Bearing Trivia

Magnetic Bearings: Bearings that use magnetic force

- JTEKT Product Courses

In earlier "Bearing Trivia" columns, we showed you how to select the right bearings (rolling bearings) for machine design purposes in "How to Select the Right Bearing (Parts 1 to 8)."

This time, we'll talk about magnetic bearings, which can provide different features and performance than rolling bearings and plain bearings.

Structure of magnetic bearing

1. What are "magnetic bearings"?

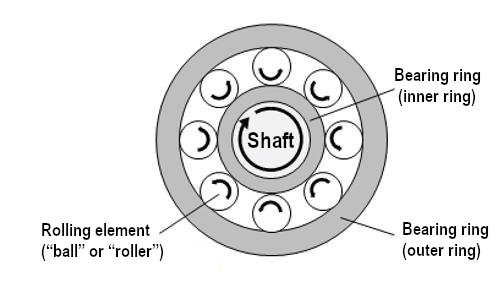

Let's first review the structure and mechanism of rolling bearings often used in general machinery.

Figure 1: Bearing structure

As you can see in Figure 1, bearings contain several rolling elements ("balls" or "rollers") arranged at regular intervals between bearing rings (inner and outer rings).

See the following for details on bearing structures and mechanisms.

Magnetic bearings are special because they do not have rolling elements. Instead, they use magnetic force to levitate and support the shaft without making contact. For this reason, they can be rotated very smoothly without any resistance from rolling friction.

Next, let's talk about the principles behind magnetic bearings.

2. Principles of magnetic bearings

Magnetic bearings use magnetic force (the attracting force of magnets) to support a rotating shaft.

As you can see in Figure 2, gravity is applied to the shaft in normal states without magnetic force. This prevents the shaft from maintaining its position, which causes it to drop.

Figure 2: When only gravity is applied with no magnetic force

However, the shaft can be supported without dropping by arranging magnets in a way that balances magnetic force (the force that attracts the shaft) with gravity (see Figure. 3).

Figure 3: Balancing magnetic force and gravity

With magnetic bearings, the electric current applied to the electromagnet can be adjusted to strengthen or weaken the magnetic force. This enables a balance with gravity to be achieved.

This mechanism is explained below and shown in Figure 4.

• First, a sensor observes the position of the shaft.

• Next, a controller adjusts the electric current applied to the electromagnet based on those observations.

• Finally, adjustments are made to balance the magnetic force of the electromagnet with gravity.

Figure 4: The principle behind magnetic force adjustments

3. The structure of magnetic bearings

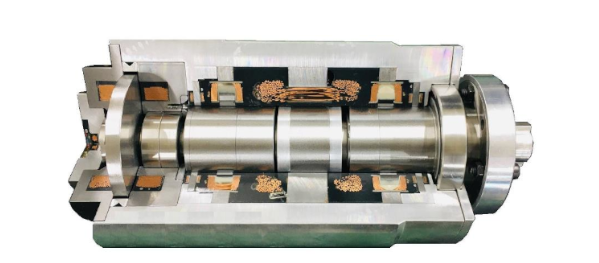

Figure 5 shows the structure of magnetic bearings.

Also, Table 1 shows the components of magnetic bearings and their roles.

Figure 5: Structure of magnetic bearing

Table 1: Components of magnetic bearings and their roles

| No. | Component | Role |

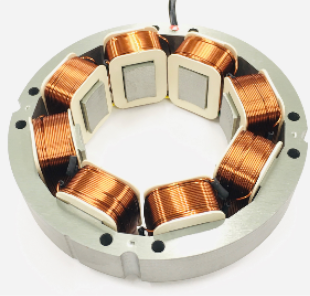

| ① | Radial magnetic bearing (See Figure 6) |

Supports force applied perpendicular to the shaft (radial direction) Includes multiple electromagnets to support force from any radial direction |

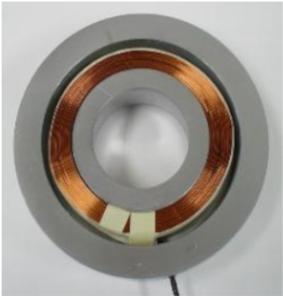

| ② | Axial magnetic bearing (See Figure 7) |

Includes electromagnets that generate magnetic force in the horizontal direction of the shaft, supporting force applied in the same direction as the shaft |

| ③ | Sensor | Observes the position of the shaft |

| ④ | Controller | Adjusts the electric current applied to the electromagnets of the magnetic bearing based on sensor observations of the shaft position |

|

|

|

Figure 6: Radial magnetic bearing |

Figure 7: Axial magnetic bearing |

4. Features of magnetic bearings

Magnetic bearings have the following structure:

• They support the shaft without making contact.

• A sensor is used to observe the shaft position, while a controller is used to adjust the magnetic force.

With this structure, they can provide different features and performance than other bearings.

Table 2 shows the features and effects of magnetic bearings.

Table 2: Features and effects of magnetic bearings

| No. | Structure | Feature | Effect |

| 1 | • Supports the shaft without making contact | Resistance (loss) is extremely low during rotation | • High-speed rotation is possible (See Figure 8) • Power loss at high speeds is low (See Figure 9) • Vibration and noise are low |

| Rotating parts do not suffer wear | • Rotating parts do not suffer wear and do not need to be replaced | ||

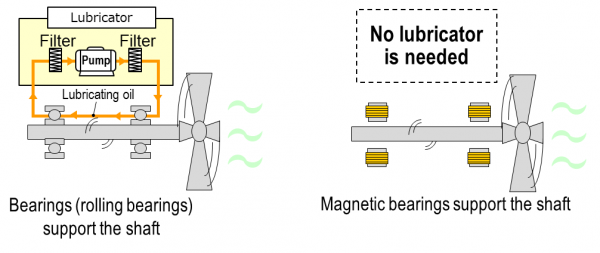

| No lubricants are needed | • They keep machines clean because there is no leaking or spattering of lubricants • They are environmentally friendly because they don't use lubricants • They enable equipment to be downsized because no space is needed for a lubricator (See Figure 12) |

||

| 2 | • A sensor observes the position of the shaft | Their status can be monitored by observing the shaft position | • Symptoms of malfunctions can be detected quickly because their status is monitored → This contributes to stable machine operation by preventing unexpected malfunctions and accidents |

Figure 8: Comparison of high-speed rotation performance

Figure 9: Comparison of power loss at high-speed rotation

As shown in Table 3, using magnetic bearings for machinery that operates for long periods of time means that periodic maintenance and inspections can be significantly reduced, which makes machine operation more stable.

Table 3: Reductions in periodic maintenance and stable operation in machines that use magnetic bearings

| No. | Feature of magnetic bearings | Effect |

| 1 | Rotating parts do not suffer wear | Rotating parts do not suffer wear and do not need to be replaced |

| 2 | No lubricants are needed | No replenishment or replacement of lubricants is needed |

| 3 | Sensors perform status monitoring so that symptoms of machine malfunctions can be detected quickly | They reduce unexpected machine stoppages and help machines operate stably for long periods of time |

5. Examples of magnetic bearing uses

Let's look at some typical uses of magnetic bearings.

1) High-speed rotating spindles

Figure 10 shows an example of magnetic bearings being used for a high-speed rotating spindle.

Both radial and axial magnetic bearings are used to support the spindle.

Ball bearings are also used for the touchdown bearings, which are used for protection in the event of an emergency stop.

Figure 10: High-speed rotating spindle

2) Facility machinery (downsizing and reduced periodic maintenance)

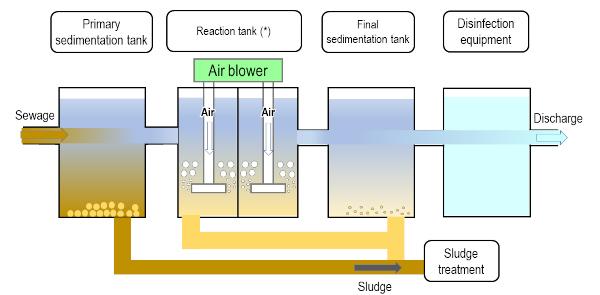

Let's look at magnetic bearings being used for the air circulator of a reaction tank for sludge treatment at a sewage treatment plant.

Note (*): The air blower sends air into the reaction tank to break down sludge using the power of microorganisms.

Figure 11: Location where the air circulator is used at the sewage treatment plant

Because magnetic bearings don't need lubricants (see Table 2), no space is needed for a lubricator. This enables machinery to be downsized (see Figure 12).

Figure 12: Machine (air blower) downsizing with magnetic bearings

Magnetic bearings can also greatly reduce periodic maintenance and help machines operate stably (see Table 3).

For more detailed information, please see the following:

Development of magnetic bearing products for air blowers used in sewage treatment plants

6. Conclusion

Magnetic bearings have the following structure:

(1) They support the shaft without making contact.

(2) A sensor is used to observe the shaft position, while a controller is used to adjust the magnetic force.

With this structure, they can provide different features and performance than other bearings (rolling bearings) such as:

• Resistance (loss) is extremely low during rotation

• Rotating parts do not suffer wear

• No lubricants are needed

• Their status can be monitored by observing the shaft position

For this reason, magnetic bearings are recommended for the following applications:

• High-speed rotating machines for which bearings cannot be used

• Machines in environments where lubricants cannot be used

• Machines that require stable operation over long periods

etc.

If you have any technical questions regarding magnetic bearings, or opinions/thoughts on these "Bearing Trivia" pages, please feel free to contact us using the following form.