After dismounting bearings, handling of the bearings and the various methods available for this should be considered.

If the bearing is to be disposed of, any simple method such as torch cutting can be employed. If the bearing is to be reused or checked for the causes of its failure, the same amount of care as in mounting should be taken in dismounting so as not to damage the bearing and other parts.

Since bearings with interference fits are easily damaged during dismounting, measures to prevent damage during dismounting must be incorporated into the design.

It is recommended that dismounting devices be designed and manufactured, if necessary.

It is useful for discovering the causes of failures when the conditions of bearings, including mounting direction and location, are recorded prior to dismounting.

Dismounting method

"Table 15-7 Dismounting of cylindrical bore bearings"

"Table 15-8 Dismounting tapered bore bearings"

"Table 15-9 Dismounting of outer rings"

describe dismounting methods for interference fit bearings intended for reuse or for failure analysis.

The force necessary to remove bearings can be calculated using the equations given on "参考:軸受の圧入又は引抜きに要する力".

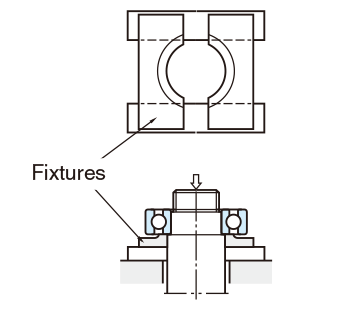

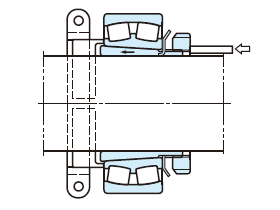

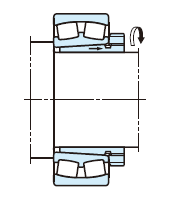

Table 15-7 Dismounting of cylindrical bore bearings

| Inner ring dismounting methods | Descriptions |

|---|---|

(a) Dismounting by use of a press

(b) Dismounting by use of special tools

(c) Dismounting by use of special tools

(d) Dismounting using induction heater |

|

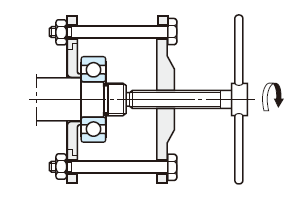

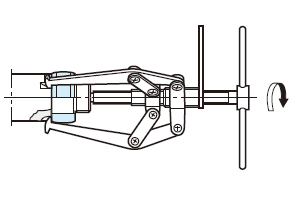

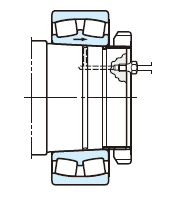

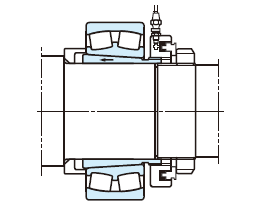

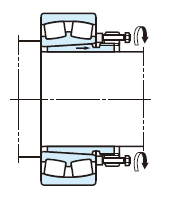

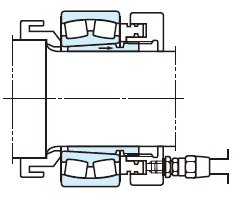

Table 15-8 Dismounting tapered bore bearings

| Inner ring dismounting methods | Descriptions |

|---|---|

(a) Dismounting by use of a wedge

(b) Dismounting by use of oil pressure

(c) Dismounting by use of clamps

(d) Dismounting by use of hydraulic nuts

(e) Dismounting by use of locknuts

(f) Dismounting by use of bolts

(g) Dismounting by use of hydraulic nuts |

|

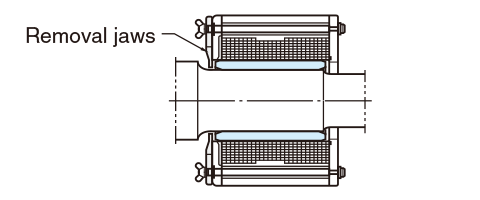

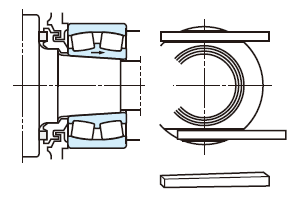

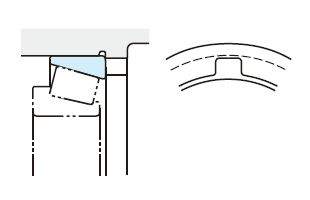

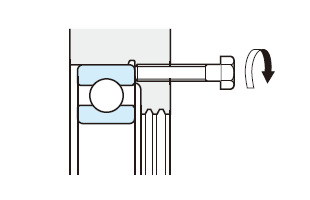

Table 15-9 Dismounting of outer rings

| Outer ring dismounting methods | Description |

|---|---|

(a) Notchs for dismounting

(b) Bolt holes and bolts for dismounting |

|