Bearings whose inner and outer rings comprise either a rib or loose rib can accommodate a certain magnitude of axial load, as well as radial load. In such cases, axial load capacity is controlled by the condition of rollers, load capacity of rib or loose rib, lubrication, rotational speed etc.

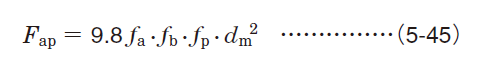

For certain special uses, a design is available to accommodate very heavy axial loads. In general, axial loads allowable for cylindrical roller bearings can be calculated using the following equation, which are based on empirical data.

Table 5-11 Values of coefficient determined from loading condition ƒa

| Loading condition | ƒa |

|---|---|

| Continuous loading | 1 |

| Intermittent loading | 2 |

| Instantaneous loading | 3 |

Table 5-12 Values of coefficient determined from bearing diameter series ƒb

| Diameter series | ƒb |

|---|---|

| 9 | 0.6 |

| 0 | 0.7 |

| 2 | 0.8 |

| 3 | 1.0 |

| 4 | 1.2 |

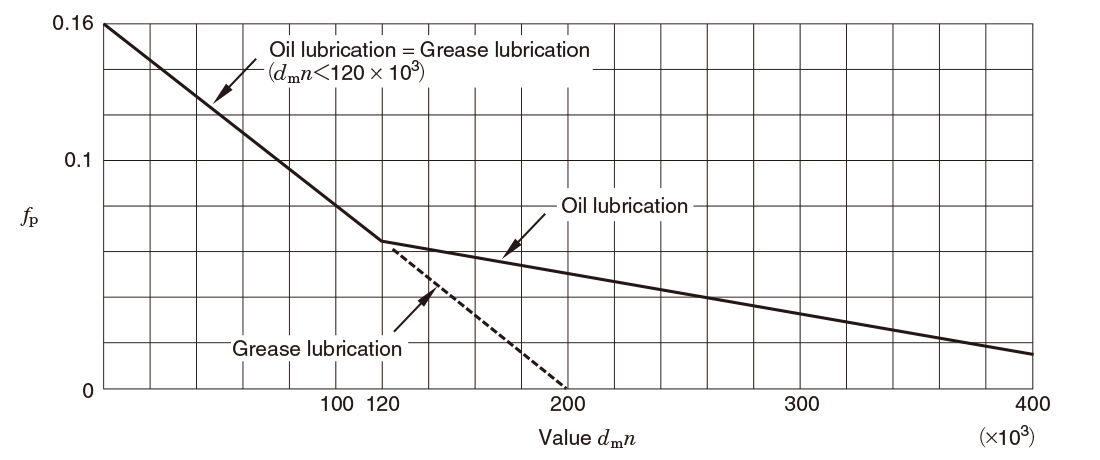

Fig. 5-13 Relationship between coefficient for rib surface pressure ƒp and value dmn

(n : rotational speed, min-1)