5-5-1 Basic static load rating

Excessive static load or impact load even at very low rotation causes partial permanent deformation of the rolling element and raceway contacting surfaces. This permanent deformation increases with the load; if it exceeds a certain limit, smooth rotation will be hindered.

The basic static load rating is the static load which responds to the calculated contact stress shown below, at the contact center between the raceway and rolling elements which receive the maximum load.

- Self-aligning ball bearings 4600MPa

- Other ball bearings 4200MPa

- Roller bearings 4000MPa

The total extent of contact stress-caused permanent deformation on surfaces of rolling elements and raceway will be approximately 0.000 1 times greater than the rolling element diameter.

The basic static load rating for radial bearings is specified as the basic static radial load rating, and for thrust bearings, as the basic static axial load rating. These load ratings are listed in the bearing specification table, using C0r and C0a respectively.

These values are prescribed by ISO 78/1987 and are subject to change by conformance to the latest ISO standards.

5-5-2 Static equivalent load

The static equivalent load is a theoretical load calculated such that, during rotation at very low speed or when bearings are stationary, the same contact stress as that imposed under actual loading condition is generated at the contact center between raceway and rolling element to which the maximum load is applied.

For radial bearings, radial load passing through the bearing center is used for the calculation; for thrust bearings, axial load in a direction along the bearing axis is used.

The static equivalent load can be calculated using the following equations.

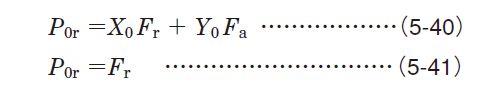

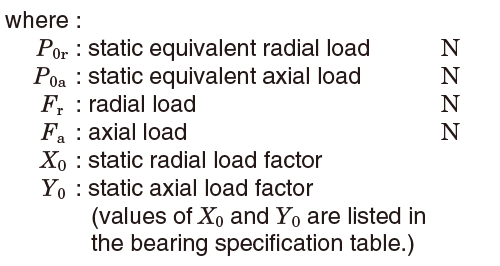

[Radial bearings]

The greater value obtained by the following two equations is used.

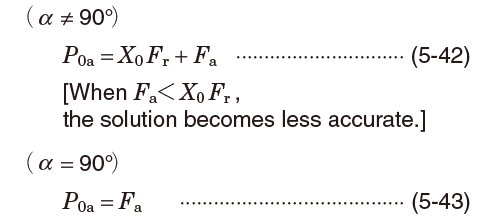

[Thrust bearings]

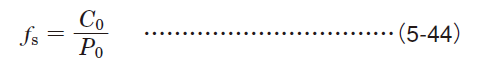

5-5-3 Safety coefficient

The allowable static equivalent load for a bearing is determined by the basic static load rating of the bearing; however, bearing service life, which is affected by permanent deformation, differs in accordance with the performance required of the bearing and operating conditions.

Therefore, a safety coefficient is designated, based on empirical data, so as to ensure safety in relation to basic static load rating.

Table 5-10 Values of safety coefficient ƒs

| Operating condition | ƒs (min.) | ||

|---|---|---|---|

| Ball bearing | Roller bearing | ||

| With bearing rotation | When high accuracy is required | 2 | 3 |

| Normal operation | 1 | 1.5 | |

| When impact load is applied | 1.5 | 3 | |

| Without bearing rotation (occasional oscillation) | Normal operation | 0.5 | 1 |

| When impact load or uneven distribution load is applied | 1 | 2 | |

[Remark] For spherical thrust roller bearings, ƒs≧4.