The preload can be done either by the position preloading or the constant pressure preloading; typical examples are given in Table 11-1.

〔Comparison between position and constant pressure preloadings〕

- With the same amount of preloading, the position preloading produces smaller displacement in the axial direction, and thus is liable to bring about higher rigidity.

- The constant pressure preloading produces stable preloading, or little fluctuation in the amount of preload, since the spring can absorb the load fluctuation and shaft expansion/ contraction caused by temperature difference between the shaft and housing during operation.

- The position preloading can apply a larger preload.

Consequently, the position preloading is more suitable for applications requiring high rigidity, while the constant pressure preloading is more suitable for high rotational speed, vibration prevention in the axial direction, and thrust bearings used on horizontal shafts.

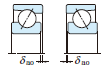

Table 11-1 Method of preloading

| Position preloading | Constant pressure preloading | ||

|---|---|---|---|

|

|

|

|

|

|

|

|