The term "residual clearance" is defined as the original clearance decreased owing to expansion or contraction of a raceway due to fitting, when the bearing is mounted in the shaft and housing.

The term "effective clearance" is defined as the residual clearance decreased owing to dimensional change arising from temperature differentials within the bearing.

The term "operating clearance" is defined as the internal clearance present while a bearing mounted in a machine is rotating under a certain load, or, the effective clearance increased due to elastic deformation arising from bearing loads.

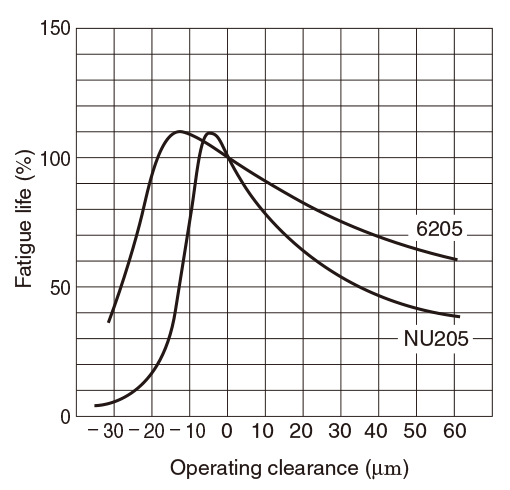

As illustrated in Fig. 10-2, bearing fatigue life is longest when the operating clearance is slightly negative.

However, as the operating clearance becomes more negative, the fatigue life shortens remarkably.

Thus it is recommended that bearing internal clearance be selected such that the operating clearance is slightly positive.

Fig. 10-2 Relationship between operating clearance and fatigue life

It is important to take specific operating conditions into consideration and select a clearance suitable for the conditions.

For example, when high rigidity is required, or when the noise must be minimized, the operating clearance must be reduced. On the other hand, when high operating temperature is expected, the operating clearance must be increased.