| Codes | descriptions |

|---|

| 68 |

Deep groove ball bearing |

| 69 |

|

| 60 |

|

|

|

(For standard bearing code,

refer to Table 6-1) |

|

| Codes | descriptions |

|---|

| /0.6 |

0.6mm (Bore diameter) |

| 1 |

1 |

| /1.5 |

1.5 |

| 2 |

2 |

| /2.5 |

2.5 |

| 3 |

3 |

|

|

| 9 |

9 |

| 00 |

10 |

| 01 |

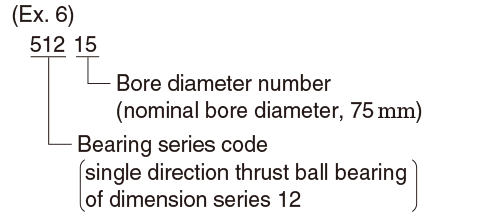

12 |

| 02 |

15 |

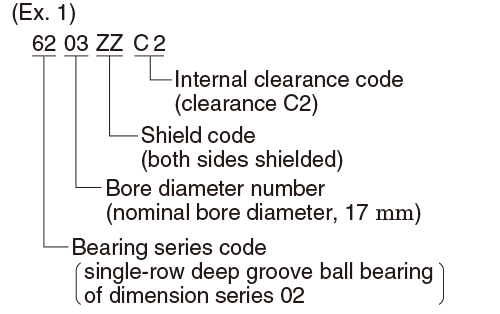

| 03 |

17 |

| 04 |

20 |

| /22 |

22 |

| 05 |

25 |

| /28 |

28 |

| 06 |

30 |

| /32 |

32 |

| 07 |

35 |

|

|

| 96 |

480 |

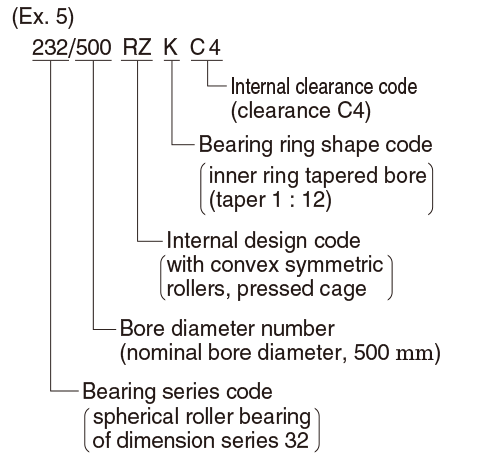

| /500 |

500 |

| /530 |

530 |

|

|

| /2500 |

2500 |

| á Bore diameters (mm) of bearing in the bore diameter range 04 to 96 can be obtained by multiplying their bore diameter number by five. |

|

| Codes | descriptions |

|---|

| Angular contact ball bearing |

| A (omitted) |

30° |

| AC |

25° |

| B |

40° |

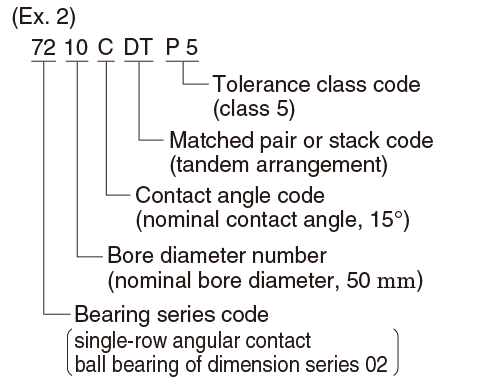

| C |

15° |

| CA |

20° |

| E |

35° |

| Tapered roller bearing |

| B (omitted) |

Less than 17° |

| C |

20° |

| D |

28° 30' |

| DJ |

28° 48' 39" |

|

|

| Codes | descriptions |

|---|

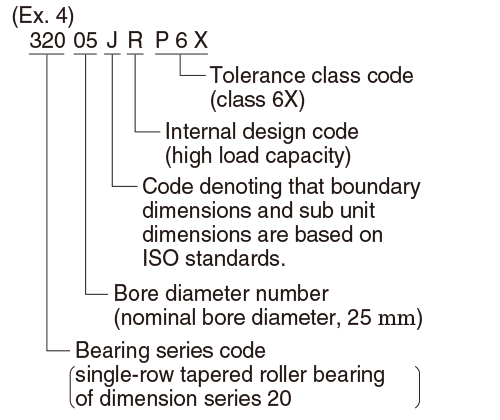

| R |

High load capacity (Deep groove ball bearing, cylindrical roller bearing, tapered roller bearing) |

| G |

Equal stand-out is provided on both sides of the ring of angular contact ball bearing

(In general, C2 clearance is used) |

| GST |

Angular contact ball bearing described above with standard internal clearance provided |

| J |

Tapered roller bearing, whose outer ring width, contact angle and outer ring small inside diameter conform to ISO standards |

| Spherical roller bearings |

| R |

With convex asymmetric rollers and machined cage |

| RH |

With convex symmetric rollers and pressed cage |

| RHA |

With convex symmetric rollers and one-piece machined cage |

| V |

Full complement type ball or roller bearing (with no cage) |

|

| Codes | descriptions |

|---|

| (Shield) |

| Z |

one side Fixed shield |

| ZZ |

both sides Fixed shield |

| ZX |

one side Removable shield |

| ZZX |

both sides Removable shield |

| (Non-contact seal) |

| RU |

one side |

| 2RU |

both sides |

| ZU |

one side |

| 2ZU |

both sides |

| (Contact seal) |

| RS |

one side |

| 2RS |

both sides |

| RK |

one side |

| 2RK |

both sides |

| U |

one side |

| UU |

both sides |

| (Extremely light contact seal) |

| RD |

one side |

| 2RD |

both sides |

|

|

| Codes | descriptions |

|---|

| K |

Inner ring tapered bore provided

(1:12) |

| K30 |

Inner ring tapered bore provided

(1:30) |

| N |

Snap ring groove on outer ring outside surface provided |

| NR |

Snap ring groove and locating snap ring on outer ring outside surface provided |

| NY |

Creep prevention synthetic resin ring on outer ring outside surface provided |

| SG |

Spiral groove on inner ring bore surfaceprovided |

| W |

Lubrication hole and lubrication groove on cylindrical roller bearing outer ring outside surface provided |

| W33 |

Lubrication hole and lubrication groove on spherical roller bearing outer ring outside surface provided |

|

|

| Codes | descriptions |

|---|

| Code not given |

High carbon chrome bearing steel |

| E |

Case carburizing steel |

| F |

Case carburizing steel |

| H |

Case carburizing steel |

| Y |

Case carburizing steel |

| ST |

Stainless steel |

| SH |

Special heat treatment |

| (Dimension stabilizing treatment) |

| S0 |

Up to 150℃ |

| S1 |

Up to 200℃ |

| S2 |

Up to 250℃ |

|

|

| Codes | descriptions |

|---|

| (Angular contact ball bearing) |

| DB |

Back-to-back arrangement |

| DF |

Face-to-face arrangement |

| DT |

Tandem arrangement |

| (Ball bearing) |

| PA |

With outer ring guide cage |

| (Roller bearing) |

| Q3 |

With roller guide cage |

|

|

| Codes | descriptions |

|---|

| (Radial internal clearance for radial bearing) |

| C1 |

Smaller than C2 |

| C2 |

Smaller than standard clearance |

| CN |

Standard clearance |

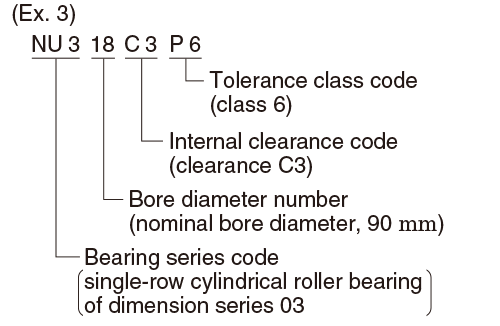

| C3 |

Greater than standard clearance |

| C4 |

Greater than C3 |

| C5 |

Greater than C4 |

| (Radial internal clearance for extra-small/miniature ball bearing) |

| M1 |

0~5μm |

| M2 |

3~8μm |

| M3 |

5~10μm |

| M4 |

8~13μm |

| M5 |

13~20μm |

| M6 |

20~28μm |

| (Radial internal clearance for double-row angular contact ball bearing) |

| CD2 |

Smaller than standard clearance |

| CDN |

Standard clearance |

| CD3 |

Greater than standard clearance |

| (Deep groove ball bearing) |

| CM |

Radial internal clearance for electric |

| CT |

motor bearing |

| NA |

Non-interchangeable cylindrical roller bearing radial internal clearance (C1NA to C5NA) |

| (Preload for angular contact ball bearing) |

| S |

Slight preload |

| L |

Light preload |

| M |

Medium preload |

| H |

Heavy preload |

|

|

| Codes | descriptions |

|---|

| (Spacer width (mm) is affixed to the end of each code.) |

| (Deep groove ball bearing) |

| + |

Inner and outer ring spacers provided |

| (Angular contact ball bearing) |

| / |

spacers provided |

| /P |

Outer ring spacer provided |

| /S |

Inner ring spacer provided |

| (Cylindrical roller bearing, spherical roller bearing) |

| +DP |

Inner and outer ring spacers provided |

| +IDP |

Inner ring spacer provided |

| +0DP |

Outer ring spacer provided |

|

|

| Codes | descriptions |

|---|

| (Pressed cage) |

| // |

Steel sheet |

| YS |

Stainless steel sheet |

| (Machined cage) |

| FT |

Phenol resin |

| FY |

High-tensile brass casting |

| FW |

High-tensile brass casting

(separable type) |

| (Molded cage) |

| NG |

Polyamide |

| FG |

Polyamide |

| (Pin type cage) |

| FP |

Carbon steel |

|

|

| Codes | descriptions |

|---|

| (JIS) |

| Omitted |

Class 0 |

| P6 |

Class 6 |

| P6X |

Class 6X |

| P5 |

Class 5 |

| P4 |

Class 4 |

| P2 |

Class 2 |

|

|

| Codes | descriptions |

|---|

| A2 |

Alvania 2 |

| AC |

Andok C |

| B5 |

Beacon 325 |

| SR |

Multemp SRL |

|

|