Bearing Trivia

How to Select the Right Bearing (Part 4): Bearing limiting speed, running accuracy, and fits

- #2 How to Select the Right Bearing

In Part 3, we explained about the dimensions and service life of a bearing.

How to Select the Right Bearing (Part 1): The order of priority for selecting bearings, and the types of bearings How to Select the Right Bearing (Part 2): How to decide the bearing arrangement How to Select the Right Bearing (Part 3): Bearing dimensions and service life

In Part 4, we will explain bearing limiting speed, running accuracy and fits, as measures for whether the bearing type you chose was appropriate.

When selecting a bearing, we need one that rotates stably and with the required accuracy, in a manner appropriate to the operating speed of the machine. What kind of things do we need to pay attention to when selecting bearings?

In Part 4, we will elaborate on the following two points you need to be aware of when selecting your bearing.

- The bearing should rotate stably and with the required accuracy at the operating speed of the machine.

- The bearing should have the fits and internal clearance necessary to satisfy its service life.

Table 1: Bearing selection checklist

| Order | Examination item | Major points to confirm |

|---|---|---|

| ① | Bearing type | What magnitude and direction of load do you need? Will it fit in the installation space? |

| ② | Bearing arrangement | Are you using two (or more) bearings on a single shaft? |

| ③ | Bearing dimensions and service life | Do the dimensions and service life satisfy your needs? |

| ④ | Bearing limiting speed, running accuracy, fits and internal clearance | Does it have the necessary running accuracy and rigidity for the machine? Does it have the fits and internal clearance to satisfy its service life? <This is the focus of Part 4> |

| ⑤ | Bearing preload and rigidity | Does it have the necessary rigidity for the machine? |

| ⑥ | Bearing lubrication | Can the bearing rotate stably over a long period of time? |

| ⑦ | Components around the bearing | What bearing surrounding structure/assembly are you looking for? |

| ⑧ | Bearing mounting and dismounting | Will it facilitate maintenance/inspection of the machine? |

1. Limiting speed and running accuracy

1) Limiting speed

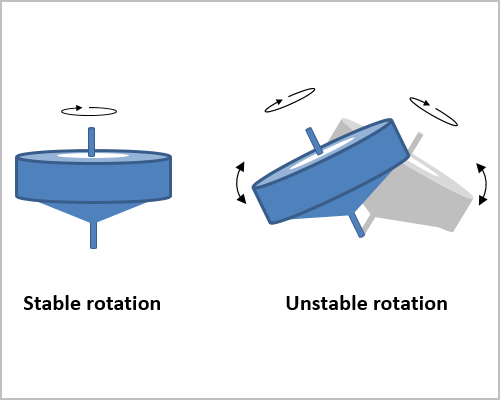

When a bearing rotates, its internal temperature rises due to friction resistance.

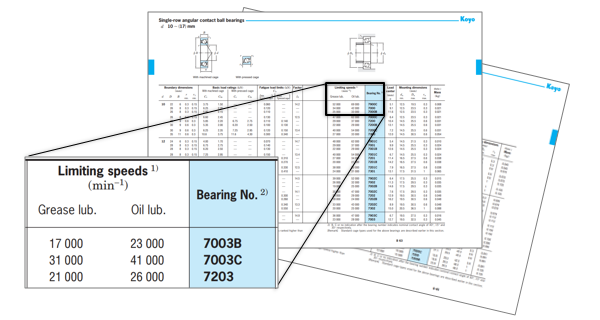

Once the bearing reaches a rotational speed equal to or greater than a certain amount, its temperature will increase tremendously, impairing the ability of the machine to run smoothly. This certain amount is called the "limiting speed." The specifications tables in our bearing catalog show the limiting speed for each bearing type and set of dimensions (see Table 2). You should select a bearing with a limiting speed that is higher than the rotational speed in accordance with the operating speed of the machine.

Table 2: Limiting speed

If a machine keeps running above the limiting speed of the bearing, the temperature of the bearing will increase dramatically, and potentially cause damage (seizure). (See Figure 1.)

Fig. 1: Bearing seizure

Fig. 1: Bearing seizure

Note that a limiting speed of the bearing is affected not only by the type and size of the bearing but is also greatly affected by such factors as its tolerance, cage type and material, type and amount of lubricant, lubrication method, and so on. For this reason, if you intend to use a bearing at a high rotational speed, please consult with JTEKT before making your decision.

2) Tolerance

Bearing tolerances for the boundary dimension accuracy and running accuracy of the bearings are specified (see Table 3), as well several types of tolerance classes for each individual bearing type (see Table 4).

Table 3: What makes up a bearing tolerances

| Bearing tolerance | |

|---|---|

| Boundary dimension accuracy | Running accuracy |

| Relates to the housing and shaft mounting | Relates to the runout of rotating elements |

Table 4: Bearing classes (JIS example)

| Tolerance | Standard |  |

Higher precision | ||

|---|---|---|---|---|---|

| Class | Class 0 | Class 6 | Class 5 | Class 4 | Class 2 |

Bearing type and tolerance class - Ball & Roller Bearings Catalog

Bearings of class 0 offer adequate performance for general applications.

Bearings of class 5 or higher are required for a precise running accuracy and a higher rotational speed, described in Table 5.

Table 5: High precision bearing applications

| Required performance | Applications | Tolerance class |

|---|---|---|

| High acccuracy in runout is required for rolling elements | Machine tool spindles | Class 5, Class 4, Class 2 |

| Magnetic disc spindles for computers | Class 5, Class 4, Class 2 | |

| High speed rotation | Dental spindles | Class 2 |

| Jet engine spindles | Class 5, Class 4 |

High precision bearing applications - Ball & Roller Bearings Catalog

2. Bearing fits and bearing internal clearance

1) Bearing fits

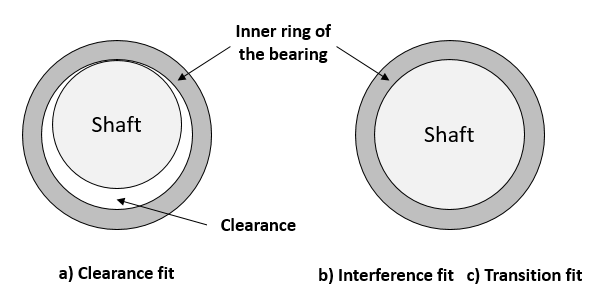

"Bearing fit" is what we call the relationship between the bore diameter of the bearing inner ring and the shaft diameter, or the relationship between the outside diameter of the bearing outer ring and the bore diameter of the housing. Below is an explanation of the types of fit, taking as an example the relationship between the bearing inner ring and the shaft (see Figure 2).

a) Clearance fit

The shaft diameter is smaller than the bore diameter of the inner ring, and even after mounting the inner ring on the shaft there is a clearance between them. Bearing mounting is simple.

b) Interference fit

The shaft diameter is larger than the bore diameter of the inner ring, and the bearing is firmly locked in place on the shaft. This, however, can make it difficult to mount the bearing on the shaft, so consideration needs to be given to the mounting method.

c) Transition fit

This is somewhere between the clearance fit and the interference fit.

Fig. 2: Bearing fits

Fig. 2: Bearing fits

Based on the load direction and conditions, a suitable "fit" should be selected (see Table 6).

Table 6: Load direction/conditions and fit

| Rotation pattern |  Inner ring: rotating Inner ring: rotatingOuter ring: stationary |

Inner ring: stationary Inner ring: stationaryOuter ring: rotating |

|

|---|---|---|---|

| Direction of load |  Stationary Stationary |

Rotating Rotating(Rotating with outer ring) |

|

| Load conditions | Rotating inner ring load | ||

| Stationary outer ring load | |||

| Fit | Inner ring and shaft | Interference fit necessary | |

| Outer ring and housing | Clearance fit acceptable | ||

Load characteristics and fits - Ball & Roller Bearings Catalog

Please check out the next column for more detailed advice on fits.

How to select fit - Ball & Roller Bearings Catalog

Recommended fits - Ball & Roller Bearings Catalog

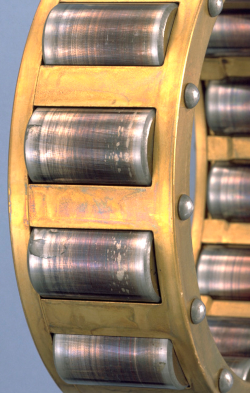

N.B.: Making the wrong decision regarding clearance fit can result in circumferential relative sliipping (see Figure 3) on the fitting surface (the mounting surface between the bearing and the shaft or housing) and damage the bearing. For this reason, it is important to take care when deciding on the fits.

Fig. 3: Circumferential slipping on the bore surface of the bearing inner ring (also known as "creeping")

Fig. 3: Circumferential slipping on the bore surface of the bearing inner ring (also known as "creeping")

2) Internal clearance

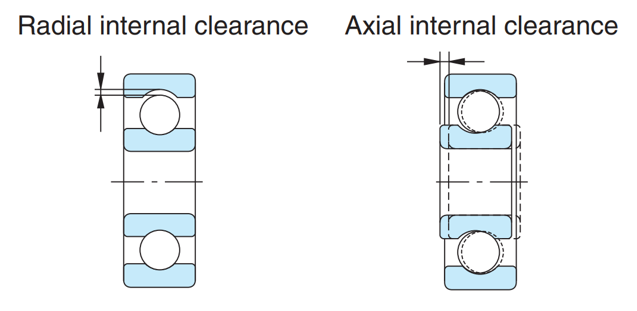

"Bearing internal clearance" is defined as the total distance either inner or outer ring can be moved when the other ring is fixed. Internal clearance can be either radial or axial (see Figure 4).

Fig. 4: Internal clearance

Fig. 4: Internal clearance

The bearing internal clearance has a significant effect on its performance, so it is important to select a bearing with the right internal clearance for the machine usage conditions.

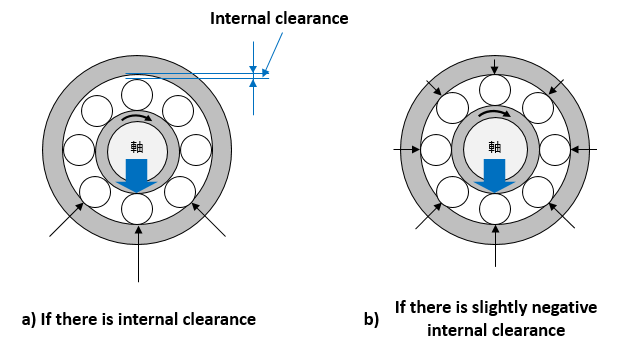

Taking the example of a radial bearing, we will explain about the effect of the internal clearance on rolling element load and fatigue life.

- a) If there is an internal clearance, several rolling elements located near the direction of the load will come in contact with the inner and outer rings, causing a load to be placed. However, there is a clearance at the rolling elements on the opposite side of the load direction, and no load is applied [see Figure 5a) ].

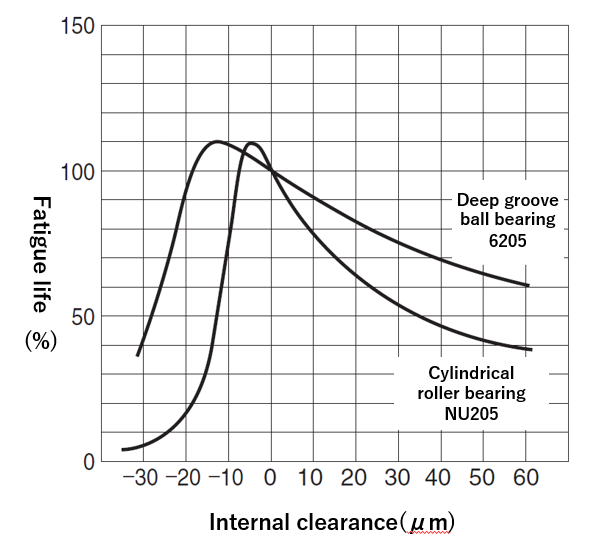

- b) If there is a slightly negative internal clearance, a greater number of rolling elements will come in contact with the inner and outer rings (see Figure 5b), dispersing the load that was placed on more rolling elements. This creates the longest bearing fatigue life. However, if the internal clearance drops far below 0, the load put on the rolling elements will become too heavy, causing significant shortening of fatigue life (see Figure 6).

Fig. 5: Loads placed on rolling elements due to internal clearance

Fig. 5: Loads placed on rolling elements due to internal clearance

Taking the fatigue life when the internal clearance is 0 μm as being 100%

( 1mm=1,000μm )

Fig. 6: The relationship between internal clearance and fatigue life

How to select the internal clearance

The bearing internal clearance should be selected in consideration of the "amount of reduction in clearance" from the clearance when rotating under a load while mounted in the machine (called the "operating clearance") due to such factors as "fit" and "the bearing internal temperature difference." Check the following about the internal clearance standard values broken down by bearing type and specifications as well as how to determine operating clearance, and .

How to determine operating clearance - Ball & Roller Bearings Catalog

Bearing internal clearance by type and bearing bore diameter - Ball & Roller Bearings Catalog

Conclusion

In Part 4, we explained about bearing limiting speed, running accuracy and fits, as measures for whether the bearing type you select was appropriate.

- You should select a bearing with a limiting speed that is higher than the rotational speed in accordance with the operating speed of the machine.

- Bearings of class 5 or higher are required for a precise running accuracy and a higher rotational speed.

- Select the best bearing "fit" based on the load direction and conditions.

- Select the bearing internal clearance based on the operating clearance.