Bearing Trivia

How to Select the Right Bearing for Extreme Special Environments (EXSEV Bearings) (Part 3): Bearings with special properties

- #5 How to Select the EXSEV Bearing

In Part 1 of this column, "How to Select the Right Bearing for Extreme Special Environments (EXSEV Bearings)," we explained about the materials and lubricants used in bearings for extreme special environments, while in Part 2, we explained about the specifications of bearings suitable for special environments.

How to Select the Right Bearing for Extreme Special Environments (EXSEV Bearings) (Part 1): Materials and lubricants

How to Select the Right Bearing for Extreme Special Environments (EXSEV Bearings) (Part 2): Bearings for clean, vacuum, high-temperature, or corrosive environments

In this part, we will discuss important points for selecting bearings that require special properties such as non-magnetism, insulation, and high-speed rotation. Note that because ball bearings are often used as rolling bearings for extreme special environments, this column uses ball bearings as an example. We will also show some applications in which the low-torque properties of ceramic bearings are utilized.

1. Specifications of non-magnetic bearings

Some bearings are used in magnetic fields, including those used in superconductivity-related applications, semiconductor manufacturing equipment, and medical examination equipment (see Fig. 1).

Figure 1: MRI (magnetic resonance imaging) that uses non-magnetic bearings

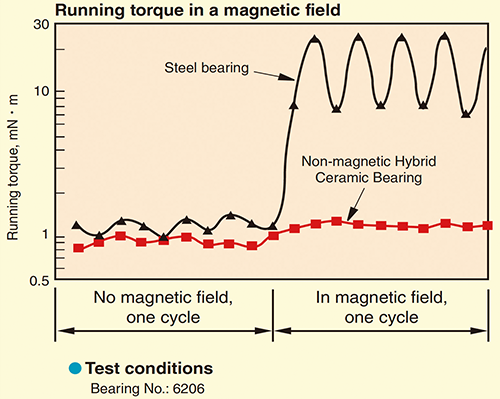

Because using general bearings (*) in such an environment may disturb the magnetic field and cause the running torque of bearings to fluctuate significantly (see Figure 2), the use of non-magnetic bearings is required.

(*) "General bearings" refers to bearings in which high carbon chromium bearing steel is used for the bearing rings and rolling elements.

Figure 2: Running torque of bearings in magnetic fields

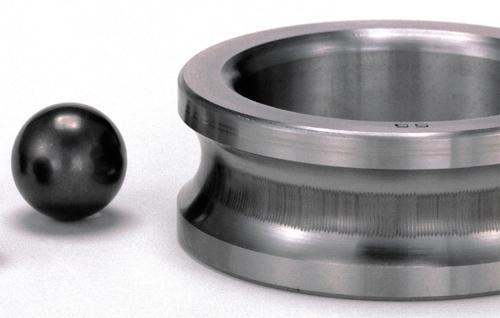

Although beryllium copper has been widely used as a non-magnetic material, its use has waned in recent years due to its containing beryllium, which is a substance of environmental concern. JTEKT provides Hybrid Ceramic Bearings and Full Ceramic Bearings that use bearing rings made with non-magnetic stainless steel and rolling elements made with ceramic materials. Table 1 shows the specifications of Non-magnetic Hybrid Ceramic Bearings.

Table 1: Specifications of Non-magnetic Hybrid Ceramic Bearings

| Non-magnetic Hybrid Ceramic Bearing | ||

| List | Figure 3 | |

| Feature | Material | Non-magnetic stainless steel |

| Lubrication | Polymeric solid lubricant | |

| Outer ring | Non-magnetic stainless steel | |

| Inner ring | Non-magnetic stainless steel | |

| Ball | Silicon nitride | |

| Cage | Fluorocarbon resin | |

| Shield | None | |

| Lubrication | Lubricant | Fluoropolymer |

| Areas | Cage | |

Figure 3: Non-magnetic Hybrid Ceramic Bearing

See the following for details on non-magnetic bearings.

Non-magnetic bearings

2. Specifications of insulating bearings

One type of damage facing bearings used in electric motors and generators is called "electric pitting". Electric pitting refers to the damage that occurs when an electric current passes through a bearing while in operation, generating sparks between the raceway and rolling elements through a very thin oil film, resulting in partial melting of the surfaces where contact is made (see Figure 4).

Figure 4: Electric pitting on bearing

Available countermeasures for electric pitting include providing a bypass that prevents current from passing through the bearing, or using an insulating bearing that prevents the bearing itself from conducting current. Because ceramic materials feature excellent insulation properties, Hybrid Ceramic Bearings with ceramic rolling elements can be used as insulating bearings (see Figure 5).

Figure 5: Insulating bearing (Hybrid Ceramic Bearing)

See the following for details on insulated bearings.

Insulating bearings

3. Specifications of high-speed bearings

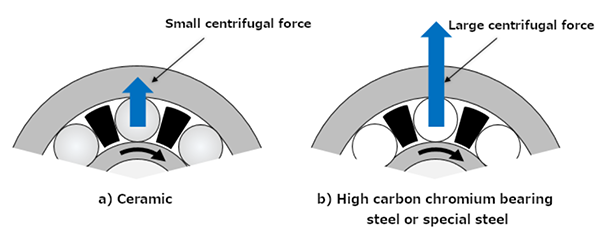

Hybrid Ceramic Bearings, which use ceramic rolling elements with a density lower than that of bearing steel, are suitable for use as high-speed bearings. The lighter mass of the rolling elements reduces the centrifugal force generated by the rolling elements during bearing rotation and the slippage caused by gyroscopic moment (see Figure 6).

Figure 6: Centrifugal force of the rolling elements

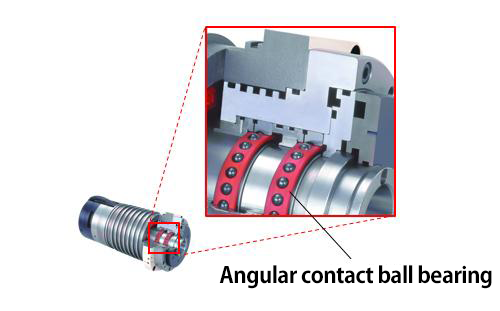

Thanks to their excellent high-speed rotation properties, Hybrid Ceramic Bearings are used in the spindles of many machine tools (see Figures 7 and 8).

Figure 7: Machine tool spindle

Figure 8: Bearing for machine tool spindles (Hybrid Ceramic Bearing)

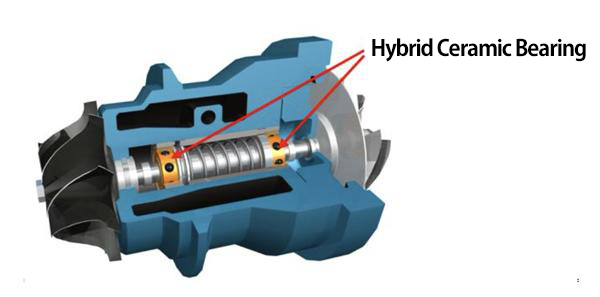

Hybrid Ceramic Bearings are also used for automobile turbochargers (see Figures 9 and 10).

Figure 9: Turbocharger

Figure 10: Turbocharger bearings (Hybrid Ceramic Bearings)

See the following for details on high-speed bearings.

High-speed bearings

4. Low-torque properties of ceramic bearings

We explained about ceramic bearings used in special environments or when special properties are required. We will also show some applications in which the low-torque (rotation with less force) properties of ceramic bearings are utilized.

1) Skateboard bearings

Because skateboard bearings must rotate easily and smoothly while responding to the skater's sensitivity and feeling, the excellent low-torque properties of ceramic bearings are used to meet these requirements. This results in a bearing that enables higher speeds, higher jumps, and the more effective pulling off of tricks.

Figure 11: Skateboard bearing (Hybrid Ceramic Bearing)

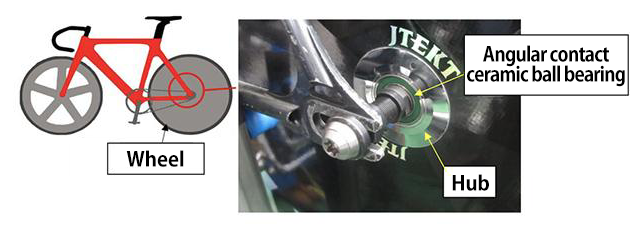

2) Racing bicycle

Wheels are a key component of racing bicycles and using Hybrid Ceramic Bearings for those wheels (see Figures 12 and 13) enhances speed performance and provides a more comfortable ride.

Figure 12: Racing bicycle wheel

Figure 13: Hybrid Ceramic Bearing

Contributing to the World's Best Riding in 2021! Development of a Bearing for Racing Bicycle Wheels

5. Conclusion

In this part, we discussed important points for selecting bearings that require special properties such as non-magnetism, insulation, and high-speed rotation.

| 1) | When selecting non-magnetic bearings, select Hybrid Ceramic Bearings or Full Ceramic Bearings that use bearing rings made with non-magnetic stainless steel and rolling elements made with ceramic materials. |

| 2) | Hybrid Ceramic Bearings, in which ceramic materials with excellent insulating properties are used for the rolling elements, are suitable for use as insulating bearings. |

| 3) | Hybrid Ceramic Bearings, in which ceramic materials are used for the rolling elements in order to reduce the centrifugal force generated by the rolling elements and the slippage caused during high-speed rotation, are suitable for use as high-speed bearings. |

| 4) | Ceramic bearings are also suitable for applications that require low-torque (rotation with less force) properties. |

JTEKT also offers a selecting tool for bearings for extreme special environments.

Selecting tool for bearings for extreme special environments

If you have any technical questions regarding bearings for extreme special environments, or opinions/thoughts on these "Bearing Trivia" pages, please feel free to contact us using the following form.