12-2-1 Grease

Grease is made by mixing and dispersing a solid of high oil-affinity (called a thickener) with lubricant oil (as a base), and transforming it into a semi-solid state.

As well, a variety of additives can be added to improve specific performance.

(1) Base oil

Mineral oil is usually used as the base oil for grease. When low temperature fluidity, high temperature stability, or other special performance is required, diester oil, silicon oil, polyglycolic oil, fluorinated oil, or other synthetic oil is often used.

Generally, grease with a low viscosity base oil is suitable for applications at low temperature or high rotation speed; grease with high viscosity base oils are suitable for applications at high temperature or under heavy load.

(2) Thickener

Most greases use a metallic soap base such as lithium, sodium, or calcium as thickeners. For some applications, however, non-soap base thickeners (inorganic substances such as bentone, silica gel, and organic substances such as urea compounds, fluorine compounds) are also used.

In general, the mechanical stability, bearing operating temperature range, water resistance, and other characteristics of grease are determined by the thickener.

(Lithium soap base grease)

Superior in heat resistance, water resistance and mechanical stability.

(Calcium soap base grease)

Superior in water resistance; inferior in heat resistance.

(Sodium soap base grease)

Superior in heat resistance; inferior in water resistance.

(Non-soap base grease)

Superior in heat resistance.

Table 12-3 Characteristics of respective greases

| Lithium grease | Calcium grease (cup grease) | Sodium grease (fiber grease) | Complex base grease | Non-soap base grease | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thickener | Lithium soap | Calcium soap | Sodium soap | Lithium complex soap | Calcium complex soap | Bentone | Urea compounds | Fluorine compounds | ||

| Base oil | Mineral oil | Synthetic oil(diester oil) | Synthetic oil(silicon oil) | Mineral oil | Mineral oil | Mineral oil | Mineral oil | Mineral oil | Mineral/synthetic oil | Synthetic oil |

| Dropping point(℃) | 170 to 190 | 170 to 230 | 220 to 260 | 80 to 100 | 160 to 180 | 250 or higher | 200 to 280 | - | 240 or higher | 250 or higher |

| Operating temperature range(℃) | -30 to +120 | -50 to +130 | -50 to +180 | -10 to +70 | 0 to +110 | -30 to +150 | -10 to +130 | -10 to +150 | -30 to +150 | -40 to +250 |

| Rotation speed range | Medium to high | High | Low to medium | Low to medium | Low to high | Low to high | Low to medium | Medium to high | Low to high | Low to medium |

| Mechanical stability | Excellent | Good to excellent | Good | Fair to good | Good to excellent | Good to excellent | Good | Good | Good to excellent | Good |

| Water resistance | Good | Good | Good | Good | Bad | Good to excellent | Good | Good | Good to excellent | Good |

| Pressure resistance | Good | Fair | Bad to fair | Fair | Good to excellent | Good | Good | Good to excellent | Good to excellent | Good |

| Remarks | Most widely usable for various rolling bearings. | Superior low temperature and friction characteristics. Suitable for bearings for measuring instruments and extra-small ball bearings for small electric motors. | Superior high and low temperature characteristics. | Suitable for applications at low rotation speed and under light load. Not applicable at high temperature. |

Liable to emulsify in the presence of water. Used at relatively high temperature. |

Superior mechanical stability and heat resistance. Used at relatively high temperature. |

Superior pressure resistance when extreme pressure agent is added. Used in bearings for rolling mills. |

Suitable for applications at high temperature and under relatively heavy load. | Superior water resistance, oxidation stability, and heat stability. Suitable for applications at high temperature and high speed. |

Superior chemical resistance and solvent resistance. Usable at up to 250℃. |

(3) Additives

Various additives are selectively used to serve the respective purposes of grease applications.

- Extreme pressure agents

When bearings must tolerate heavy or impact loads. - Oxidation inhibitors

When grease is not refilled for a long period. Structure stabilizers, rust preventives, and corrosion inhibitors are also used.

(4) Consistency

Consistency, which indicates grease hardness, is expressed as a figure obtained, in accordance with ASTM (JIS), by multiplication by 10 the depth (in mm) to which the coneshaped metallic plunger penetrates into the grease at 25℃ by deadweight in 5 seconds. The softer the grease, the higher the figure. Table 12-4 shows the relationships between the NLGI scales and ASTM (JIS) penetration indexes, service conditions of grease. (NLGI : National Lubricating Grease Institute)

Table 12-4 Grease consistency

| NLGI scale | AASTM (JIS) penetration index (25℃, 60 mixing operations) | Service conditions/ applications |

|---|---|---|

| 0 | 355 - 385 | For centralized lubricating |

| 1 | 310 - 340 | For centralized lubricating, at low temperature |

| 2 | 265 - 295 | For general use |

| 3 | 220 - 250 | For general use, at high temperature |

| 4 | 175 - 205 | For special applications |

(5) Mixing of different greases

Since mixing of different greases changes their properties, greases of different brands should not be mixed.

If mixing cannot be avoided, greases containing the same thickener should be used. Even if the mixed greases contain the same thickener, however, mixing may still produce adverse effects, due to difference in additives or other factors.

Thus it is necessary to check the effects of a mixture in advance, through testing or other methods.

Table 12-5 Typical examples of standard grease for JTEKT bearings

| Grease name | Thickener | Base oil | Appearance | Consistency 60W | NLGI scale | Operating temperature range ℃ | Application examples | ||

|---|---|---|---|---|---|---|---|---|---|

| Unworked | Worked | ||||||||

| Alvania 2 | Lithium | Mineral oil | Grayish brown | 276 | 275 | 2 | -10 - 100 | Automobile | Steering column |

| Raremax AF-I | Urea | Mineral oil | Pale yellow, viscous | - | 300 | 1-22) | 0 - 150 | Wheel (hub unit) | |

| FS841 | Fluororesin | Fluorosilicone oil | White | - | 290 | 2 | -40 - 220 | Fan coupling | |

| Sunlight 2 | Lithium | Mineral oil | Yellowish brown | - | 280 | 2 | -10 - 100 | Universal joint (shell type), steering joint | |

| Unirex N3 | Lithium complex | Mineral oil | Green | - | 235 | 3 | -10 - 130 | Clutch release | |

| W191 | Urea | PAO1), mineral oil | Pale yellow | 247 | 275 | 2 | -30 - 130 | Water pump bearing | |

| Darina 2 | Microgel | Mineral oil | Amber | - | 280 | 2 | 0 - 150 | Steel production | Conveyor |

| Emalube L | Urea | Mineral oil | Light brown, viscous | - | 350 | 0-1 2) | -10 - 200 | Continuous casting machine | |

| Palmax RBG | Special lithium complex | Mineral oil | Yellow, viscous | - | 300 | 1-2 2) | -10 - 150 | Rolling mill roll neck | |

| 4B grease | Carbon black | Ethyl oil | Black | - | 260 | 2-32) | -30 - 250 | Extra-small/miniature ball bearings | Photocopier (high temperature/conductive),printer (high temperature/conductive) |

| KRYTOX GPL 226 | Fluororesin | Fluorinated oil | - | 280 | 2 | 0 - 250 | Photocopier (high temperature),printer (high temperature) | ||

| Multemp PSNo.2 | Lithium | Mineral oil, ester oil | Pinkish white, viscous | - | 275 | 2 | -40 - 100 | Motor (for low temperatures) | |

| KVC grease | Urea | PAO1)、ester oil | Milkish pink | - | 244 | 3 | -30 - 150 | Motor (for high temperatures), rotary encoder,fan motor (for high temperatures) | |

| SR grease | Lithium | Ester oil | Light brown, viscous | - | 250 | 3 | -40 - 130 | Extra-small/miniature ball bearings,automobile | Motor, stepping motor, fan motor Center bearing (for propeller shafts), steering column |

| KDL grease | Fluororesin (PTFE) | Fluorinated oil | White | - | 260 | 2-32) | -30 - 200 | Semiconductor manufacturing equipment | For high temperatures, for clean environment,for vacuum environment |

| KHD | Lithium | PAO1) | White | - | 199 | 4 | -30 - 120 | For room temperature, for atmosphere | |

| Nerita 2858 | Lithium | Mineral oil (XHVI) | Yellowish brown | - | 279 | 2 | -30 - 100 | Railway rolling stock | Axle journal (ABU) |

| Arapen RB320 | Lithium, calcium | Mineral oil | Yellowish brown | - | 315 | 1 | -30 - 90 | Axle journal (general) | |

| Isoflex NBU15 | Barium complex | Ester oil | Beige | 270 | 280 | 2 | -40 - 100 | Machine tool spindle | |

| Shell Cassida grease RLS2 | Aluminum complex | PAO1) | Transparent | - | 280 | 2 | -20 - 100 | For food machinery | |

| Alvania EP2 | Lithium | Mineral oil | Brown | 282 | 276 | 2 | -10 - 80 | Slewing rim, automobile | Universal joint, king pin thrust bearing |

| Alvania 3 | Lithium | Mineral oil | Brown | 240 | 225 | 3 | -10 - 100 | Agricultural machinery | |

[Notes]

1)PAO:Polyalphaolefin oil

2)The value is within the range specified by the consistency numbers.

12-2-2 Lubricating oil

For lubrication, bearings usually employ highly refined mineral oils, which have superior oxidation stability, rust-preventive effect, and high film strength. With bearing diversification, however, various synthetic oils have been put into use. These synthetic oils contain various additives (oxidation inhibitors, rust preventives, antifoaming agents, etc.) to improve specific properties. Table 12-6 shows the characteristics of lubricating oils.

Mineral lubricating oils are classified by applications in JIS and MIL.

Table 12-6 Characteristics of lubricating oils

| Type of lubricating oil | Highly refined mineral oil | Major synthetic oils | ||||

|---|---|---|---|---|---|---|

| Diester oil | Silicon oil | Polyglycolic oil | Polyphenyl ether oil | Fluorinated oil | ||

| Operating temperature range(℃) | -40 to +220 | -55 to +150 | -70 to +350 | -30 to +150 | 0 to +330 | -20 to +300 |

| Lubricity | Excellent | Excellent | Fair | Good | Good | Excellent |

| Oxidation stability | Good | Good | Fair | Fair | Excellent | Excellent |

| Radioactivity resistance | Bad | Bad | Bad to fair | Bad | Excellent | - |

[Selection of lubricating oil]

The most important criterion in selecting a lubricating oil is whether the oil provides proper viscosity at the bearing operating temperature. Standard values of proper kinematic viscosity can be obtained through selection by bearing type according to Table 12-7 first, then through selection by bearing operating conditions according to Table 12-8.

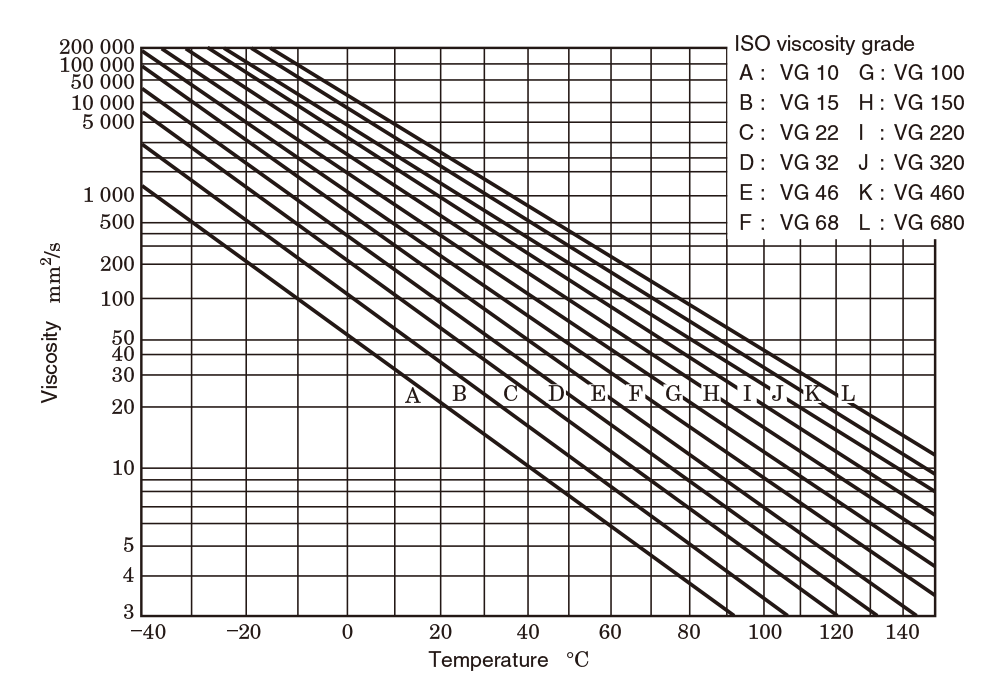

When lubricating oil viscosity is too low, the oil film will be insufficient. On the other hand, when the viscosity is too high, heat will be generated due to viscous resistance. In general, the heavier the load and the higher the operating temperature, the higher the lubricating oil viscosity should be ; whereas, the higher the rotation speed, the lower the viscosity should be. Fig. 12-3 illustrates the relationship between lubricating oil viscosity and temperature.

Table 12-7 Proper kinematic viscosity by bearing type

| Bearing type | Proper kinematic viscosity at operating temperature |

|---|---|

| Ball bearing Cylindrical roller bearing | 13mm2/s or higher |

| Tapered roller bearing Spherical roller bearing | 20mm2/s or higher |

| Spherical thrust roller bearing | 32mm2/s or higher |

Table 12-8 Proper kinematic viscosities by bearing operating conditions

| Operating temperature | dmnvalue | Proper kinematic viscosity (expressed in the ISO viscosity grade or the SAE No.) | |||

|---|---|---|---|---|---|

| Light/normal load | Heavy/impact load | ||||

| -30 to 0℃ | All rotation speeds | ISO VG 15、22、46 | (Refrigerating machine oil) | - | |

| 0 to 60℃ | 300000 or lower | ISO VG 46 | (Bearing oil Turbine oil) | ISO VG 68 | (Bearing oil Turbine oil) |

| SAE 30 | |||||

| 300000 to 600000 | ISO VG 32 | (Bearing oil Turbine oil) | ISO VG 68 | (Bearing oil Turbine oil) | |

| 600000 or higher | ISO VG 7、10、22 | (Bearing oil) | - | ||

| 60 to 100℃ | 300000 or lower | ISO VG 68 | (Bearing oil) | ISO VG 68、100 | (Bearing oil) |

| SAE 30 | |||||

| 300000 to 600000 | ISO VG 32、46 | (Bearing oil Turbine oil) | ISO VG 68 | (Bearing oil Turbine oil) | |

| 600000 or higher | ISO VG 22、32、46 | (Bearing oil Turbine oil Machine oil) | - | ||

| 100 to 150℃ | 300000 or lower | ISO VG 68、100 | (Bearing oil) | ISO VG 100 to 460 | (Bearing oil Gear oil) |

| SAE 30、40 | |||||

| 300000 to 600000 | ISO VG 68 | (Bearing oil Turbine oi) | ISO VG 68、100 | (Bearing oil) | |

| SAE 30 | SAE 30、40 | ||||

[Remarks]

{D:nominal outside diameter(mm)、d:nominal bore diameter(mm)、n:rotational speed(min-1)}

{D:nominal outside diameter(mm)、d:nominal bore diameter(mm)、n:rotational speed(min-1)}- Refer to refrigerating machine oil (JIS K 2211), turbine oil (JIS K 2213), gear oil (JIS K 2219), machine oil (JIS K 2238) and bearing oil (JIS K 2239).

- Please contact with JTEKT if the bearing operating temperature is under −30℃ or over 150℃ .

Fig. 12-3 Relationship between lubricating oil viscosity and temperature (viscosity index :100)