Lubrication is one of the most important factors determining bearing performance. The suitability of the lubricant and lubrication method have a dominant influence on bearing life.

Functions of lubrication :

- To lubricate each part of the bearing, and to reduce friction and wear

- To carry away heat generated inside bearing due to friction and other causes

- To cover rolling contact surface with the proper oil film in order to prolong bearing fatigue life

- To prevent corrosion and contamination by dirt

Bearing lubrication is classified broadly into two categories: grease lubrication and oil lubrication. Table 12-1 makes a general comparison between the two.

Table 12-1 Comparison between grease and oil lubrication

| Item | Grease | Oil |

|---|---|---|

| Sealing device | Easy | Slightly complicated and special care required for maintenance |

| Lubricating ability | Good | Excellent |

| Rotation speed | Low/medium speed | Applicable at high speed as well |

| Replacement of lubricant | Slightly troublesome | Easy |

| Life of lubricant | Relatively short | Long |

| Cooling effect | No cooling effect | Good (circulation is necessary) |

| Filtration of dirt | Difficult | Easy |

12-1-1 Grease lubrication

Grease lubrication is widely applied since there is no need for replenishment over a long period once grease is filled, and a relatively simple structure can suffice for the lubricant sealing device.

There are two methods of grease lubrication. One is the closed lubrication method, in which grease is filled in advance into shielded/sealed bearing; the other is the feeding method, in which the bearing and housing are filled with grease in proper quantities at first, and refilled at a regular interval via replenishment or replacement.

Devices with numerous grease inlets sometimes employ the centralized lubricating method, in which the inlets are connected via piping and supplied with grease collectively.

1) Amount of grease

In general, grease should fill approximately one-third to one-half the inside space, though this varies according to structure and inside space of housing.

It must be borne in mind that excessive grease will generate heat when churned, and will consequently alter, deteriorate, or soften.

When the bearing is operated at low speed, however, the inside space is sometimes filled with grease to two-thirds to full, in order to

2) Replenishment/replacement of grease

The method of replenishing/replacing grease depends largely on the lubrication method. Whichever method may be utilized, care should be taken to use clean grease and to keep dirt or other foreign matter out of the housing.

In addition, it is desirable to refill with grease of the same brand as that filled at the start.

When grease is refilled, new grease must be injected inside bearing.

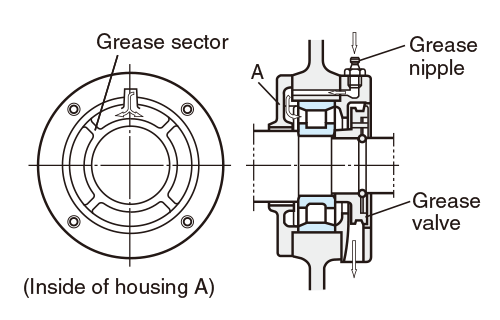

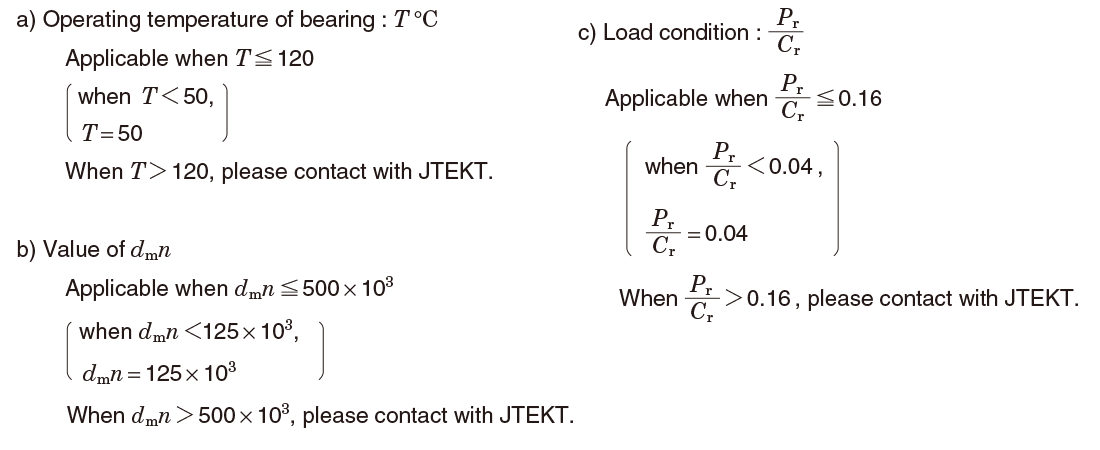

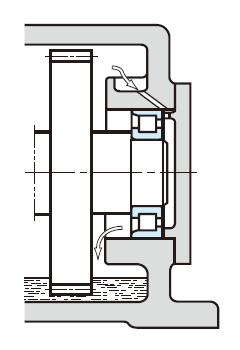

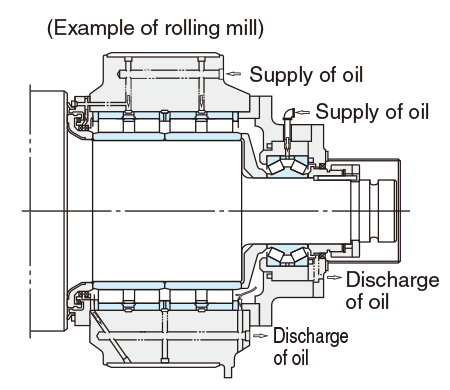

Fig. 12-1 gives one example of a feeding method.

Fig. 12-1 Example of grease feeding method (using grease sector)

In the example, the inside of the housing is divided by grease sectors. Grease fills one sector, then flows into the bearing.

On the other hand, grease flowing back from the inside is forced out of the bearing by the centrifugal force of the grease valve.

When the grease valve is not used, it is necessary to enlarge the housing space on the discharge side to store old grease.

The housing is uncovered and the stored old grease is removed at regular intervals.

3) Grease feeding interval

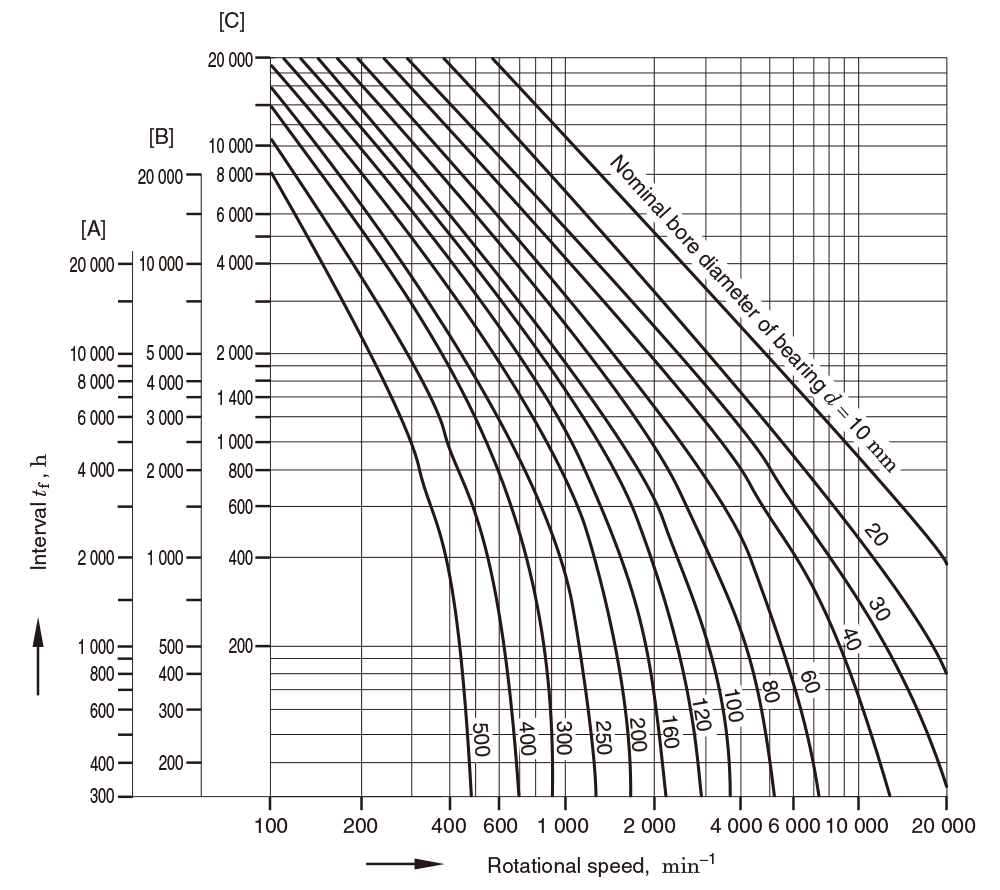

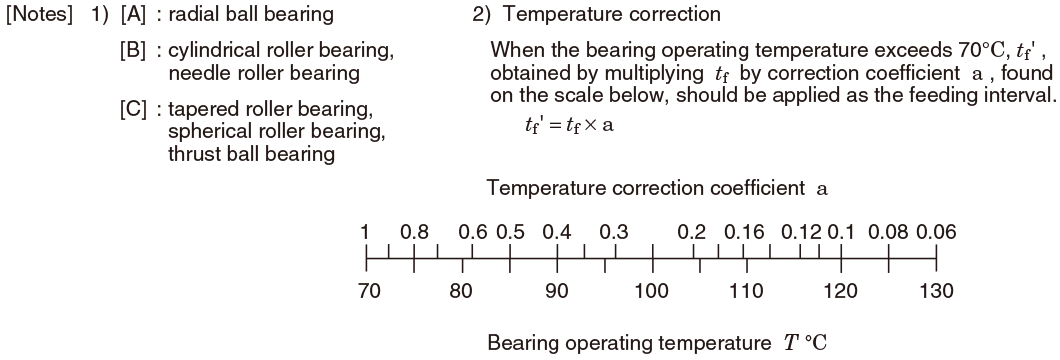

In normal operation, grease life should be regarded roughly as shown in Fig. 12-2, and replenishment/replacement should be carried out accordingly.

Fig. 12-2 Grease feeding interval

4) Grease life in shielded/sealed ball bearing

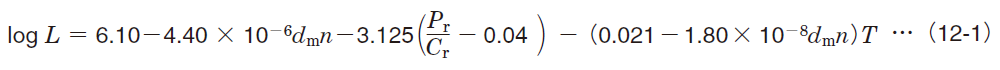

Grease life can be estimated by the following equation when a single-row deep groove ball bearing is filled with grease and sealed with shields or seals.

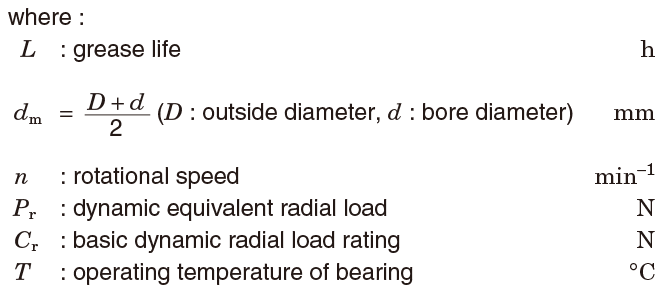

The conditions for applying equation (12-1) are as follows :

12-1-2 Oil lubrication

Oil lubrication is usable even at high speed rotation and somewhat high temperature, and is effective in reducing bearing vibration and noise. Thus oil lubrication is used in many cases where grease lubrication does not work. Table 12-2 shows major types and methods of oil lubrication.

Table 12-2 Type and method of oil lubrication

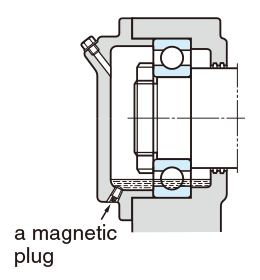

① Oil bath

- Simplest method of bearing immersion in oil for operation.

- Suitable for low/medium speed.

- Oil level gauge should be furnished to adjust the amount of oil.

(In the case of horizontal shaft)

About 50 % of the lowest rolling element should be immersed.

(In the case of vertical shaft)

About 70 to 80 % of the bearing should be immersed. - It is better to use a magnetic plug to prevent wear iron particles from dispersing in oil.

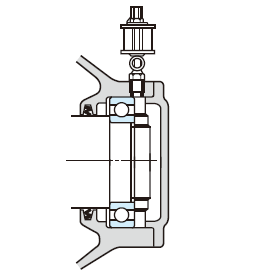

② Oil drip

- Oil is dripped with an oiling device, and the inside of the housing is filled with oil mist by the action of rotating parts. This method has a cooling effect.

- Applicable at relatively high speed and up to medium load.

- In general, 5 to 6 drops of oil are utilized per minute.

(It is difficult to adjust the dripping in 1mL/h or smaller amounts.) - It is necessary to prevent too much oil from being accumulated at the bottom of housing.

③ Oil splash

- This type of lubrication method makes use of a gear or simple flinger attached to shaft in order to splash oil. This method can supply oil for bearings located away from the oil tank.

- Usable up to relatively high speed.

- It is necessary to keep oil level within a certain range.

- It is better to use a magnetic plug to prevent wear iron particles from dispersing in oil.

It is also advisable to set up a shield or baffle board to prevent contaminants from entering the bearing.

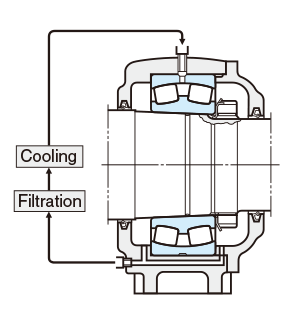

④ Forced oil circulation

- This method employs a circulation-type oil supply system.

Supplied oil lubricates inside of the bearing, is cooled and sent back to the tank through an oil escape pipe. The oil, after filtering and cooling, is pumped back. - Widely used at high speeds and high temperature conditions.

- It is better to use an oil escape pipe approximately twice as thick as the oil supply pipe in order to prevent too much lubricant from gathering in housing.

- Required amount of oil : see Remark 1.

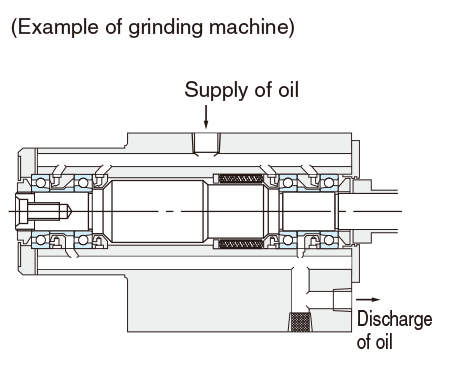

⑤ Oil jet lubrication

- This method uses a nozzle to jet oil at a constant pressure (0.1 to 0.5MPa), and is highly effective in cooling.

- Suitable for high speed and heavy load.

- Generally, the nozzle (diameter 0.5 to 2 mm) is located 5 to 10 mm from the side of a bearing.

When a large amount of heat is generated, 2 to 4 nozzles should be used. - Since a large amount of oil is supplied in the jet lubrication method, old should be discharged with an oil pump to prevent excessive residual oil.

- Required amount of oil : see Remark 1.

⑥ Oil mist lubrication (spray lubrication)

- This method employs an oil mist generator to produce dry mist (air containing oil in the form of mist). The dry mist is continuously sent to the oil supplier, where the mist is turned into a wet mist (sticky oil drops) by a nozzle set up on the housing or bearing, and is then sprayed onto bearing.

- This method provides and sustains the smallest amount of oil film necessary for lubrication, and has the advantages of preventing oil contamination, simplifying bearing maintenance, prolonging bearing fatigue life, reducing oil consumption etc.

- Required amount of mist : see Remark 2.

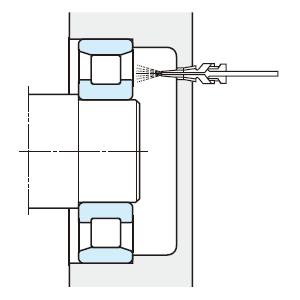

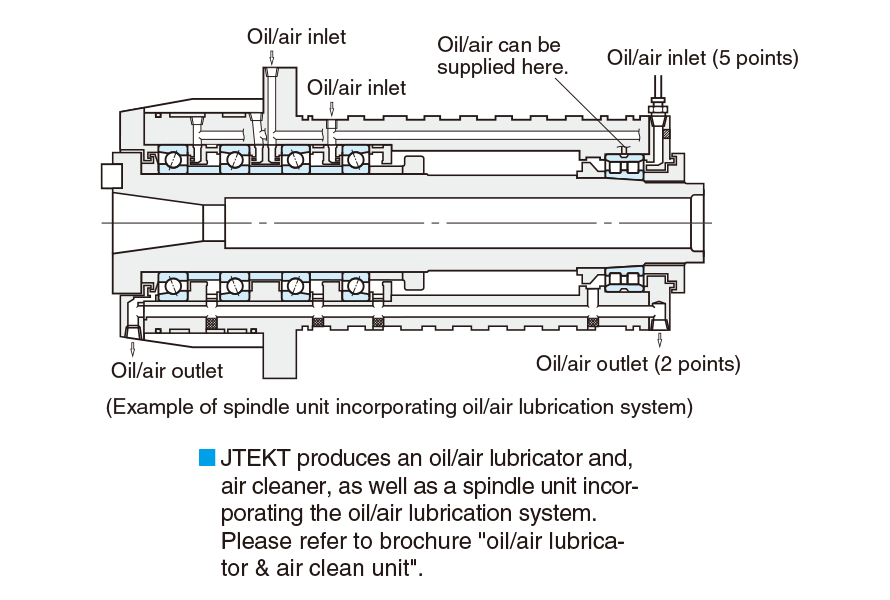

⑦ Oil/air lubrication

- A proportioning pump sends forth a small quantity of oil, which is mixed with compressed air by a mixing valve. The admixture is supplied continuously and stably to the bearing.

- This method enables quantitative control of oil in extremely small amounts, always supplying new lubricating oil. It is thus suitable for machine tools and other applications requiring high speed.

- Compressed air and lubricating oil are supplied to the spindle, increasing the internal pressure and helping prevent dirt, cutting-liquid, etc. from entering. As well, this method allows the lubricating oil to flow through a feeding pipe, minimizing atmospheric pollution.

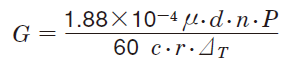

Remark 1Required oil supply in forced oil circulation ; oil jet lubrication methods

Values of friction coefficientμ

| Bearing type | μ |

|---|---|

| Deep groove ball bearing | 0.0010 - 0.0015 |

| Angular contact ball bearing | 0.0012 - 0.0020 |

| Cylindrical roller bearing | 0.0008 - 0.0012 |

| Tapered roller bearing | 0.0017 - 0.0025 |

| Spherical roller bearing | 0.0020 - 0.0025 |

The values obtained by the above equation show quantities of oil required to carry away all the generated heat, with heat release not taken into consideration.

In reality, the oil supplied is generally half to two-thirds of the calculated value.

Heat release varies widely according to the application and operating conditions.

To determine the optimum oil supply, it is advised to start operating with two-thirds of the calculated value, and then reduce the oil gradually while measuring the operating temperature of bearing, as well as the supplied and discharged oil.

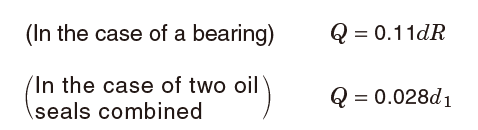

Remark 2Notes on oil mist lubrication

1)Required amount of mist (mist pressure : 5 kPa)

In the case of high speed(dmn≧40万)it is necessary to increase the amount of oil and heighten the mist pressure.

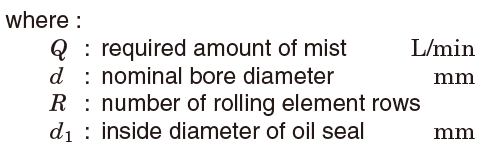

2) Piping diameter and design of lubrication hole/groove

When the flow rate of mist in piping exceeds 5 m/s, oil mist suddenly condenses into an oil liquid.

Consequently, the piping diameter and dimensions of the lubrication hole/groove in the housing should be designed to keep the flow rate of mist, obtained by the following equation, from exceeding 5 m/s.

3) Mist oil

Oil used in oil mist lubrication should meet the following requirements.

- ability to turn into mist

- has high extreme pressure resistance

- good heat/oxidation stability

- rust-resistant

- unlikely to generate sludge

- superior demulsifier

(Oil mist lubrication has a number of advantages for high speed rotation bearings. Its performance, however, is largely affected by surrounding structures and bearing operating conditions.

If contemplating the use of this method, please contact with JTEKT for advice based on JTEKT long experience with oil mist lubrication.)