Bearing Trivia

The Applications of Bearings II: This is how bearings are used for machines in industry

- #1 What Are Bearings?

Do you know what kinds of machines, apart from cars, use what kinds of bearings?

In Part 1 we explained how a bearing is a component that supports rotating shafts.

For this reason, it's safe to say with certainty that bearings are used in any machine that has a shaft.

In this part, we will continue on where the last part left off, and talk about the applications of bearings.

Specifically, we will now introduce the bearings used in machines in three fields: "generate energy", "creation of materials" and "machining."

1. Bearings that create energy: wind turbine generators

Electric power generators create the energy that we need in our day-to-day lives. In recent years there has been a greater interest in using to use green energy that does not emit CO2 (carbon dioxide), one of the gases that cause global warming. In particular, wind turbine generators have been popping up all over the world.

Maintenance inspections are difficult when such turbines are located in high located at a high altitude, and so there is increased demand for bearings that have a high degree of reliability (they hardly ever break) and a long lifespan.

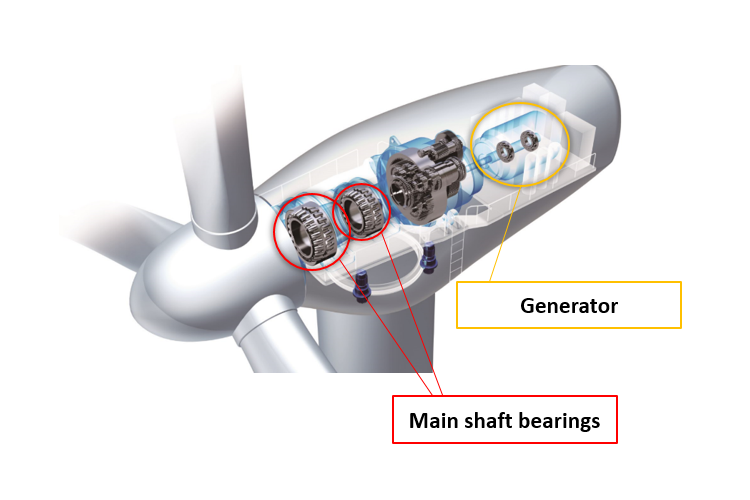

There are a lot of bearings that are used in wind turbine generators, but here we would like to introduce the "main shaft bearings" that receive force from the wind and convey rotation to the generator.

Fig. 1: High-altitude wind turbine generators

Fig. 1: High-altitude wind turbine generators

Fig. 2: The structure of a wind turbine generator

Fig. 2: The structure of a wind turbine generator

Main shaft bearings

In a wind turbine generator the force of the wind spins the main shaft, and that rotation is transmitted to the generator to generate electricity.

The main shaft bearings support not only the weight of the blades and the rotational part but also the force of the wind, whose force and direction change in an irregular manner.

For this reason, we mainly use spherical roller bearings, which are able to support a large amount of force and have an excellent aligning capability.

■ What is "aligning capability"?

This refers to the ability of the inner ring, rolling elements, and cage to continue to rotate, aligning themselves if they have become misaligned.

We also described the aligning capability of spherical roller bearings in Part 4: "What Are the Differences Between Bearings? The various types and special features of bearings," so please check that out if you haven't already (or if you need a refresher).

Furthermore, because they are able to support a large amount of force, we use large spherical roller bearings, with an outside diameter of 1 meter or more, for the main shaft.

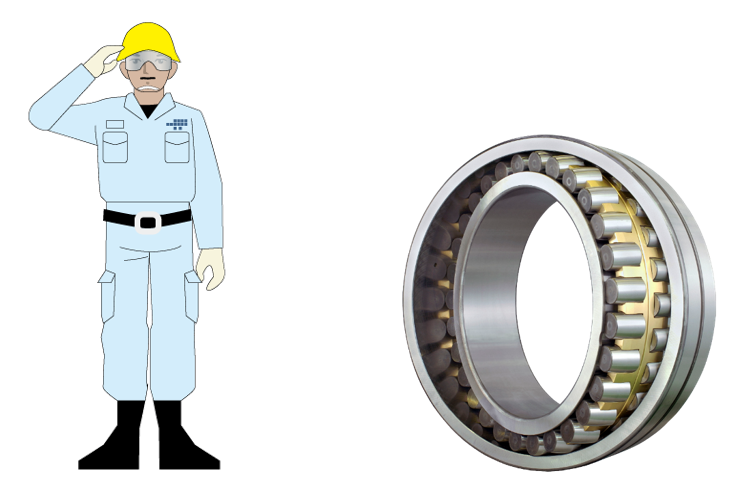

Fig. 3: A large-scale spherical roller bearing for the main shaft of a wind turbine generator

Fig. 3: A large-scale spherical roller bearing for the main shaft of a wind turbine generator

Click here for more information on our products for devices used in wind power generation

2. Bearings that create materials: steel rolling mills

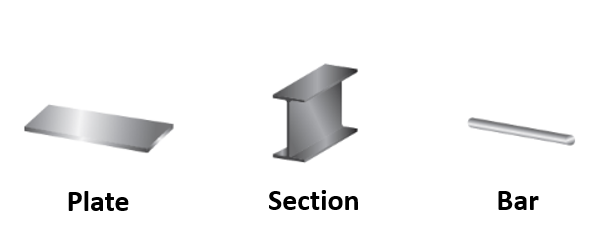

As a representative example of a machine that creates materials for things, we will now introduce the rolling mill, which turns steel materials into the shape needed to serve their purpose.

Fig. 4: Typical examples of steel shapes

Fig. 4: Typical examples of steel shapes

In a steel rolling mill, a steel sheet is passed through to rotating rolls, and force is applied to stretch it out. There is an old saying that goes "strike while the iron is hot." This saying is true: steel materials are usually rolled at a very high temperature. Here, bearings, under high-temperature conditions, support an exceedingly large amount of force to rotate the rolls.

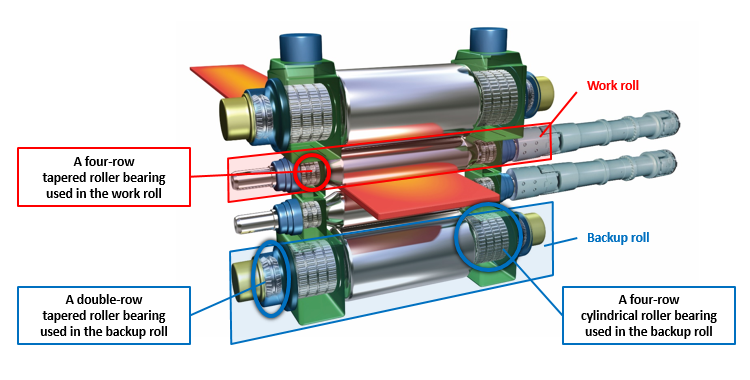

Fig. 5: The structure of a steel rolling mill

Fig. 5: The structure of a steel rolling mill

Bearings used in work rolls

In work rolls, we use four-row tapered roller bearings, in order to support the exceedingly large radial load and bi-directional axial load that are generated during rolling.

Fig. 6: A four-row tapered roller bearing for use in a work roll

Fig. 6: A four-row tapered roller bearing for use in a work roll

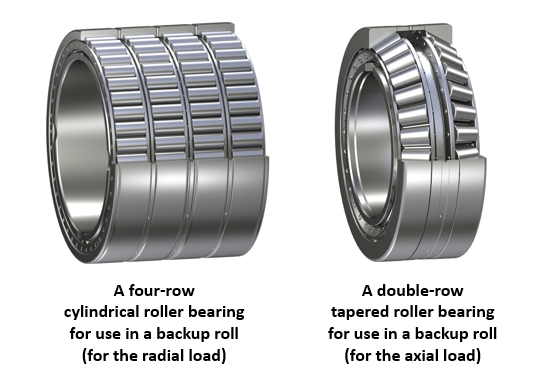

Bearings used in backup rolls

Work rolls, when rolling, can become warped easily due to the heavy load, but the backup roll protects against that warping. In backup rolls, we use four-row cylindrical roller bearings to support the exceedingly large radial load and double-row tapered roller bearings to support the axial load.

Fig. 7: Bearings for use in backup rolls

Fig. 7: Bearings for use in backup rolls

In 1943 JTEKT created the first steel rolling mill bearing in Japanese history, and ever since has been providing a large number of bearings for use not only in rolling mills but throughout the entire steel industry.

Click here for more information on bearings for use in steel rolling mills

Click here for more information on our products for use in steel production equipment

3. Bearings for machining: machining centers (machine tools)

Lastly, let's take a look at the mechanical devices used in machining.

Mechanical devices used in transforming ("machining") products and components into the optimal shape are called machine tools.

In particular, recent years have seen a rapid rise in the prevalence of machining centers that are used in machining and are controlled by computer.

Thanks to machining centers, minute and precise machining that cannot be performed by hand is made possible, and the time needed for machining is reduced dramatically.

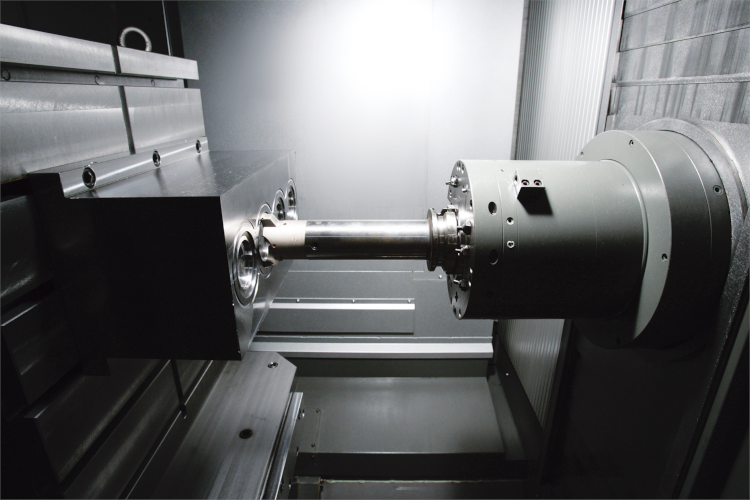

Fig. 8: A machine tool used in a machining center

Fig. 8: A machine tool used in a machining center

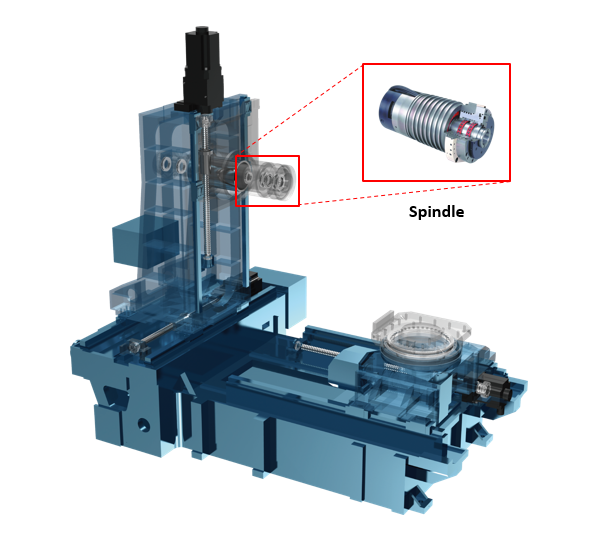

In the spindles attached to machining centers, we need to use bearings with a low temperature increase, so as not to cause warping of the product due to heat generation, or decreased precision of the machining.

Fig. 9: The structure of a machining center and its spindle

Fig. 9: The structure of a machining center and its spindle

Spindle bearings

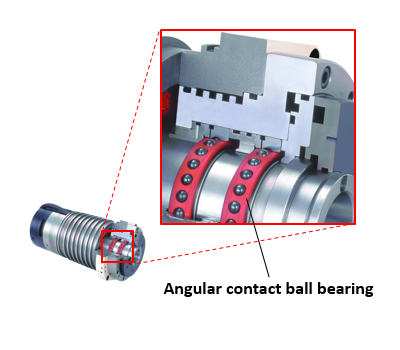

In spindles, we use angular contact ball bearings, which can simultaneously support a radial load and an axial load during machining.

Fig. 10: Angular contact ball bearings used in a spindle

Fig. 10: Angular contact ball bearings used in a spindle

JTEKT was the first in the world to produce ceramic bearings.

These ceramic bearings do not heat up much, even when rotating at high speed, and thus guard against the dimensional warping of the machined products.

In addition, they allow for the supply of only the necessary amount of lubricating oil, which is the cause of this heat generation, to the required areas, and to promptly discharge it.

Click here for more information on bearings for use in spindles

JTEKT is also manufacturing machine tools.

If you want to know more about JTEKT's machine tools, why not check out the following website?

Machine Tools & Mechatronics | JTEKT Corporation

Conclusion:Bearings support our daily lives

From machines that generate energy, to machines that create materials, to machining tools--we don't often witness these products directly in our day-to-day lives.

But, as we have introduced in this column, a great many bearings are used for machines in industry.

These bearings not only support the force and the rotation, but they support our daily lives.

Furthermore, the functionality that is demanded of bearings is increasing all the time, with bearings suited for different applications being highly sought after.