermeasure(s) |

|

Partially or completely covering the bearing surface |

・ Improper storage condition |

・Improve the bearing storage condition |

|

Rust and corrosion at the same interval as the rolling element spacing |

・Contamination by water or corrosive matter |

・Improve the sealing device |

2) Pear skin (speckle) and discoloration

"Pear skin" is a phenomenon in which minute brinell marks cover the entire rolling surface, caused by the entry of foreign matter. Pear skin is characterized by a loss of luster and a rolling surface that is rough in appearance, and in extreme cases this is accompanied by discoloration due to heat generation. (See Figure 9 a).)

"Discoloration," meanwhile, is a phenomenon in which the surface color changes because of staining or heat generation during rotation (see Figure 9 b)).

Fig. 9 a): Pear skin [inner ring raceway surface of a deep groove ball bearing]

Fig. 9 b): Discoloration [inner and outer ring raceway surfaces and roller rolling surface of a cylindrical roller bearing]

Table 10 shows the typical causes of, and countermeasures against, pear skin and discoloration.

Table 10: Typical pear skin and discoloration causes and countermeasures

|

Discoloration/Pear skin condition |

Cause(s) |

Countermeasure(s) |

|

Pear skin-like indentation marks on a raceway surface or rolling surface |

・Entry of a large amount of tiny particles of foreign matter |

・Clean the bearing and the area around it |

|

Discoloration of the raceway surface, rolling surface, rib surface, or cage guide surface |

・The internal clearance is too small |

・Provide a proper internal clearance |

3) Smearing

"Smearing" is a phenomenon in which a cluster of tiny seizures cover the rolling contact surface (see Figures 10 a) and 10 b)). Since smearing is caused by high temperature due to friction, the surface of the material usually experiences partial melting, and smeared surfaces usually appear very rough.

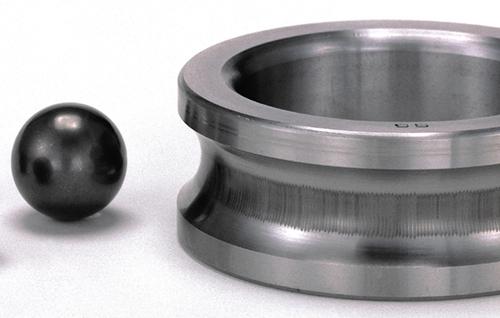

Fig. 10 a): Smearing [inner ring raceway surface of a deep groove ball bearing]

Fig. 10 b): Smearing [ball surface]

Table 11 shows the typical causes of, and countermeasures against, smearing.

Table 11: Typical smearing causes and countermeasures

|

Smearing condition |

Cause(s) |

Countermeasure(s) |

|

Occurring on a raceway surface or rolling surface |

・Improper or insufficient lubricant |

・Reexamine the selection of lubricant or lubrication method |

4) Creep

"Creep" is a phenomenon in which bearing rings move relative to the shaft or housing (see Figures 11 a) and 11 b)).

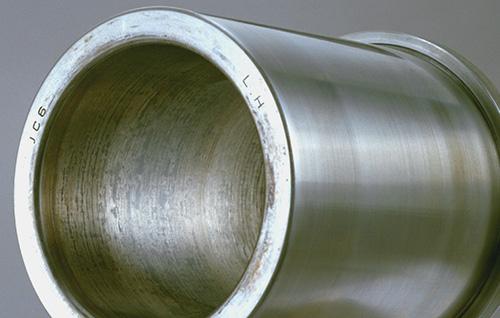

Fig. 11 a): Creep [inner ring bore surface of a double-row cylindrical roller bearing]

Fig. 11 b): Creep [outer ring outside surface of a deep groove ball bearing]

Table 12 shows the typical causes of, and countermeasures against, creep.

Table 12: Typical creep causes and countermeasures

|

Creep condition |

Cause(s) |

Countermeasure(s) |

|

Wear, discoloration, and scuffing caused by slipping on the fitting surfaces |

・Insufficient interference |

・Provide greater interference |

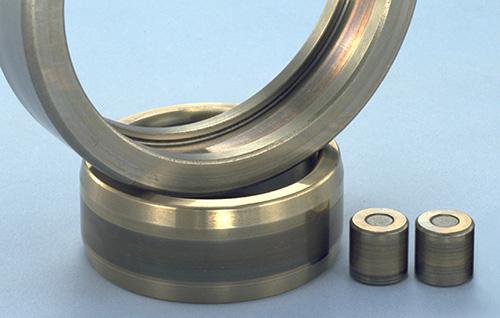

5) Electric pitting

"Electric pitting" refers to when an electric current passes through a bearing while in operation, generating sparks between the raceway and rolling elements through a very thin oil film, resulting in melting of the surface metal in this area.

It can result in what is called "pitting" (the emergence of tiny "cavities"; see Figure 12 a)) or in some cases the rolling surface can become corrugated (see Figure 12 b)).

Fig. 12 a): Electric pitting (pits) [inner ring raceway surface of a cylindrical roller bearing]

Fig. 12 b): Electric pitting (corrugation) [ball surface and inner ring raceway surface of a deep groove ball bearing]

Table 13 shows the typical causes of, and countermeasures against, electric pitting.

Table 13: Typical electric pitting causes and countermeasures

|

Electric pitting condition |

Cause(s) |

対策 Countermeasure(s) |

|

Occurring on a raceway surface or rolling surface |

・Sparks generated when electric current passes through a bearing |

・Prevent current from passing through the bearing |

6) Seizure

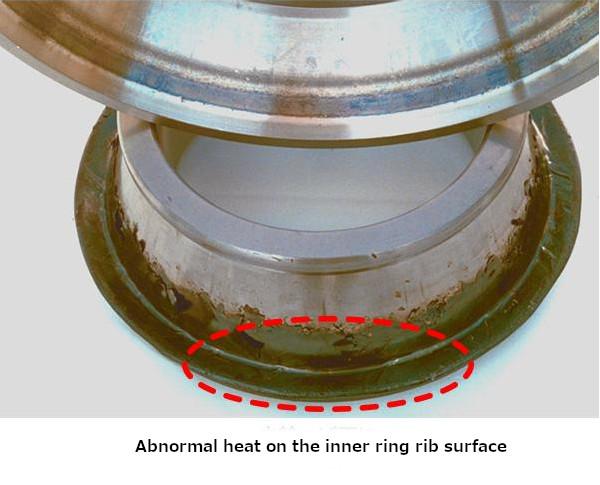

"Seizure" refers to when abnormal heat causes the bearing to partially melt, which leads to either the bearing losing the ability to rotate properly or the rolling or sliding surface becoming extremely rough (see Figures 13 a) and 13 b)).

Fig. 13 a): Seizure [tapered roller bearing]

Fig. 13 b): Seizure [cylindrical roller bearing with a rib]

Table 14 shows the typical causes of, and countermeasures against, seizure.

Table 14: Typical seizure causes and countermeasures

|

Seizure condition |

Cause(s) |

Countermeasure(s) |

|

Discoloration, distortion, and melting together due to heat |

・The internal clearance is too small |

・Provide a proper internal clearance |

7) Cage damage

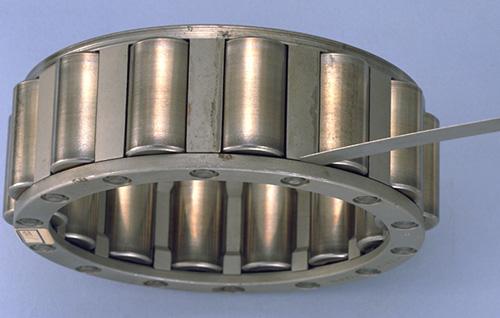

Since cages are made of materials that are relatively less hard, external pressure and contact with other components can easily produce flaws and distortion, and in severe cases chipping and cracking can occur (see Figures 14 a) through 14 e)).

Fig. 14 a): Cage distortion [cylindrical roller bearing]

Fig. 14 b): Cage cracking [deep groove ball bearing]

Fig. 14 c): Cage wear/cracking [tapered roller bearing]

Fig. 14 d): Cage rust [tapered roller bearing]

Fig. 14 e): Cage rivet looseness [cylindrical roller bearing]

Table 15 shows the typical causes of, and countermeasures against, cage damage.

Table 15: Typical cage damage causes and countermeasures

|

Cage damage condition |

Cause(s) |

Countermeasure(s) |

|

Flaws, distortion, chipping, cracking, and excessive wear in a cage |

・Extraordinary vibration, impact, or moment |

・Reexamine the load conditions ・Reexamine the selection of lubricant or lubrication method ・Improve mounting |

3. Conclusion

1) In "Bearing Failure (Part 3)," from among the various types of bearing failure, we explained the characteristics and the typical causes and countermeasures that can be taken for the following types:

- Rust and corrosion

- Pear skin and discoloration

- Smearing

- Creep

- Electric pitting

- Seizure

- Cage damage

2) When it comes to determining the cause of bearing failure, the following are all necessary:

- sufficient knowledge and experience regarding both bearings and lubrication;

- an awareness of the characteristics of the machine; and

- a familiarity with the bearing mounting conditions and operating history.

3) In recent years, with machines becoming smaller, lighter, and faster, the need has arisen for bearings to withstand more severer conditions than before. For this reason, you may encounter other types of bearing failure that we were unable to address in these past few entries.

4) If you have any technical questions regarding bearing failure, or opinions/thoughts on these "Bearing Trivia" pages, please feel free to contact us using the following form: