Bearing Trivia

Bearing Trivia for Beginners: "Fits"

- Bearing Trivia for Beginner

To the readers of Bearing Trivia,

Thank you very much for your continued interest in our Bearing Trivia columns.

My name is Mr. W, and I'm in charge of editing the Bearing Trivia columns.

In order to make these entries easy to understand for a general readership, when editing them I deliberately limit them to the necessary basics and cut out any content deemed to be too detailed.

But there are actually times when I think "I really want them to know more about this!"

So this time, I'd like to introduce one of those topics, "Fits," in the form of a "Bearing Trivia for Beginners: Fits"

1. What's a "fit"?

When you learn about bearings or when you actually select a bearing, you will often see the term "fit." But for those of you who don't know a lot about bearings, you're probably quite confused when you see this word, right?

In "How to Select the Right Bearing (Part 4)," we explained the "bearing fits" as follows: "bearing fits"

"Bearing fits" is what we call the relationship between the bore diameter of the bearing inner ring and the shaft diameter, or the relationship between the outside diameter of the bearing outer ring and the inside diameter of the housing. Here we will explain the types of fit, taking as an example the relationship between the bearing inner ring and the shaft.

To put this simply, it's:

The way that the shaft and the hole are combined, or the relationship between them

But I get the feeling this is still somewhat difficult to understand.

So let's interpret "fit" using the relationship between the shaft and the hole.

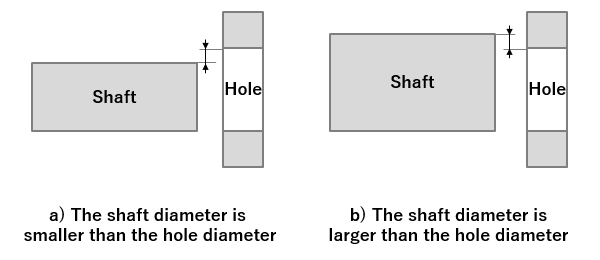

The relationship between the shaft and the hole may be:

the "shaft diameter" being smaller than the "hole diameter" (see Figure 1-a); or

the "shaft diameter" being larger than the "hole diameter" (see Figure 1-b).

Fig. 1: The relationship between the shaft and the hole

This relationship is called the "fit."

2. Bearing fits

Why do bearings have "fit" when the shaft diameter is smaller than or larger than the bearing bore diameter?

A bearing is a machine component that rotates.

For this reason, the usage conditions vary based on the application when it comes to factors such as:

- How high is the temperature of the bearing when it is rotating?

- Is the bearing going to be frequently mounted or dismounted?

- Is it a requirement that the bearing and shaft be firmly mounted in place?

For this reason, you need to select the "type of fit" best suited to allow the bearing to rotate sufficiently under the bearing usage conditions.

* In reality, there are a variety of other usage conditions that you need to consider. If you are interested, please check out "How to Select the Right Bearing (Part 4)" and JTEKT's Ball & Roller Bearings Catalog.

How to Select the Right Bearing (Part 4): Bearing limiting speed, running accuracy and fits

Allow us to explain about three types of fit and the differences among them.

3. The types of fits

I mentioned above that there are different types of fits, but what are they specifically? Why not learn more about these different types of fits?

3-1. Clearance fits

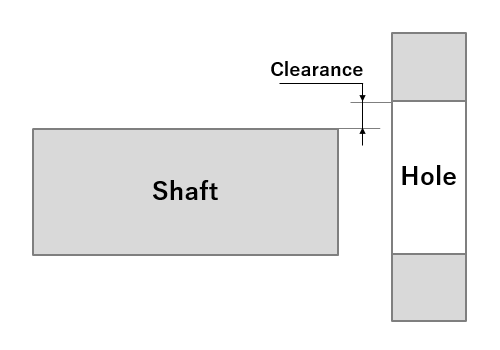

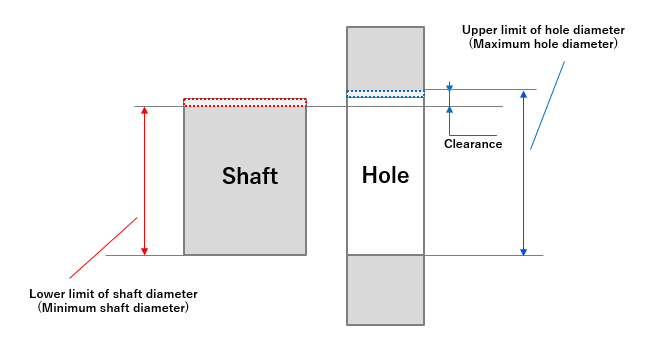

The fit when the shaft diameter is smaller than the bore diameter is called a "clearance fit."

In this situation, the difference between the shaft diameter and the bore diameter is called the "clearance" (see Figure 2).

Fig. 2: A clearance fit

When the shaft and hole are assembled, there is, at all times, a clearance between the shaft and the hole, and both mounting and dismounting can be easily performed.

A typical example of a case where a clearance fit would be appropriate is a "free side bearing" to prevent thermal expansion of the shaft. It is also used in situations where the bearings need mounting and dismounting frequently.

3-2. Interference fit

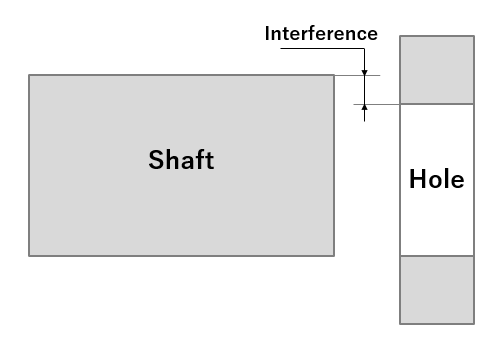

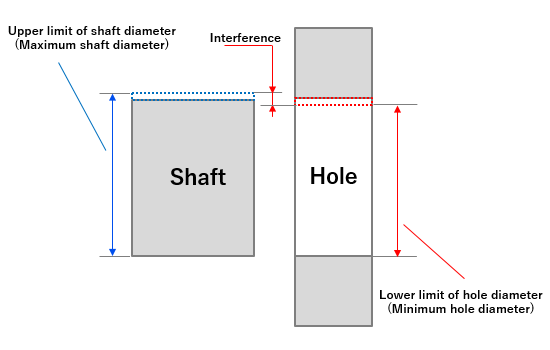

The fit when the shaft diameter is larger than the hole diameter is called an "interference fit."

In this situation, the difference between the shaft diameter and the hole diameter is called the "interference" (see Figure 3).

Fig. 3: An interference fit

When the shaft and the hole are assembled, there is no clearance whatsoever between the hole and the shaft, and the shaft is firmly in place in the hole.

An interference fit firmly sets the shaft in place in the bearing and prevents a sliding motion--or "creep"--of the bearing.

But, because the bearing cannot be mounted easily, it is not appropriate for bearings that need mounting and dismounting frequently.

3-3: Transition fit

A "transition fit" is a fit that is between a clearance fit and an interference fit.

But what does "transition" mean here?

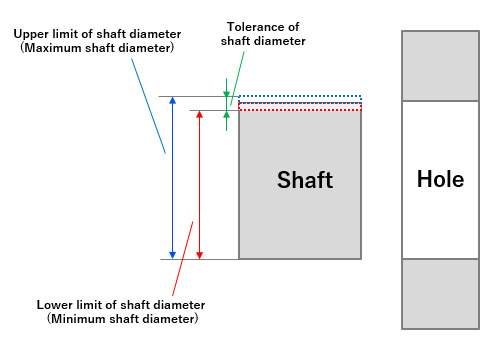

Allow us to explain what "tolerance" means in this context.

Machine components such as bearings, shafts, and housings are finished with a high level of precision, but there will be a deviation in their dimensions after finishing.

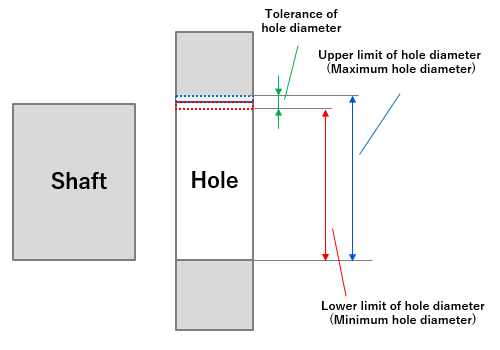

The deviation between the upper and lower limits of dimensions (the difference between the maximum and minimum dimensions) is called the "tolerance" (see Figures 4 and 5).

We will now explain this deviation separately for the shaft and the hole.

Fig. 4: Deviation of shaft diameter

Fig. 5: Deviation of hole diameter

When assembling the shaft and the hole as follows, there will be a "clearance" or an "interference" depending on the finished diameters of the shaft and hole (see Figures 6 and 7).

Fig. 6: When there is a clearance fit

Fig. 7: When there is an interference fit

When the components are assembled in this manner, the fit that could be either a clearance fit or an interference fit is called a "transition fit."

Conclusion

So now you have learned about the concept of a "fit" and about the different types of fit. But you may be surprised to hear that there's actually a whole lot more to learn about fit. There just wasn't enough room in this entry to explain all about things like "the fits between bearings and housings" and "tolerance classes."

A bearing is a machine component with an extremely simple structure. But there is a whole lot of technology and know-how that goes into this simple component, and there are a great many things you need to take into consideration when selecting a bearing.

There are so very many things to learn, and there's always more to it!