The amount of preload should be determined, to avoid an adverse effect on bearing life, temperature rise, friction torque, or other performance characteristic, in view of the bearing application.

Decrease of preload due to wear-in, accuracy of the shaft and housing, mounting conditions, and lubrication should also be fully considered in determining preload.

11-4-1 Preload amount of matched pair angular contact ball bearings

Table 11-2 shows recommended preload for matched pair angular contact ball bearings of JIS class 5 or higher used for machine tool spindles or other higher precision applications.

JTEKT offers four types of standard preload: slight preload (S), light preload (L), medium preload (M), and heavy preload (H), so that preload can be selected properly and easily for various applications.

Generally, light or medium preload is recommended for grinder spindles, and medium or heavy preload for spindles of lathes and milling machines.

Table 11-3 shows recommended fits of highprecision matched pair angular contact ball bearings used with light or medium preload applied.

Table 11-2 Standard preload of high-precision matched pair angular contact ball bearings

| Bore diameter No. | 7900 C | 7000 | 7000 C | 7200 | 7200 C | ACT 000 | ACT 000 B | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S | L | M | L | M | H | S | L | M | H | L | M | H | S | L | M | H | L | M | L | M | |

| 00 | 5 | 15 | 30 | 30 | 80 | 145 | 6 | 20 | 50 | 100 | 50 | 145 | 245 | 10 | 30 | 80 | 145 | - | - | - | - |

| 01 | 7 | 20 | 40 | 30 | 80 | 145 | 6 | 20 | 50 | 100 | 60 | 145 | 295 | 15 | 40 | 100 | 195 | - | - | - | - |

| 02 | 8 | 25 | 50 | 50 | 145 | 245 | 10 | 30 | 80 | 145 | 80 | 245 | 390 | 15 | 50 | 145 | 245 | - | - | - | - |

| 03 | 8 | 25 | 50 | 60 | 145 | 295 | 15 | 40 | 100 | 165 | 100 | 245 | 540 | 25 | 70 | 145 | 345 | - | - | - | - |

| 04 | 15 | 40 | 80 | 60 | 145 | 295 | 15 | 40 | 100 | 245 | 145 | 295 | 635 | 25 | 80 | 195 | 390 | - | - | - | - |

| 05 | 15 | 50 | 100 | 100 | 245 | 490 | 20 | 60 | 145 | 295 | 145 | 390 | 785 | 35 | 100 | 245 | 490 | - | - | - | - |

| 06 | 15 | 50 | 100 | 145 | 295 | 635 | 25 | 80 | 195 | 390 | 145 | 590 | 930 | 35 | 100 | 295 | 590 | 195 | 345 | 295 | 685 |

| 07 | 25 | 70 | 135 | 145 | 390 | 785 | 35 | 100 | 245 | 490 | 245 | 785 | 1270 | 50 | 145 | 390 | 785 | 195 | 390 | 390 | 735 |

| 08 | 25 | 80 | 145 | 145 | 390 | 785 | 35 | 100 | 295 | 590 | 390 | 880 | 1570 | 65 | 195 | 440 | 880 | 245 | 440 | 440 | 835 |

| 09 | 35 | 100 | 195 | 245 | 540 | 980 | 50 | 145 | 345 | 635 | 490 | 1080 | 1770 | 85 | 245 | 540 | 1080 | 245 | 490 | 490 | 930 |

| 10 | 35 | 100 | 195 | 245 | 635 | 1180 | 50 | 145 | 390 | 735 | 540 | 1180 | 2060 | 85 | 245 | 590 | 1180 | 295 | 540 | 540 | 1030 |

| 11 | 40 | 115 | 235 | 295 | 785 | 1370 | 65 | 195 | 440 | 880 | 635 | 1370 | 2450 | 100 | 295 | 735 | 1470 | 390 | 685 | 685 | 1270 |

| 12 | 40 | 115 | 235 | 390 | 880 | 1570 | 65 | 195 | 490 | 980 | 785 | 1470 | 2940 | 110 | 345 | 785 | 1670 | 390 | 735 | 735 | 1420 |

| 13 | 50 | 145 | 295 | 440 | 980 | 1770 | 85 | 245 | 540 | 1080 | 835 | 1670 | 3330 | 125 | 390 | 930 | 1860 | 440 | 835 | 785 | 1520 |

| 14 | 65 | 195 | 390 | 490 | 1080 | 2060 | 85 | 245 | 635 | 1270 | 930 | 1860 | 3730 | 160 | 490 | 980 | 2060 | 590 | 1130 | 1030 | 2010 |

| 15 | 65 | 195 | 390 | 590 | 1180 | 2160 | 100 | 295 | 685 | 1370 | 980 | 2160 | 3920 | 195 | 590 | 1180 | 2350 | 590 | 1130 | 1080 | 2110 |

| 16 | 65 | 195 | 390 | 635 | 1370 | 2350 | 100 | 295 | 735 | 1470 | 1080 | 2450 | 4310 | 225 | 685 | 1370 | 2750 | 685 | 1370 | 1270 | 2500 |

| 17 | 85 | 245 | 490 | 735 | 1570 | 2550 | 125 | 390 | 880 | 1770 | 1270 | 2940 | 4900 | 260 | 785 | 1570 | 2940 | 735 | 1420 | 1320 | 2600 |

| 18 | 100 | 295 | 590 | 785 | 1670 | 2840 | 145 | 440 | 980 | 1960 | 1470 | 3240 | 5390 | 260 | 785 | 1770 | 3430 | 980 | 1860 | 1770 | 3380 |

| 19 | 100 | 295 | 590 | 880 | 1770 | 3140 | 160 | 490 | 1080 | 2060 | 1670 | 3430 | 5880 | 290 | 880 | 1960 | 3920 | 980 | 1960 | 1860 | 3530 |

| 20 | 100 | 345 | 685 | 880 | 1960 | 3530 | 175 | 540 | 1180 | 2160 | 1860 | 3920 | 6370 | 325 | 985 | 2160 | 4410 | 1030 | 2010 | 1910 | 3680 |

| 21 | 100 | 345 | 685 | 980 | 2160 | 3920 | 195 | 590 | 1270 | 2350 | 2060 | 4310 | 7060 | 355 | 1080 | 2350 | 4900 | 1180 | 2250 | 2150 | 3770 |

| 22 | 145 | 390 | 785 | 1080 | 2380 | 4410 | 210 | 635 | 1470 | 2550 | 2260 | 4900 | 7850 | 385 | 1180 | 2450 | 5290 | 1320 | 2600 | 2450 | 4760 |

| 24 | 145 | 490 | 980 | 1180 | 2650 | 4900 | 225 | 685 | 1670 | 2840 | 2450 | 5390 | 8830 | 420 | 1270 | 2840 | 5490 | 1420 | 2800 | 2550 | 5100 |

| 26 | 195 | 590 | 1180 | 1370 | 3140 | 5390 | 245 | 735 | 1770 | 3140 | 2750 | 5880 | 9320 | 485 | 1470 | 3140 | 5880 | 1770 | 3380 | 3230 | 6230 |

| 28 | 195 | 635 | 1270 | 1470 | 3430 | 5880 | 260 | 785 | 1960 | 3920 | 2940 | 6370 | 9810 | 520 | 1570 | 3430 | 6370 | 2010 | 3920 | 3720 | 7210 |

| 30 | 245 | 735 | 1470 | 1770 | 3920 | 6860 | 275 | 835 | 2160 | 4410 | 3330 | 6860 | 10300 | 585 | 1770 | 3730 | 6860 | 2500 | 4850 | 4660 | 8920 |

| 32 | 245 | 785 | 1570 | 2160 | 4410 | 7850 | 290 | 880 | 2350 | 4900 | 3630 | 7350 | 10800 | 645 | 1960 | 4120 | 7850 | 2500 | 4850 | 4660 | 8920 |

| 34 | 345 | 880 | 1810 | 2450 | 4900 | 8830 | 325 | 980 | 2450 | 5390 | 3920 | 7850 | 11800 | 645 | 2160 | 4410 | 8340 | 3090 | 6030 | 5730 | 11100 |

[S : slight preload, L : light preload, M : medium preload, H : heavy preload]

Table 11-3 Recommended fits for high-precision matched pair angular contact ball bearings with preload applied

(1) Dimensional tolerance of shaft

| Shaft diametermm | Inner ring rotation | Outer ring rotation | ||

|---|---|---|---|---|

| over | up to | Tolerance of shaft diameter | Interference between shaft and inner ring1)(matching adjustment) | Tolerance of shaft diameter |

| 6 | 10 | - 2 | 0 - 2 | 0 |

| - 6 | - 4 | |||

| 10 | 18 | - 2 | 0 - 2 | 0 |

| - 7 | - 5 | |||

| 18 | 30 | - 2 | 0 - 2.5 | 0 |

| - 8 | - 6 | |||

| 30 | 50 | - 2 | 0 - 2.5 | 0 |

| - 9 | - 7 | |||

| 50 | 80 | - 2 | 0 - 3 | 0 |

| -10 | - 8 | |||

| 80 | 120 | - 2 | 0 - 4 | 0 |

| -12 | -10 | |||

| 120 | 180 | - 2 | 0 - 5 | 0 |

| -14 | -12 | |||

[Note]

1)Matching adjustment means to measure of bore diameter the bearing and match it to the measured shaft diameter.

(2) Dimensional tolerance of housing bore

| Housing bore diametermm | Inner ring rotation | Outer ring rotation | |||

|---|---|---|---|---|---|

| Tolerance of housing bore diameter | Clearance between housing1)and outer ring | Tolerance of housing bore diameter | |||

| over | up to | Fixed-side bearing | Free-side bearing | ||

| 18 | 30 | ± 4.5 | + 9 | 2 - 6 | - 6 |

| 0 | -12 | ||||

| 30 | 50 | ± 5.5 | +11 | 2 - 6 | - 6 |

| 0 | -13 | ||||

| 50 | 80 | ± 6.5 | +13 | 3 - 8 | - 8 |

| 0 | -16 | ||||

| 80 | 120 | ± 7.5 | +15 | 3 - 9 | - 9 |

| 0 | -19 | ||||

| 120 | 180 | ± 9 | +18 | 4 - 12 | -11 |

| 0 | -23 | ||||

| 180 | 250 | ±10 | +20 | 5 - 15 | -13 |

| 0 | -27 | ||||

| 250 | 315 | ±11.5 | +23 | 6 - 18 | -16 |

| 0 | -32 | ||||

[Note]

1)Lower value is desirable for fixed side; higher value for free side.

11-4-2 Amount of preload for thrust ball bearings

When a thrust ball bearing is rotated at high speed, balls slide on raceway due to centrifugal force and the gyro moment, which often causes the raceway to suffer from smearing or other defects.

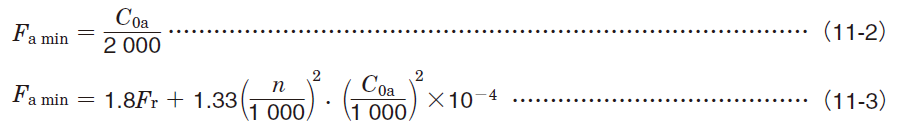

To eliminate such sliding, it is necessary to mount the bearing without clearance, and apply an axial load (preload) larger than the minimum necessary axial load determined by the following equation.

When an axial load from the outside is lower than 0.001 3C0a, there is no adverse effect on the bearing, as long as lubrication is satisfactory.

Generally, deep groove and angular contact ball bearings are recommended for applications when a portion of rotation under axial load is present at high speed.

11-4-3 Amount of preload for spherical thrust roller bearings

Spherical thrust roller bearings sometimes suffer from scuffing, smearing, or other defects due to sliding which occurs between the roller and raceway surface in operation.

To eliminate such sliding, it is necessary to mount the bearing without clearance, and apply an axial load (preload) larger than the minimum necessary axial load.

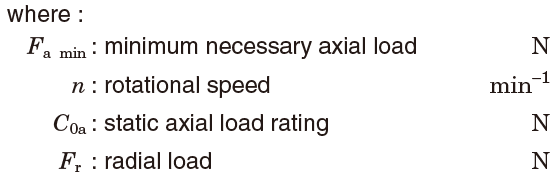

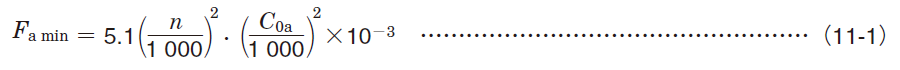

Of the two values determined by the two equations below, the higher should be defined as the minimum necessary axial load.

- Thrust ball bearing (contact angle : 90°)

- Spherical thrust roller bearing(the higher value determined by the two equations should be taken.)